LASTO®HDRB – High Damping Rubber Bearings

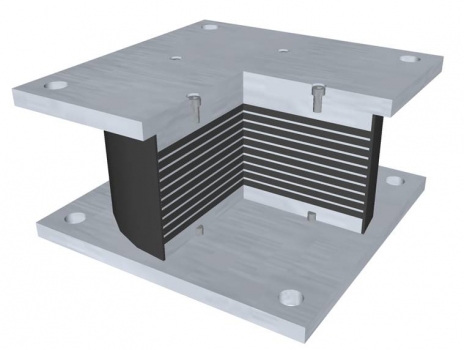

mageba LASTO®HDRB High Damping Rubber Bearings isolate a structure from the movements of the ground during an earthquake and thus limit the seismic energy acting on the structure. They are similar to regular reinforced elastomeric bearings with steel connection plates, but the elastomer material used has a special composition that dissipates seismic energy by deformation and heat generation.

Media

Principle

mageba LASTO®HDRB high damping rubber bearings work on the principle of base isolation and limit the energy transferred from the ground to the structure in the event of an earthquake. The rubber and steel laminated bearing is designed to support the weight of the structure and to provide post-yield elasticity. Rubber provides the isolation and the re-centring of the bearing after a seismic event, while reaching higher damping of up to 16%, as compared to only 5% provided by conventional elastomeric bearings.

Properties

LASTO®HDRB high damping rubber bearings consist of alternate layers of elastomeric material and vulcanized reinforcement steel plates. They provide a high level of damping of up to 16% since they are made up of a chemically improved rubber compound providing better damping and displacement capacity.

As the reinforcement steel plates are fully embedded in the elastomeric material they are sealed and thus protected against corrosion. The devices are manufactured with the rubber vulcanised to the top and bottom connection plates. The bearings can also be supplied with additional anchor plates, allowing easier replacement of the device in case of maintenance needs.

LASTO®HDRB devices are made from natural rubber (NR) providing a high resistance against mechanical wear.

Application

High damping rubber bearings find wide applications in structures. This is due to their simplicity and the combined isolation and energy dissipation functions in a single compact unit. In terms of seismic protection, this is a crucial aspect to minimising the seismic energy transfer to the superstructure and limiting the horizontal displacements of the device.

Under normal conditions, LASTO®HDRB high damping rubber bearings act as regular elastomeric bearings. Therefore, in cases of structures with limited space for bearings and seismic protection, all these functions can be combined in a single device.

High damping rubber bearings are one of the most widely used means of seismic isolation in structures and have proven effective in numerous earthquakes worldwide. The system has been researched over the past decades and offers the structural engineer a straightforward simulation of device response due to simple bilinear modelling.

Seismic isolation

Seismic isolation is the decoupling of structures from ground motions induced by earthquakes motions which could cause damage to the structures. To achieve such decoupling, different seismic devices – known as isolators – are strategically installed in specific locations of structures, allowing them to perform properly during an earthquake.

Seismic isolators provide sufficient flexibility to the structure so that the natural period of the structure differentiates as much as possible from the natural period of the earthquake. This prevents the occurrence of resonance, which could lead to severe damage or even collapse of a structure.

An effective seismic isolation system shall provide the following main functions:

- Performance under all service loads, vertical and horizontal; shall be as effective as conventional structural bearings

- Provide enough horizontal flexibility in order to reach the target natural period for the isolated structure

- Re-centring capabilities after the occurrence of a severe earthquake so that no residual displacements can disrupt the serviceability of the structure

- Provide an adequate level of energy dissipation in order to control the displacements that could otherwise damage other structural members

Materials

The following materials are used for the production of mageba LASTO®HDRB high-density rubber bearings:

- Reinforcing plates, the top and bottom plates are made from rolled carbon steel conforming to ASTM A36 or A570

- Natural rubber, type NR, grade 3 per ASTM D4014-81

Anchoring system

LASTO®HDRB devices are equipped with anchor plates to facilitate the connection of the device to the lower and upper concrete structures. Alternatively, the bearings can be prepared for connection to steel structures.

Corrosion protection

mageba proposes standard corrosion protection systems according to EN ISO 12944, with corrosivity category depending on location, environmental conditions, and the required degree of protection.

Corrosion protection systems according to other standards can be provided upon request.

Inspection and maintenance

LASTO®HDRB high-density rubber bearings are maintenance free. The condition and position of the bearings should be inspected at regular intervals. Upon request, mageba specialists can carry out such inspections and summarize the results in a detailed report.

Quality

For five decades, mageba bearings have proven their worth in thousands of structures under the most demanding conditions. In addition to the product properties, the extensive experience of mageba's well-qualified manufacturing and installation staff also contributes to the high quality and durability of the products.

mageba has a process-orientated quality system that is certified in accordance with ISO 9001:2008. Quality is also regularly inspected by independent institutes, such as the materials testing body (MPA) of the University of Stuttgart. mageba factories are certified for welding in accordance with ISO 3834-2, and according to the current steel construction standard EN 1090.

CE Certification

LASTO®HDRB high-density rubber bearings are designed and manufactured in accordance with European Standard EN 15129:2009 and with EN 1337. Bearings are marked with the CE mark of conformity, which confirms that they satisfy all requirements of this standard, without exception. All necessary type testing performed on LASTO®HDRB devices was carried out at an independent testing facility and fully supervised by a certified body.

mageba LASTO®HDRB high-density rubber bearings can also be designed and manufactured in accordance with other international specifications, such as the "AASHTO Guide Specification for Seismic Isolation Design", Japanese Specifications, National Norms, etc.

Testing

If required by the client, mageba offers full-scale factory production control testing. mageba performs the tests in-house as well as with independent 3rd party test institutes. Commonly performed tests are based on European Standard EN 15129:2009 or AASHTO "Guide Specifications for Seismic Isolation Design". For special projects, customised testing can also be performed if requested by the client.

Customer support

Our product specialists will be glad to advise you in the selection of the optimal solution for your project and to provide you with a quotation. On our website, www.mageba.ch, you can find further product information, including reference lists and tender documentation.

Similar Products & Services

Relevant Websites

- About this

data sheet - Product-ID

7465 - Published on:

03/02/2017 - Last updated on:

17/11/2021

mageba group

mageba group