Bogibeel Bridge is the second-longest combined railroad/road bridge in Asia

In 2002, construction work for the largest combined railroad/road bridge in India started. The Bogibeel Bridge owes its name to a secluded village in the tri-border region of India, Myanmar, and China, where the Brahmaputra River leaves the Himalaya.

The bridge near the Chinese border is of strategic importance to India and had already been referred to as one of several important infrastructure measures in the Assam Treaty of 1985.

The Brahmaputra is infamous for its mass of water and floods a five km wide region near Bogibeel in the monsoon season. The annual severe monsoon flooding also accounted for the long construction period. On December 25, 2018, Prime Minister Narendra Modi inaugurated the Bogibeel Bridge.

The bridge featuring a length of 4.94 km consists of 41 single-span beams, 39 of which with a length of approx. 125 m each. The railroad tracks are located at the bottom of the bridge, the two-lane road at the top.

164 spherical bearings for structural loads of 2,800 t

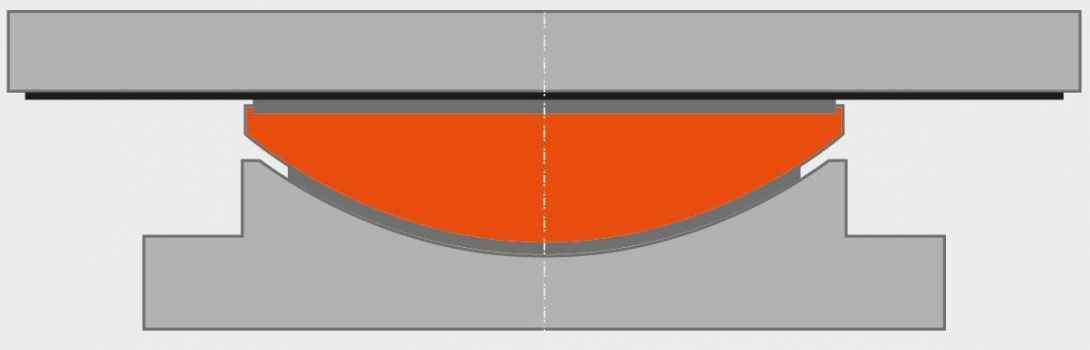

The Bogibeel order is the largest contract awarded so far for bearings to be installed in an Indian railroad bridge which is considered to be the second longest of its kind in Asia. MAURER supplied 164 spherical bearings to be placed between the bridge deck and the piers. The bearing specialists from Munich were awarded the contract because they succeeded in designing bearings capable of transmitting the extreme structural loads of 2,800 t, yet fitting into the confined space on the piers.

Confined space

Below the bridge deck, four bearings rest on each of the 41 pier caps. The bearings per area are arranged in a “classic” way: one fixed bearing, one guided-sliding bearing in longitudinal direction, one guided-sliding bearing in transversal direction, and the fourth one free-sliding. Thus the spherical bearings transmit vertical loads and allow for rotations and movement while keeping the bridge deck in position.

“The particular challenge was to dimension the bearings in such a manner that they fit onto the small pier caps,” explains Dipl.-Ing. Peter Günther, project manager at MAURER. “Space was limited both in terms of height and surface area, since the construction of the piers and the steel support structure was already too far advanced to create additional space when we received the order.” This is why there were controversial debates about the maximum permissible dimensions in the run-up of order placement.

The 164 spherical bearings feature an outline of just about 1,200 x 1,200 mm and a height of 200 mm. They are designed for a structural load of 28 MN and a horizontal force of 8 MN. The high horizontal force results from an earthquake with a magnitude of 7 on the Richter scale. A spherical joint accommodates occurring rotations of 0.02 rad around all horizontal axes without significant resistance in the bearings, which means the bearings smoothly and optimally adjust to all load and structural conditions. Thanks to the durability of the selected material that has been tested without wear for an accumulated sliding path of 50,000 m, a service life of at least 50 years can be expected. In addition, the minor sliding friction of the bearings of max. 1.5 % at bearing movements of up to 150 mm gives higher safety for the design of the bridge piers and the pier foundation in the water.

Load tests in Shanghai

The bearings were produced in Munich early in 2016, the anchor plates at the factory of MAURER India in Bhopal. In early summer 2016, 12 bearings were tested in Shanghai. The installation of the bearings started mid-2017.

Northeast Frontier Railway acted as building contractor, Hindustan Construction Company (HCC) as construction company, and DSD Brückenbau GmbH as consultant.

References

Structure Types

- About this

data sheet - Product-ID

7642 - Published on:

21/06/2019 - Last updated on:

21/06/2019

MAURER SE

MAURER SE