RESTON®PSD – Preloaded Spring Damper

The Preloaded Spring Damper is a unit designed to dissipate seismic energy. Also it continuously recenters the struc-ture due to its tension/compression or compression/compression unit. The PSD works on the principle that the rapid passage of viscous fluid through a narrow orifice or port generates high resistance, which then dissipates a large amount of energy.

Media

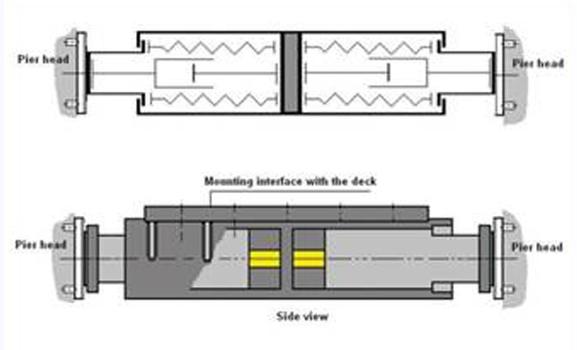

The mageba Preloaded Spring Damper (PSD) is a unit designed to dissipate seismic energy on structures such as bridges. The PSD reduces longitudinal and transverse displacement of the deck. mageba can provide two types of PSD: working in tension/compression, or acting only in compression. mageba can install the PSD compression type longitudinally between the deck and the abutment, or install a PSD tension/compression unit transversely between the deck and the pier structure. The PSD acts as a shear key which has the ability to reset itself automatically after a dynamic event. The seismic energy is dissipated in the PSD unit rather than in the main structure; additionally the seismic displacement is reduced. For general loads due to traffic, creep, shrinkage and thermal expansion or contraction, no resistance is provided up to the preloaded force of the PSD unit.

Design Principle

The PSD works on the principle that the rapid passage of viscous fluid through a narrow orifice or opening generates high resistance, which dissipates a large amount of energy. In order to prevent displacement before a certain force level is regarded, a preloaded F0 can be defined. Before reaching this value it is not possible to compress the unit. After the dynamic compression of the PSD, the unit has the ability to return to its original position due to the integrated spring function. For example, this return force value can be defined to overcome the friction force of the bridge sliding bearings. In order to generate this damping and spring function in two directions, a double-acting PSD can be used.

Anchoring System

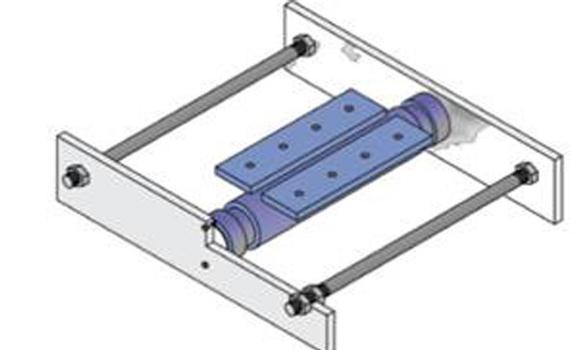

mageba Preloaded Spring Dampers can be delivered with the entire anchoring system. Depending on the bridge type, steel or concrete connections are required. For all connections, the PSD is bolted to its base plates, making them easily exchangeable.

Materials

The following materials are used for the production of mageba PSD's:

- Main outer steel parts such as cylinder tubes, cylinder pipe, etc: steel S355 according to DIN EN 10025-2

- Piston rod: steel 42CrMo4 according to DIN EN 10083-1

- Hydraulic valves: cast steel according to ISO 3755

Corrosion Protection

Corrosion protection according to DIN EN ISO 12944, C4ANV695, expected durability L (long). Target of surface roughness: Rz min 60µm, or alternatively Elcometer-roughness 2. Applied layers: Sand blasting Sa 2 ½, Zinc dust 2K-EP-primer 2-pack 50µm, MIO EP 2-pack 2x70µm, MIO-PUR, 2-pack 40µm. Total target thickness 230µm, Quality level 100% parts conform.

Sealing

The sealing represents the most critical element of the total hydraulic system. Therefore, mageba employs a high grade sealing that demonstrates virtually no wear and an absolute physical-chemical compatibility with the damper's viscous fluid.

