The Largest Spherical Uplift Bearings with CE Marking

Media

Extreme uplift forces at the Neue Strombrücke Magdeburg require special MSM® Spherical Bearings

The Strombrücke over the Elbe is of central importance in Magdeburg and has a chequered history: Originally, it was a wooden structure on stone piers, then, in 1862, an iron bridge over the river; blown up in 1945, and in 1946, reopened as a temporary bridge using old bridge elements. Since 1965, the “Neue Strombrücke” has stood in its current form. It is part of a bridge structure with a total of three bridges over the Stromelbe, the Zollelbe and the Alte Elbe.

Following rehabilitation between 1992 and 1994, the Strombrücke now had to be rehabilitated again, since the bearings, among other things, had suffered greatly. This can be explained by the special conditions at the Strombrücke.

Unequal spans: uplift forces

The bridge is almost 260 m long and approximately 30 m wide. The steel superstructure weighs 2,800 tonnes. The spans are unequally distributed: The main span is 130 m, at the abutments it is 82 and 46 m.

These unequal spans may lead to enormous uplift forces at the abutments in the case of heavy vehicles in the centre of the bridge. In addition to cars, trucks and buses, trams also cross the bridge in oncoming traffic.

Usually, bridge bearings are only designed for vertical compressive forces. Due to the special load condition, the bearings in Magdeburg were designed such that they also can accommodate uplift forces. Additionally, as is common for large bridge bearings, they also compensate for rotations and displacements.

All-rounder: MSM® Uplift Spherical Bearings

For all these load cases and movements, MAURER developed special MSM® Uplift Spherical Bearings.

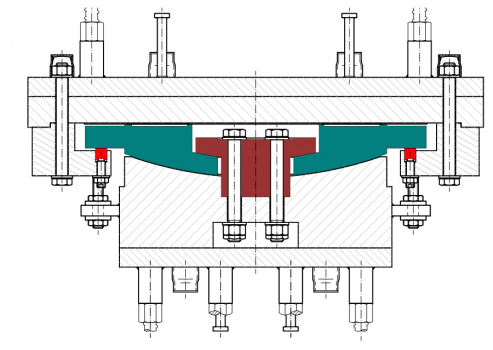

The internal calotte of the bearings has two sliding surfaces, one of which is flat, and the other in the shape of a spherical segment. This facilitates kinematic rotations and displacements of the superstructure. To enable movements of the superstructure without restraint, the sliding surfaces are equipped with the MSM® sliding material. Compared to conventional PTFE (Teflon), the “MAURER Sliding Material” accommodates higher displacement velocities and longer slide paths – virtually wear-free and with a guaranteed service life of over 50 years. Moreover, MSM® can withstand the strongly varying vertical forces without wear or fatigue. Additionally, an internal uplift device and lateral, slidable clamping devices prevent the bearings from opening in the case of uplift forces. To ensure an optimal technical functionality, the sliding surfaces must stay in contact with one another at all times.

All bearings of the eastern abutment and two of the four bearings of the western abutment protect the ends of the bridge against uplift forces of up to 4,000 kN. They also transmit rotations about the horizontal axes of up to approximately 20 mrad and movements of up to approximately 290 mm.

Limited space for installation and removal

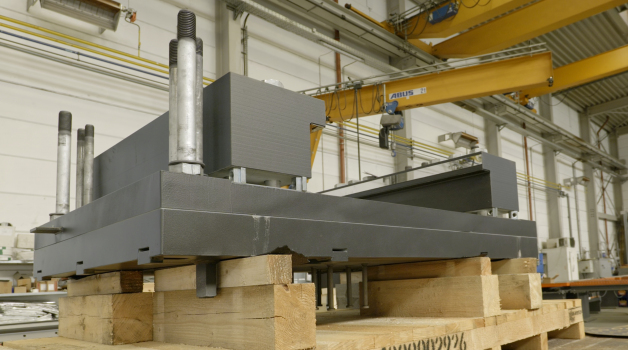

“The limited space conditions posed another challenge”, explains MAURER Project Manager Dirk Wilming. The new oversized bearings with dimensions of up to approximately 2.5 x 1.5 m and approximately 13 tonnes dead weight were installed below the existing structure, which resulted in difficult conditions. Since the old bearings had to be removed first, shores were necessary, along which the entire installation and removal had to be carried out. The bridge bearings were pre-stressed against the concrete as scheduled using specially developed tension anchors. On top of that, the bridge bearings are replaceable despite their size, which was a requirement of the owner.

The installation took place in autumn 2023; since December, the bridge has been reopened to the traffic.

References

Structure Types

- About this

data sheet - Product-ID

8049 - Published on:

22/04/2024 - Last updated on:

22/04/2024

MAURER SE

MAURER SE