Replacing pot bearings with spherical bearings in Vienna

For the Viennese, the Reichsbridge is a structure that causes special emotions. Today's bridge is already the third one at that location. Its predecessor was a landmark of Vienna. Moreover, after World War II, it was the only undamaged bridge in Vienna and its vicinity. This bridge collapsed in 1976, caused by a concatenation of technical circumstances that could not be anticipated with the know-how at that time.

Combined Traffic

On November 8, 1980, the new Reichsbridge was opened for traffic. The design is adapted to the urban layout with a plain and uniform architecture. Today the bridge is one of the most important Danube crossings in Vienna and links the second district (Leopoldstadt) with the 22nd district (Donaustadt). On its side to the centre, the bridge leads via the Lassallestrasse to the Vienna Prater and its landmark, the giant observation wheel. When driving northwards, you can view the headquarters of the United Nations in Vienna.

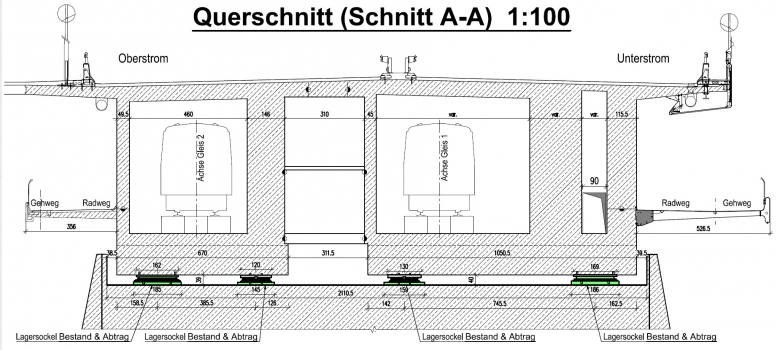

The Reichsbridge is a double storey and prestressed box girder bridge. On its lower deck, it accommodates two subway tracks as well as two side lanes for the pedestrians and the bicycles. The upper deck of the bridge contains each three traffic lanes per direction. Moreover, numerous service pipes are installed.

Pot bearings had to be replaced

In the course of the periodically occurring maintenance check of the bridge structure, it was noted that the sliding clearings of the bearings in axes P7 and P10 were below the permitted limits. Four original pot bearings were arranged on each of these axes. Now they were replaced by high-performance spherical bearings.

Caused by the intensive use of the bridge, considerable support forces of up to 54 MN had to be accommodated, which is a rather rare case for an inner city bridge. The challenge was to take out the old pot bearing within the constraints of the space and to install state of the art spherical bearings which conform to today's standards.

Because it was proven that in both technical and economic aspect the MAURER spherical bearings with the sliding components MSM® and MSA® were the best on the market, the supply contract was awarded to MAURER.

High Durability thanks to MSA®

The calottes consist of MSA® (MAURER Sliding Alloy), which is a special metallic alloy for structural bearings. They display their superiority by way of a special corrosion protection and are very durable against pollution.

High support forces, high accumulated sliding displacement, and high displacement velocity

The sliding material of the spherical bearings consists of MSM® (MAURER Sliding Material). In relation to PTFE, it accommodates at least the double contact pressure, the five-fold accumulated sliding displacement, and the 7.5 fold displacement velocity. In combination with MSA®, MSM® facilitates sliding friction coefficients of less than 1 %. With these performance characteristics, it was possible to design these bearings for a support force of up to 54 MN which could fit into the available constrained space.

Low friction coefficient protects the substructure

Moreover, these bearings stand for durability. This durability not only applies to the bearings and their sliding surfaces but also for the structural protection in general. The extremely low friction effects an almost resistance free bearing displacement. This translates into a minimum strain for the substructure, thus increasing its service life.

A total of eight bearings were installed, four each at the two piers P7 and P10. They measure 1350 mm x 1350 mm and have a weight of 1.5-3.3 tons.

The first bearings were replaced in October 2016 at pier P10, here was the best accessibility. In case of pier P7, at the Danube side pontoons had to be employed.

A special praise shall be given to the installation team. "My admirations for the team of STRABAG" emphasizes Saeed Karimi, head of MAURER Austria. "Most of the time they had to work lying." Owner of the project was the department MA29 (Bridge Construction) of the Vienna City Government.

MAURER SE

MAURER SE