RESTON®PENDULUM – Seismic isolators

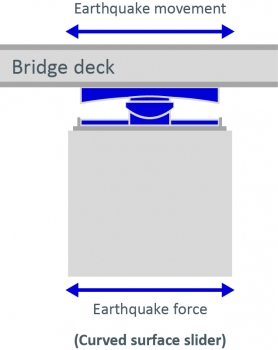

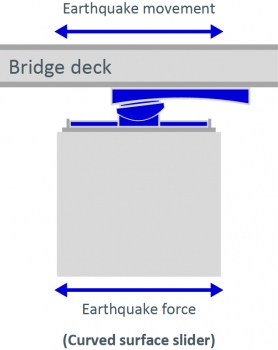

mageba seismic isolator RESTON-PENDULUM bearings are based on the functional principle of a pendulum. They allow a structure to become horizontally displaced during an earthquake, with seismic energy being dissipated by the friction between various moving components. After the earthquake, the curvature of the sliding surface of the base causes the supported structure to return by gravity to its original position.

Media

Principle

mageba RESTON®PENDULUM curved surface sliders are based on the working principle of a pendulum. They allow the horizontal displacement of a structure, providing the required shift in the natural period of the structure. Once activated by an earthquake, the isolators will allow the decoupling of the supported structure from the ground motion. After the seismic event, the restoring force due to gravity will bring it back towards the center position. The performance of the device mainly depends on its radius of curvature and the coefficient of friction.

Properties

RESTON®PENDULUM curved surface sliders reliably serve the following main functions:

- Under service conditions, the devices are designed to transmit vertical forces and allow for horizontal displacements

- In case of an earthquake, lateral flexibility is achieved through the sliding of an element along the primary curved surface

- Energy dissipation is produced by the dynamic friction between the sliding stainless steel surface and the ROBO®SLIDE high performance sliding material

- Finally, the re-centring function is given by the combination of gravity and geometry of the device's design

Seismic isolation

Seismic isolation is the decoupling of structures from ground motions induced by earthquake motions which could cause damage to the structure. To achieve such decoupling, specific seismic devices – known as isolators – are strategically installed in specific locations of structures, allowing the latter to perform properly during an earthquake.

Seismic isolators such as the RESTON®PENDULUM curved surface sliders provide the structure with sufficient flexibility so that the natural period of the structure differentiates as much as possible from the natural period of the earthquake. This prevents the occurrence of resonance, which could lead to severe damage or even collapse of a structure.

Types

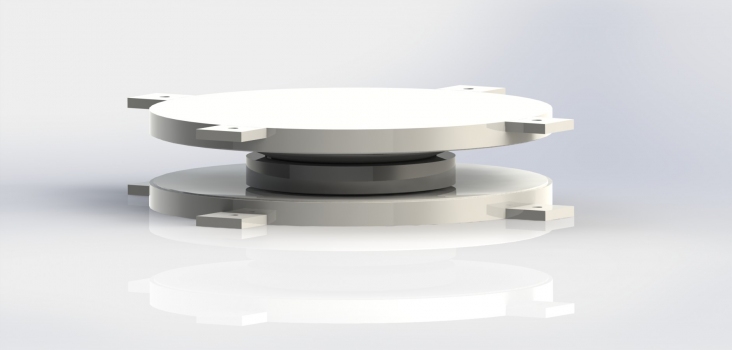

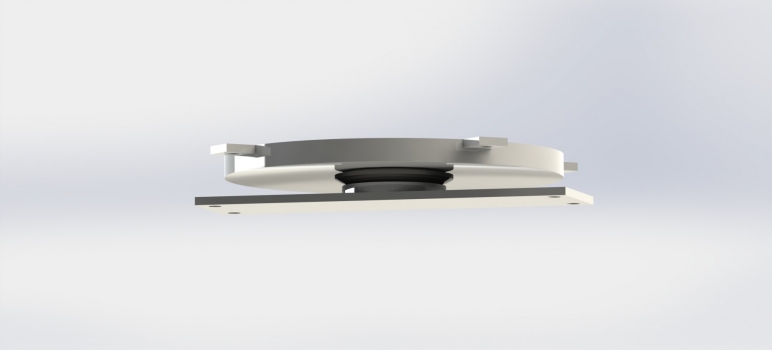

RESTON®PENDULUM Mono (PM)

