New construction of the Schiersteiner Bridge: spherical bearings for 6,000 t of structural load

The Schiersteiner Bridge ranks among the most significant new highway bridge constructions in Germany. The challenge is the enormous structural weight causing structural loads of up to 6,000 t and large rotations.

Media

The previous highway bridge in the course of the A643 was erected in 1962 and connects Wiesbaden-Schierstein and Mainz-Mombach. Due to the considerably increased traffic volume (90,000 vehicles per day) it will now give way to a new construction comprising two parts with a length of 1,280 m and 1,285 m, respectively. The box girder bridge has three traffic lanes, one breakdown lane as well as bike lanes and walkways with a width of 21.72 m.

The first superstructure has been erected downstream since 2013, accommodating traffic in both directions since November 2017. In the meantime, the old bridge was dismantled and the second new construction, partly using the old foundation, is scheduled to be completed in 2021.

Construction highlight

The ambitious highlight in terms of construction in 2016 was the floating and lifting into position of the 120-metre centerpiece across the River Rhine. As early as in the course of planning, it had to be estimated to which movements and forces the bearings would be subjected during this complex installation process.

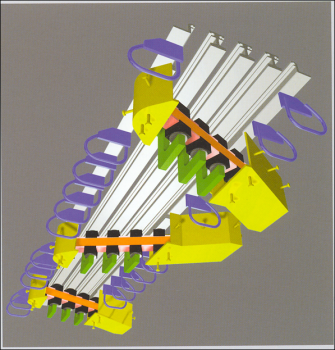

30 spherical bearings for up to 6,000 t and 1.5 % rotation

Large rotations of 1.5 % were predicted. At the same time, the bearings have to accommodate high vertical loads of more than 6,000 t. This is why spherical bearings featuring a sliding combination consisting of MSM® (MAURER Sliding Material) and stainless steel sheet were used.

The large rotations were possible due to a specially adapted inner joint, the calotte, which was manufactured from high-strength MSA® material. MSA® is a special metal alloy preventing any kind of corrosion and featuring a service life of 100 years, even under very harsh environmental conditions.

The 30 spherical bearings have been installed in the first river bridge in fall 2017.

Noise-reducing roadway expansion joints

The structure also counts with swivel joist expansion joints with noise-reduction layer on top. They bridge the structural gaps due to thermal movements at both ends of the bridge deck. At the same time, a safe and durable function must be ensured given a traffic crossing of 90,000 vehicles a day. With this type of expansion joint, the noise level when passing the bridge can be reduced by 40 to 60 %. The construction type of swivel joist expansion joints does not include components requiring extensive maintenance. The swivel joist expansion joints enable an elastic positive control creating joint gaps of equal size. Moreover, this principle allows for restraint- and fatigue-proof bridge movements in all directions over a period of 50 years and more.

The design is in accordance with the regulations, and the noise reduction has been confirmed by the Federal Ministry of Transport and Digital Infrastructure (BMVI). All load-bearing components and noise-reducing rhomboid elements at the joint surface are welded; no high-maintenance bolted connections are used.

In total, four roadway expansion joints with a width of 22 m were installed in the first superstructure. The tolerable bridge movements in longitudinal direction range between 700 mm and 1,100 mm; for a single-profile expansion joint they amount to 95 mm.

In accordance with the European Technical Approval ETA-06/0131), MSM® has a certified, high specific characteristic pressure of 180 N/mm². Even with a safety factor of 1.4 included in the calculation, high pressure of 128 N/mm² is possible on this sliding material. Hence, the dimensions of the spherical bearings could be reduced to a minimum of approx. 1,600 x 1,500 x 380 mm (up to a weight of 4,600 kg per bearing). Compared to customary bearings, this means volume savings of approx. 30 %. The friction occurring with this sliding combination is restricted to 2 % due to MSM®.

MAURER SE

MAURER SE