Spherical Segment Bearings in lieu of Roller Bearings

As part of the rehabilitation of the A 81 federal motorway at the Kocher Viaduct, MAURER replaces the old roller bearings made of stainless steel with modern spherical segment bearings. The patented bearing type was developed precisely for this application and is approved by a European Technical Assessment.

Media

Kocher Viaduct is equipped with modern sliding bearings instead of rollers

The Kocher Viaduct is a nine-span prestressed concrete box girder bridge at a total length of 478 m. In order to prepare it for future requirements, it is strengthened with an external prestressing and equipped with new expansion joints, among other things. Another very important measure is the replacement of the existing bearings with modern sliding bearings. The roller bearings in the structure were replaced with 24 spherical segment bearings with a vertical force of up to 19 MN, 16 spherical bearings, and 2 horizontal force bearings.

Same plan view, more function

The special feature of spherical segment bearings is their geometric design in the transverse direction of the bridge, so that the load can be transferred from the superstructure to the piers in precisely the same way as with the roller bearings. This avoids the need for structural strengthening or reconstruction. In addition, this modern bearing type can accommodate rotations about the longitudinal axis of the bridge without any problems. Roller bearings cannot rotate about the longitudinal axis of the bridge, which is why the roller can be deformed and even break. Thanks to the high-performance sliding material MSM®, the new spherical segment bearings have a guaranteed service life of 50 years.

The rolling friction coefficient relevant for the pier load was set at 1.5% when the roller bearings were installed. The spherical segment bearings were designed with a coefficient of sliding friction of 2% in accordance with the approval; the actual friction is lower. As the sliding surfaces are protected against environmental influences, the coefficient of friction will not change in the future. In roller bearings, on the other hand, rolling friction may increase to values above 2 % due to wear and contamination.

What are the functions of a spherical segment bearing?

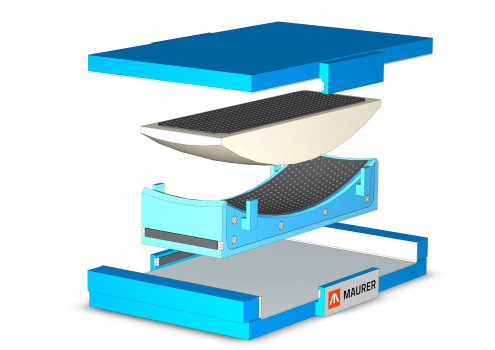

A spherical segment bearing is a modern sliding bearing that simulates a roller bearing – a “hybrid” of spherical and cylindrical bearing. When it comes to roller bearing rehabilitations, it is crucial that the friction and the geometry of the mating surfaces do not change. Additionally, the segment bearing can rotate about all axes like a spherical bearing, thus preventing the sliding material from being overloaded.

Roller bearings have a rectangular plan view. They become very wide in the transverse direction of the bridge when high loads occur, as is the case with the Kocher Viaduct. In the longitudinal direction, the roller does not require much space. In terms of forces and movements, an MSM® spherical bearing can easily replace a roller bearing, but it is either round or square. Given that after a bearing replacement the forces have to be transferred in the same way again to the greatest extent possible via the concrete structural interfaces (concrete compression/splitting tensile reinforcement), MAURER developed the spherical segment bearings ten years ago.

Segment bearings can be visualised as spherical bearings, which have been “cut off” on the right and left. At that point, of course, a number of technical challenges had to be overcome, such as: How can the curvature of the calotte be kept flat enough to evenly distribute the pressure, yet sufficiently curved so that the calotte segment cannot slip out sideways? How can the calotte segment be prevented from rotating out? In addition, the manufacture and surround of the MSM® sliding material had to be rethought, as the rectangular bearing shape complicated the geometry of the calotte segment: it is curved in all directions.

Conclusion: This modern special bearing is the optimal replacement for roller bearings, with the least possible intervention into the structure.

Autobahn GmbH des Bundes, represented by DEGES Deutsche Einheit Fernstraßenplanungs- und -bau GmbH, is the developer for the renovation of the Kochertal Viaduct on the A 81 motorway. The general contractor is the Max Bögl Group. The exchange of bearings began in autumn 2023 and is scheduled for completion in summer 2024.

MAURER SE

MAURER SE