Special bearings for the modernized Helsinki Olympic Stadium

The listed Olympic Stadium in Helsinki is being modernized which includes the addition of a new roof that covers the stands around the entire oval. This required the development of new bearings that can transfer both compressive and tensile forces.

Media

The historical Helsinki Olympic Stadium is subjected to fundamental modernization and roofing while preserving its visual appearance. In order to achieve this goal despite monument protection, architectural conditions, significant wind loads and high safety requirements, MAURER has developed special MSM® Uplift Spherical Bearings. They protect the new roof against uplift forces, accommodate high alternating loads and balance complex movements and rotations.

The stadium built from 1934 to 1938 was the venue of the 1952 Olympic Games. The stadium arena is considered the most beautiful in the world – it was the result of an architectural competition with the architects Yrjö Lindegren and Toivo Jäntti as the winners.

Renovation of the stadium

The stadium has been built and operated to this day by the Stadium Foundation. There has been some renovation work in the past, but its initial character has always been preserved and it is intended to ensure that it remains that way: particularly the view on the prominent spruce wood façade. In the interior, the fundamental renovation has been taking place since 2017: among other things, the stadium will get a warm-up hall, a shopping mall as well as significantly extended gastronomic, technical and sanitary facilities thus making it the largest event venue for sports, culture, and entertainment in Finland. The multifunctional building will offer seating for up to 36,000 spectators.

The challenge: a roof for the historical stadium

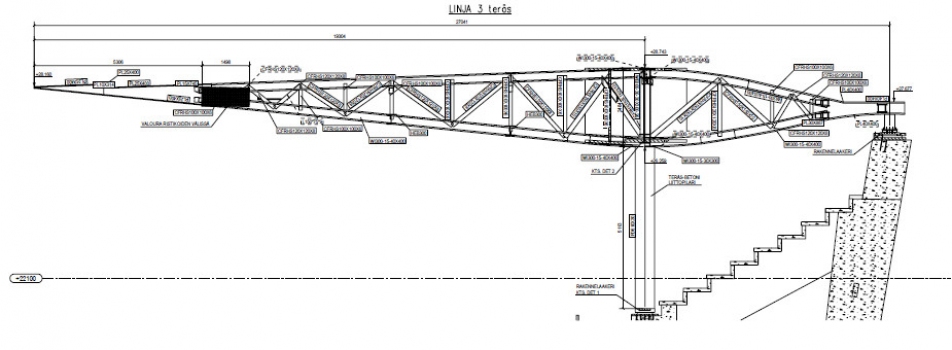

In the future, all stands are to be roofed, not just along one straight as before. Thus, the task was to fully cover the existing structure with a roof without changing the listed exterior façade. The new roof was designed as a steel skeleton structure resting on the main supports in the stands. Instead of counterweights, the crane-like cantilevers are prolonged beyond the support point and fixed at 84 bearing points on the exterior shell of the stadium, taking into consideration the required freedoms of movement.

Long list of requirements for the bearings

As the building owner, the Stadium Foundation determined the following, here abridged, requirements on the bearings:

- Alternating vertical compressive and tensile forces

- Torsions and horizontal freedom of movement

- Temperature-resistant from -36 °C to +50 °C

- Limited geometry

- Service life of more than 50 years

- Highest safety requirements

“That presented a challenge, even to us as bearing specialists,” admits Dirk Wilming from MAURER, in charge of Northern Europe in Lünen. “The crucial solution components were the uplift spherical bearings and the MSM® sliding material, both of them in-house developments by MAURER.”

