New expansion joints: Silent Waves

Large renovation works were due to one of Munich's highly trafficked bridges, which also includes the replacement of two profile joints. Maurer Söhne came up with a quite unique proposal: to install for the first time the product innovation MAURER XW1 Expansion joint: XW 1 joints are one-piece expansion joints with a gap between 5 mm and 100 mm, to be designed in a wave shaped line.

Wave shaped and stainless

"This innovation combines the advantages of 2 other well proven products", explains Dipl.Ing. Oliver Nagel, project manager at Maurer Söhne. "We have combined the relatively simple design principle of the single seal joint – 2 edge beams plus 1 strip seal – with the advantages of the reduced noise emission and a gap width of up to 100 mm that we already have at our XL1 joints. What is new and characteristic is both the form and the structure. Whereas at the XL1 joint, the waves were rather "jagged" and its edge plates were bolted, the new edge beam XW 1 runs wave shaped and is continuous. In addition, at the Donnersberger Bridge the new expansion joint employs a corrosion protection in a hybrid manner. The upper part of the edge beam is made of stainless steel ("white") and changes further down to conventional ("black") steel. The latter in order to guarantee an optimum welding connection with the anchor plate.

The main effect of the noise reduction can be owed to the wave shape. The wheels of an axis do not hit the edge of the joint simultaneously, but this edge is being hit from a skew direction at least by one of the two wheels. Furthermore, the term "edge" may not apply any longer, because the installation of the edge beam must be carried out level with the asphalt, and not, as it is usually required, with the asphalt being set a few mm above the edge. This installation mode reduces the noise emission, however it requires a very exact installation of the asphalt. This lends the XW 1 joint an additional advantage. The wave acts like a template, stabilises the asphalt, and makes strengthening ribs redundant, which are required with conventional profile types.

In addition, the continuous design mode saves the checking of bolted connections and facilitates the self cleaning effect of the expansion joint. The patented, one-piece and flexible sealing element ensures the watertightness of the expansion joint. Putting it all together, the new XW 1 joint is maintenance free. Furthermore, the wave shaped design prevents damages caused by snow ploughs.

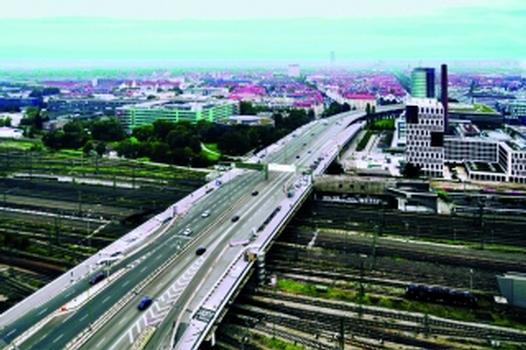

The first installation of these expansion joints was carried out in the months of August/October 2010 at the ramps leading to the Donnersberger Bridge. Due to the central importance of the bridge, traffic flow was continuing at one lane. After installation, the 2 separate parts of the expansion joints were welded together. The new expansion joints accommodate movements of up to 100 mm and reduce the noise emission for the neighbourhood.

MAURER SE

MAURER SE