A lift bridge is lifted off its bearings

For the new Kattwyck Bridge and the older one it replaces as a railroad bridge, MAURER was responsible for the installation of the bearings. For the lift span, the challenge was that the bearings had to be pulled apart during the lifting process and come together again when lowered.

Media

MAURER equips both the old Kattwyk Bridge and the new Kattwyk rail bridge in Hamburg

The striking Kattwyk bridge in the Port of Hamburg now has a sister bridge bearing the same name. A special feature of the new and, at the same time, largest lift bridge in Germany is that the lifting platform is raised off the structural bearings. MAURER supplied the bearings and roadway expansion joints for the new rail bridge and also replaced bearings and joints on the refurbished "old" Kattwyk bridge.

Both Kattwyk bridges across the southern Elbe (Süderelbe) in the Port of Hamburg are steelwork bridges and Hamburg landmarks. The older bridge was the largest lift bridge in the world when it was erected in 1973. Now, a 287-metre-long sister bridge, the largest lift bridge in Germany, has been built 58 m further north. The "new Kattwyk rail bridge" has a lifting height of 45.7 m and a passing width of 108 m.

When ships need to pass through, the bridges are closed to road and rail traffic, for a total of up to three hours every day. Before the new bridge was erected, road traffic had also to be stopped every time a train passed over, i.e. up to seven hours a day. The new Kattwyk rail bridge now carries the rail traffic, while the old bridge is reserved only for road traffic.

From a technical point of view, the sister bridges each consist of three partial bridges: fixed bridges on the bank sides and lift bridges in the middle. All six partial bridges are single-span structures and are thus individually supported. Two pylons each serve as supports for the fixed bridges and house the lifting equipment.

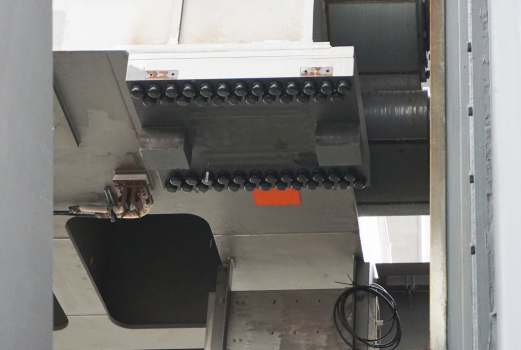

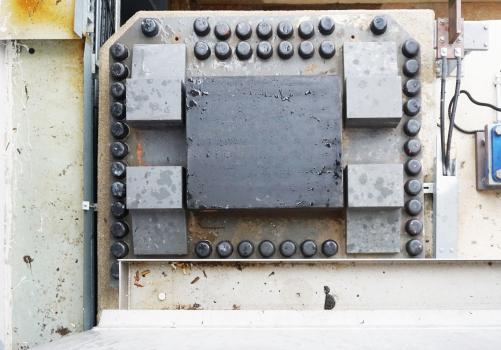

The new Bridge bearings: Restraining and recoupling

The special challenge imposed on the new 133 m long lift bridge required that the bearings separate during the lifting process, whereby the bearing upper parts move up simultaneously. After uplift, the bridge also presents a horizontal clearance of several millimetres and in addition is able to expand or contract due to heat or cold. Therefore, it has to be "recoupled" during lowering so that it comes to rest exactly on the bearings again. MAURER solved this problem by using special bearings that achieve guiding, restraining and recoupling functions within one structural element.

Six steel-reinforced elastomer bearings made of chloroprene rubber were thus installed under the lift bridge.

