New bridge Hisingsbron (Gothenburg): Noise-reduced expansion joints with special “tunneling”

A streetcar running on a bridge is not uncommon. However, this presents a challenge in Gothenburg since long ramps lead to the bridge construction. The required expansion joints between the structural sections have to be watertight and noise-reduced and must be usable for all road users in the streetcar track area. MAURER developed a customized solution for the roadway expansion joints with a length of up to 43 m.

Media

In the city center of Gothenburg, the Götaälvbron has been spanning the river Göta since 1939. The most important bridge of Gothenburg leads directly to the city center, but the bascule bridge will vanish soon. Only a few meters next to it, the Hisingsbron has been under construction since 2017, named after the island located north of the bridge. While the previous Götaälvbron with its huge clearance height gives the impression of a break in the city, the Hisingsbron which is lower in height is intended to form part of a new urban life: with broad pedestrian paths, bikeways and scenic outlook areas as well as connections to the riverwalk. Fallow dockyard and port areas in the neighborhood are to become modern residential and shopping areas.

Hisingsbron can be uplifted by 28 meters

Architects Dissing+Weitling from Copenhagen won the architectural competition in 2013 with their design of a lift bridge. The main bridge featuring a length of 48 meters can be uplifted by 28 meters along four white pylons. Long ramp constructions lead to the bridge, partly equipped with two roadway levels. The ramps feature different cross sections, they provide up to five car traffic lanes, two streetcar tracks, four bikeways, two pedestrian ways and scenic view platforms. The total length of the bridge including access bridges is 460 m.

The bridge was initially planned to be completed by 2021, the 400-year anniversary of the city of Gothenburg. However, the corona pandemic caused delays, for instance since qualified technicians were not allowed to travel to Sweden without a quarantine time. Therefore, the first roadway expansion joints were installed in June; additional joints are to be installed by 2021.

Complex requirements for the expansion joints

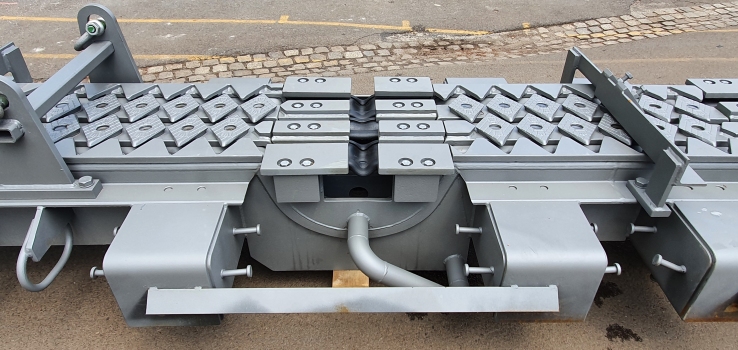

Ten expansion joints bridge the gaps between the various bridge and ramp sections. They have been and will be built in by MAURER until 2021: from the one-profile XL1 up to the four-profile XL 400. The longest one has a length of 43 m. Because of the inner-city urban utilization goals, all expansion joints have been designed noise-reduced by means of welded-on rhomboid elements. An important issue besides noise reduction was watertightness – also in places where the streetcar tracks intersect the girder sections. And it goes without saying that the expansion joints must perform the required movements under optimum control.

Initially, finger joints were planned, with which, however, watertightness could not be achieved. Construction engineer Holger Redecker, head of the subsidiary in Lünen and in charge for Northern Europe, explained:

“We were involved in the planning right from the start, thus enabling us to present an optimum solution. We have used the principle of noise-reduced modular expansion joints as a construction basis and adapted it to the requirements for the Hisingsbron.”

U-shaped streetcar track tunneling

What finally came out was an expansion joint system with “track tunneling”. In places where the normally straight profiles would be intersected by the streetcar track, the profiles provide a U-shaped tunnel for the tracks. Usually, such track tunnels are built angular-shaped. However, rounded shapes ensure better watertightness and can be cleared out more easily during cleaning.

The U-shaped tunneling is an elegant solution for the streetcar tracks – however, the Hisingsbron must be safely usable anywhere for all road users. To bridge the gap between the tracks and the U-tunnel margins, fitting pieces were screwed in, which can be dismantled for cleaning purposes.

Watertightness and drainage

Specially designed jaw edge profiles ensure watertightness. They were heat-bended to a U-shape and installed underneath the streetcar tracks.

In order to prevent water accumulation at the deepest spot of the U-tunnel, a drainpipe is welded on at the end of each tunnel that discharges the water into the sewer system. The connection of the drainage to the structure required intensive coordination with all other crafts and is an example for the complexity of these expansion joints.

Shortness of space for joist boxes

The uniform distances between the individual steel profiles (central beam, steel edge profile) of an expansion joint are ensured by means of control springs that are installed in so-called joist boxes. However, due to the track tunneling the joist boxes cannot be placed arbitrarily. Sufficient height is only available in places where no track is installed above. Normally, six joist boxes would suffice for the streetcar line with a width of a good 8 m. However, since the maximum possible distances could not be fully exploited due to track tunneling, ten joist boxes each control the distances between the profiles.

Strong focus on noise reduction

Considering the urban character of the new Hisingsbron and the planned residential development nearby, noise reduction was an important issue. MAURER was able to contribute its decades of experience in this field. A system with welded-on rhomboid elements is used. They are not only particularly efficient in terms of noise reduction, in addition, the special welding process is extremely durable and thus safe and sustainable.

References

Structure Types

- About this

data sheet - Product-ID

7683 - Published on:

07/12/2020 - Last updated on:

14/09/2021

MAURER SE

MAURER SE