mageba RESTON®PENDULUM Mono consist of three basic elements: A primary curved sliding surface, whose radius of curvature determines the oscillation period of the device, a steel element equipped with ROBO®SLIDE which slides along the primary curved surface, and a steel plate specially designed to allow the rotations of the devices. The size of the primary sliding surface depends on the required maximum design displacement.

RESTON®PENDULUM Duplo (PD)

mageba RESTON®PENDULUM Duplo includes two primary curved sliding surfaces. This allows higher horizontal displacements to be facilitated with smaller dimensions. The Duplo type includes a rocking element equipped with an articulation element that allows the bearing to accommodate rotations. This is an essential feature, especially for use with bridges which require high displacements and significant rotational capacity.

Materials

The following materials are used by mageba for the production of the RESTON®PENDULUM curved surface sliders:

- Steel parts made from S355

- Certified ROBO®SLIDE sliding material with and without grease dimples in accordance with European Technical Approval ETA-08/0115

- Certified silicone grease as lubricant

- Coating of calotte with hard chrome

- Sliding plate from polished austenitic stainless steel (grade 1.4401)

Corrosion protection

mageba proposes standard corrosion protection systems according to EN ISO 12944, with corrosivity category depending on location, environmental conditions and the required degree of protection. Corrosion protection systems according to other standards can be provided upon request.

Quality

For five decades, mageba bearings have proven their worth in thousands of structures under most demanding conditions. In addition to the product properties, the extensive experience of mageba's well-qualified manufacturing and installation staff also contributes to the high quality and durability of the products.

mageba has a process-orientated quality system that is certified in accordance with ISO 9001:2008. mageba's factories are certified for welding in accordance with ISO 3834-2, and according to the current steel construction standard EN 1090.

CE Certification

RESTON®PENDULUM bearings are designed and manufactured in accordance with European Standard EN 15129:2009 and with EN 1337. Bearings are marked with the CE mark of conformity, which confirms that they satisfy all requirements of this standard, without exception. All necessary type testing performed on RESTON®PENDULUM bearings were carried out at an independent testing facility , fully supervised by a certified body

Testing

If required by the client, a full-scale factory production control testing can be carried out. mageba performs the tests in-house as well as with independent 3rd party test institutes. Commonly performed tests are based on European Standard EN 15129:2009.

Combination

Where required by the project specifications, RESTON®PENDULUM curved surface sliders can be combined with other mageba seismic devices such as RESTON®SA Shock Absorbers, RESTON®STU Shock Transmission Units and RESTON®PSD Preloaded Spring Dampers.

mageba provides the necessary consulting for the most effective and suitable seismic isolation and damping solution.

Installation

mageba offers installation supervision for its products all over the world. The supervision is highly recommended to ensure a proper installation of the devices and to profit of the full mageba guarantee.

Careful handling of the devices is essential during transportation and installation to avoid damages.

Inspection and maintenance

Thanks to the use of high-quality components, the application of advanced design methods and a systematic internal quality assurance system, mageba seismic devices can be regarded as maintenance free.

Nevertheless, mageba recommends a visual inspection to be carried out every 3–5 years.

Upon delivery of the units, mageba submits an installation as well as an inspection and maintenance manual, allowing a regular and appropriate inspection to be carried out by the operations and maintenance staff.

Customer support

Our product specialists will be pleased to advise you in the selection of the optimal solution for your project and to provide you with a quotation.

On our website, www.mageba.ch, you will find further product information, including reference lists and tender documentation.

References

Similar Products & Services

Relevant Websites

- About this

data sheet - Product-ID

7469 - Published on:

16/02/2017 - Last updated on:

17/11/2021

mageba group

mageba group