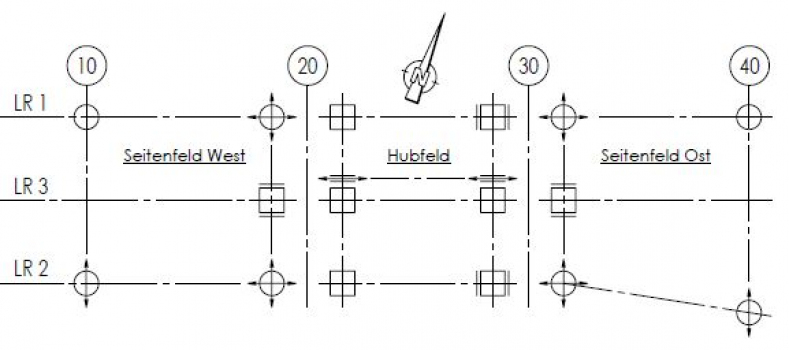

Bearing system (symbolic acc. EN1337-01) of the new rail bridge Kattwyk support system.

Bearing system (symbolic acc. EN1337-01) of the new rail bridge Kattwyk support system.

Four of these bearings are multidirectional. Two are equipped with horizontal restraints that secure the lift bridge in the longitudinal direction. In addition to accommodating and transmitting horizontal forces, these two bearings also provide a recoupling function ensuring that the bridge slides back into the exact longitudinal position when it is lowered. For this purpose, the engagement on the bearing lower part is radiused, and tooth-shaped counterparts are fitted to the bearing upper part.

Two horizontal load bearings ensure restraining and docking in the transverse direction. These bearings are located at the ends of the lift bridge span, in the middle respectively. The multidirectional elastomeric bearings that are located directly next to the transverse guide prevent any bridge deflection. They can be considered as a bearing unit. Directly opposite, on each of the fixed bridge spans, a laterally fixed elastomer bearing is installed.

Spherical bearings for fixed lateral bridge spans

The two fixed bridge spans are supported at abutment level. Horizontally held MSM®/MSA® spherical bearings are respectively located there. Spherical bearings are sliding bearings that accommodate shear strains in all directions without noticeable resistance via an inner spherical joint. They thus transmit almost tension-free forces from the bridge deck to the substructure.

The spherical calottes are made of MSA® (MAURER Sliding Alloy), a lightweight and corrosion-resistant material. MSM® (MAURER Sliding Material) is used on all sliding surfaces. The patented sliding material has, among other qualities, the advantage that, compared to PTFE, it can accommodate at least 5 times the accumulated sliding displacements and 7.5 times the sliding speed without wear. This is relevant for the new Kattwyk rail bridge because, as a steel bridge, it moves a lot, and train crossings trigger vibrations with high oscillation frequencies. On the pylon side of the fixed bridge spans, two multidirectional spherical bearings are installed. An elastomer bearing is placed in between to reduce deflection. It also maintains the bridge span in the transverse direction using restraining structures.

In addition, MAURER supplied the roadway expansion joints for the new bridge, in the form of DB-regulated elastomer mats. These joints were installed at the bridge ends and at the transition to the pylon in order to compensate for longitudinal movements of the bridge deck and dynamic structural movements. At Expansion joints of type DB130N for gap widths of up to 130 mm are located at pylon level, and expansion joints of type DB40N for gap widths of up to 40 mm are located at abutment level.

Road bridge: Swivel joints instead of elastomer

Furthermore, since 2017 the old Kattwyk bridge has been renovated and converted into a road bridge. MAURER structural bearings and expansion joints were installed in both bridges: "This shows that the bridge owner, the Hamburg Port Authority, is convinced of the quality of MAURER products," rejoices MAURER project engineer, Dirk Wilming.

Already in 2018, a total of eight pot bearings were replaced on the pylons. A renovation of the abutment followed in 2021 when the pot bearings were also replaced. In addition, the now "pure" road bridge received MAURER type DS240 swivel joists to replace the old roller shutter joints. The special feature of swivel joist expansion joints is that they are multidirectional in the transverse and longitudinal direction of travel as well as vertically. The expansion joints are 19 m long in total, including the apron plates in the walkway area. The gap width can reach up to 195 mm.

Both Kattwyk bridges have bicycle and pedestrian paths that offer a great view across the southern Elbe (Süderelbe) and the port. The new bridge was built by SEH Engineering GmbH.

MAURER SE

MAURER SE