Viscous Fluid

The mageba viscous fluid is based on a silicon oil with special additives, protecting it against natural aging and the PSD from inner corrosion.

With respect to temperature variations, the viscosity of this selected fluid shows a nearly constant characteristic. This characteristic enables the mechanical system to be thermally compensated.

Temperature and Aging

A variation of temperature, from -55°C to +80°C, does not change the amount of energy dissipated per cycle. There is no aging of the silicone fluid. The units have been tested in very severe environmental conditions, including fire.

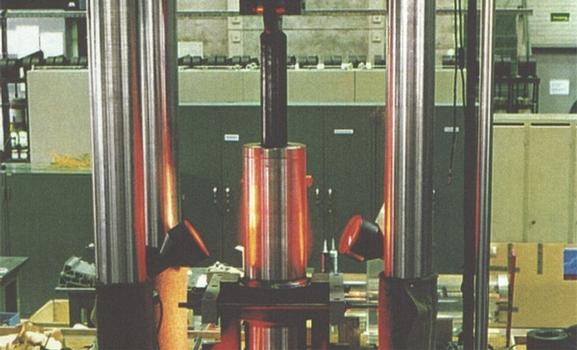

Testing

Full-scale testing can be carried out, if required. mageba performs its tests at a respected independent test institute.

Commonly used tests are:

- Damping efficiency test to evaluate the energy dissipating capability

- Constitutive law test to determine the damper's characteristic curve (force vs. velocity)

- Impressed low velocity test to evaluate the damper's axial force resistance under simulated thermal movements

Selection of Unit

The selection of the appropriate unit must be done by inserting the behaviour law of the unit into dynamic analysis software. The behaviour law of a mageba Preloaded Spring Damper is F = F0 + K*x + C*vα. This is a non-linear behaviour law.

The value of alpha can vary from 0.1 to 0.4. A modal analysis will not be possible with a non-linear model. It is necessary to run a time step analysis. In order to assist customers, mageba is able to run such a pre-sizing analysis in order to determine the most appropriate unit to protect the structure. This pre-selection must be validated afterwards by the designer. In order to do such analysis, mageba requires the main geometrical data of the structure and of the ground. The result of the analysis will provide the energy capacity required to protect the structure, and the specifications of the units required. Further information such as force induced to the structure and displacement is also provided.

Installation

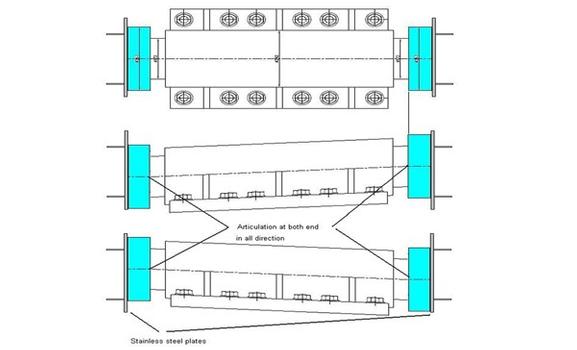

Preloaded Spring Dampers are delivered with stainless steel plates which hold the PSD in the correct position for concreting. The PSD unit is generally bolted to the lower face of the deck. Then the temporary holding bars which connect the stainless steel plates are removed by cutting. A complete installation manual is provided.

Monitoring System

An optional monitoring system is available and includes measuring units such as oil temperature gauge, distance control systems, oil pressure sensors, and so forth. The output is realised through an analogue output 4-20mA or 0-10V.

Inspection & Maintenance

Thanks to the use of high quality components and the application of advanced design methods and quality assurance system, mageba's PSD can generally be regarded as maintenance free.

Nevertheless, mageba recommends an inspection to be carried out at least every 3 years.

Upon delivery of the PSD's, mageba submits to the Engineer an inspection and maintenance manual, allowing a regular and appropriate inspection to be carried out by operations and maintenance staff.

Similar Products & Services

Relevant Websites

- About this

data sheet - Product-ID

46 - Published on:

10/01/2011 - Last updated on:

17/11/2021

mageba group

mageba group