Bearings Slid in Piggyback-Style

Once completed, the new railroad bridge over the Drava River in Carinthia, Austria, will function with a unique combination of sliding isolation pendulums and brake dampers. The load-bearing structure slides over the bearings for slow and continuous movements with almost no resistance. When a train brakes or starts, specific brake dampers hold the bridge in place. The re-centering sliding isolation pendulums then allow the bridge to slide back again into its original position. This special combination was proposed by MAURER as a system solution.

Media

Unique combination of bearings and dampers for railroad bridge

The Jauntal Viaduct is being modernized, and a second track is being laid for the construction of the Koralm Railway. The 96-metre-high and 430-metre-long railroad bridge over the Drava River is one of the highest railroad bridges in Europe and will become operational again by the end of 2023.

The new composite structure has two tracks on top and a foot and cycle path below. The two piers on the slope and both piers in the river erected as early as 1961 have been preserved. Preliminary investigations revealed that – following minor repair measures – they can still be used for vertical load transmission. However, they must not be used for horizontal load transmission resulting from braking and starting.

At that point, MAURER was able to contribute its expertise in structural protection and jointly developed a unique overall package of re-centering bridge bearings (Sliding Isolation Pendulums SIP®) and fast-acting brake dampers (Shock Transmission Units STU) with the parties involved. All bearings and dampers fulfill the required technical service life of at least 50 years and the lowest possible coefficient of sliding friction of a maximum of 2%.

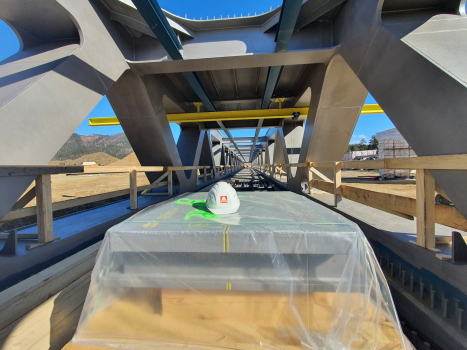

The steel structure of the new bridge was manufactured in three segments on-site at the pre-assembly place. The first segment was then connected to the existing bridge. In that way, the new bridge was slid in, and the old bridge slid out segment by segment in the longitudinal direction.

Subtle interaction

The new bearing system in the longitudinal direction required a holistic view and precise coordination of the main components of the bridge’s horizontal system: sliding isolation pendulums, brake dampers, and carriageway expansion joints. The longitudinal displacements of the load-bearing structure owing to the monotonously and gradually increasing load conditions (such as constant temperature changes in the structure) must take place without remarkable resistance and significant response force in the brake damper. At the same time, the structure's longitudinal movements must be prevented during jerky braking and starting processes. This can be done through fast-acting brake dampers in the area of the abutment, which transfer the braking and starting forces into the abutments and the ground.

Re-centering sliding isolation pendulums

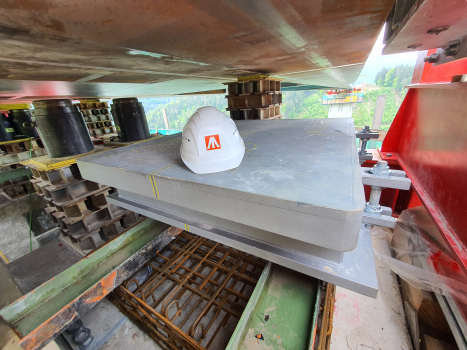

Two SIP® sliding isolation pendulums were installed in each pier, and two spherical bearings with a flat sliding surface in each abutment. Sliding isolation pendulums have a curved sliding surface that is specifically selected and adjusted to the specific application. This curvature creates a re-centering effect, enabling the system to return to its original position after deflection. With this floating support, the bridge automatically aligns itself centrally at all times.

Lowest possible friction coefficients

It was especially important that all bearings featured the lowest possible friction coefficients so that the historic piers were loaded as little as possible. In order to meet the quality requirements in terms of the high sliding and load-bearing capacity as well as the long technical service life of at least 50 years, all bearings were equipped with wear-resistant sliding materials MSM® (MAURER Sliding Material) combined with corrosion-resistant calottes MSA® (MAURER Sliding Alloy). For superimposed loads of up to 52 MN, it was possible to design relatively compact bearings with a weight of up to 2,500 kg and dimensions of up to 1,300 x 1,234 mm.

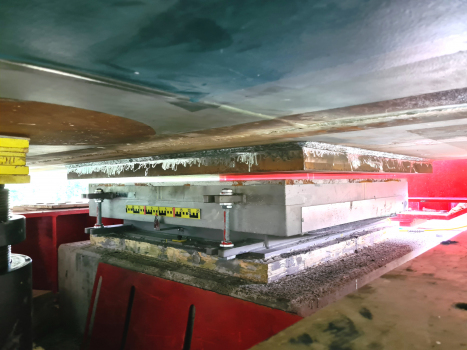

For installation, the SIP® bearings were placed on the load-bearing structure and transported to the respective piers with the launching. After the new bridge had been completely launched, the bearings were lowered to the installation site using specific mounting girders and installed in the bearing plinths. The alignment and lowering of the load-bearing structure and its positioning on the final spherical bearings and sliding isolation pendulums took place in May 2023.

The dampers and carriageway expansion joints at both ends of the bridge were installed during the summer of 2023. The bridge is scheduled to become operational, along with the timetable change, in December 2023.

“The realization of such innovative ideas requires a high level of implementation competence and responsibility”, emphasizes Dr. Saeed KARIMI, Head of the MAURER subsidiary in Austria. “We would therefore also like to thank all our partners for realizing this challenging project.” In detail, these were:

- Client: ÖBB Infrastruktur AG

- Structural designer: KOB ZT GmbH

- Substructure planner: ZKP ZT GmbH

- Consortium of test engineers: KMP ZT GmbH & Baumann + Obholzer ZT GmbH

- Execution of construction work: ARGE Jauntalbrücke (SWIETELSKY AG and Donges SteelTec GmbH)

References

Structure Types

- About this

data sheet - Product-ID

8043 - Published on:

27/09/2023 - Last updated on:

27/09/2023

MAURER SE

MAURER SE