LASTO®LRB – Lead Rubber Bearing

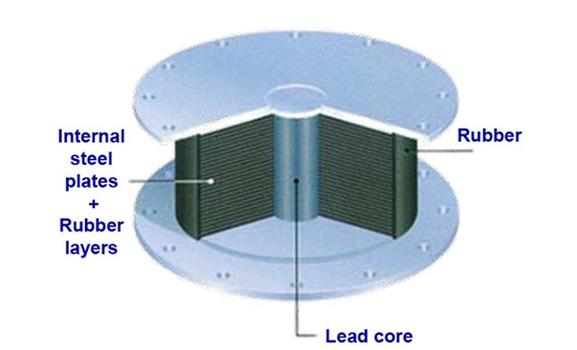

The LASTO®LRB Lead Rubber Bearing is designed to isolate the structure from horizontal ground movements due to seismic events. The bearing consists of alternating horizontal layers of rubber and reinforcing steel shims.

Media

Product summary

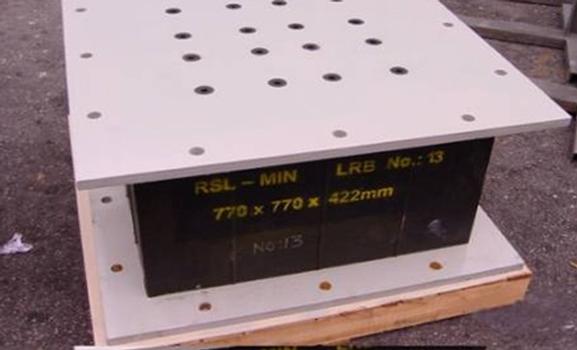

The LASTO®LRB Lead Rubber Bearing is designed to isolate a structure from horizontal ground movements due to seismic events. The bearing consists of alternating horizontal layers of rubber and reinforcing steel plates.It is fabricated with the rubber vulcanised directly to the top and bottom connection plates. The bearing can also be supplied with additional anchor plates, allowing easier replacement of the bearing.

The LASTO®LRB is made from natural rubber (NR) with a central lead plug and has great energy absorption capability.

Design principle

LASTO®LRB Lead Rubber Bearings work on the principle of base isolation and limit the energy transferred from the ground to the structure in order to protect it. The rubber/steel laminated bearing is designed to carry the weight of the structure and make the post-yield elasticity available. The rubber provides the isolation and the re-centering. The lead core deforms plastically under shear deformations, while dissipating energy through heat. Its size can be selected to produce the required amount of damping.The force displacement hysteresis loop shown is a typical characteristic for the lead rubber bearing.

Corrosion protection

Steel components exposed to the elements are corrosion protected. mageba adjusts the corrosion protection to suit exposure conditions or customer requirements. Standard corrosion protection is as follows:- Sandblasting SA 2.5

- Inorganic zinc primer (70 – 85 mm)

- Two top coatings with approved PU paint at 100-125 mm

Materials

The following materials are used for the production of mageba seismic bearings:- Reinforcing plates, top and bottom plates are made from rolled carbon steel conforming to ASTM A36 or A570

- The purity of lead is established by chemical analysis and will confirm a minimum of 99.9% purity.

- Natural rubber, type NR, grade 3 per ASTM D4014-81.

Anchoring system

Usually all LASTO®LRB are equipped with suitable anchor plates to facilitate anchoring to lower and upper structures. Alternatively, these bearings can also be supplied for connection to steel structures.Inspection and maintenance

LASTO®LRB Lead Rubber Bearings are maintenance free. The condition and position of the bearings should be inspected at regular intervals. Upon request, the mageba inspection team can carry out such inspections and summarize the results in a detailed report.References

Similar Products & Services

Relevant Websites

- About this

data sheet - Product-ID

47 - Published on:

10/01/2011 - Last updated on:

17/11/2021

mageba group

mageba group