MSM® resolves lack of space

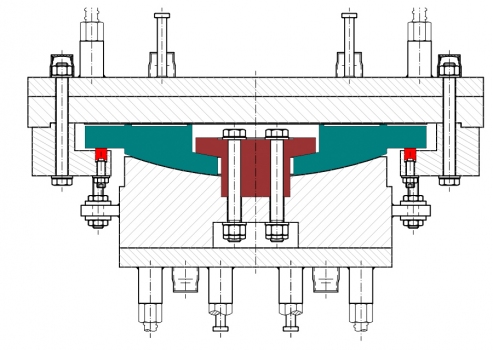

Monument protection and the given architecture limited the size of the bearings. Large dimensions of the 84 upper bearings had to be avoided in order not to disturb the exterior appearance of the spruce wood façade. Likewise, there was very limited space available for the bottom supports of the main pillars on the stand steps. However, the main bearings positioned there had to accommodate alternating loads of -12.000 kN pressure up to +3.000 kN tension, with simultaneous rotations up to 0.010 rad under horizontal loads due to the light-framed steel construction and high temperature fluctuations. These specifications were even exacerbated by the high safety requirements. The permissible Eurocode maximum loads were reduced to 80% which means: all bearings had to be computationally designed for 25% additional load which made it even more difficult to adhere to the maximum possible sizes.

The only option to meet these requirements was the use of MSM® sliding material. In comparison with customary PTFE (Teflon), “MAURER Sliding Material” accommodates twice the loads at equal size and is capable of accommodating strongly varying vertical loads without wear or fatigue. The main pillars in the stand curves rest on 11 uplift spherical bearings featuring a diameter of 1,500 mm each.

Uplift spherical bearings protect against uplift forces

The special wind conditions at the Helsinki stadium which is located near the sea and the special support structure of the roof result in complex forces and movements.

Usually, high compressive load acts on the bearings of the main pillars in the middle stands since these supports carry the entire roof. At the external support point behind the uppermost stands, however, mainly tensile loads occur since the main weight of the roof pulls downward due to the leverage effect at the main support points inside the stadium. However, when gusts of wind hit the stadium, the compressive and tensile forces reverse. The upper bearings are subjected to compressive load and the bearings in the main pillars to tensile load.

Thus, the roof had to be protected against uplift forces. For this reason, the MSM® Spherical Bearings were complemented by a tension core and lateral holding devices capable of sliding. In addition, the specially designed uplift spherical bearings enable the transfer of vertical compressive and tensile loads virtually without restraint in any rotation and displacement condition. “Our MSM® uplift spherical bearing is the only one that meets these requirements,“ explains Wilming.

Number and positioning of the bearings

A total of 95 bearings in 12 different designs were built for the stadium roof in Helsinki. They were partly adapted to the respective requirements of the bearing points in a multi-stage development and adjustment process.

The 11 bearings accommodating the highest loads are positioned at the bottom of the main pillars in the stand curves and are fixed bearings. The 84 upper bearings are fixed, guided or free-sliding bearings. Ten of them feature a simpler design, not as uplift spherical bearings but as a twin construction: virtually two bearings placed on top of each other that are protected against uplift forces through connecting girders.

Service life of more than 50 years

The requirements on the bearings as specified above are met through the use of MSM® on all sliding surfaces. The outstanding characteristic is a service life of more than 50 years. The abrasion of the sliding material tends towards zero, even at high accumulated sliding paths. In addition, MSM® meets the required temperature resistance from -36 °C to +50 °C and beyond.

Additional approvals and tests

The bearings comply with a huge number of regulations and requirements. The special uplift spherical bearings were designed based on MSM® Spherical Bearings in accordance with ETA-06/0131. The individual components are marked with the CE sign. The special bearings were meticulously examined through FE calculations, tests, and ultimate limit state analyses. Moreover, they were approved for compliance with the Finnish regulations. The procedure corresponds roughly to the “Zustimmung im Einzelfall” (special individual approval) granted by the German building authorities.

Manufacturing, delivery, and installation took place in 2017/2018. The inauguration of the stadium is planned for 2021.

References

Structure Types

- About this

data sheet - Product-ID

7656 - Published on:

11/12/2019 - Last updated on:

11/12/2019

MAURER SE

MAURER SE