Maurer Söhne obtains ETA for XW1 and demonstrates a considerable decrease in noise emission.

The CE mark for expansion joints was not yet compulsory, and a harmonised guide line for CE marking still missed. But in this situation of radical change Maurer Söhne did not hesitate a minute and applied the first European Technical Approval (ETA) according ETA-Guideline 032 for expansion joints made of steel and elastomeric material.

In order to obtain this ETA, quite different proofs have to be carried out as it would have been necessary when obtaining the General Approval in Germany. Although the German Institute of Civil Engineering in Berlin (DIBt) will remain the relevant local approval authority, but after this first local approval the application for obtaining this ETA is being passed to all other European approval authorities. Maurer however had made their homework, and in consequence the wave shaped XW1 expansion joint, which is the youngest product in the Maurer family of expansion joints, was approved. Now XW1 expansion joints with their production site in Munich, Bernsdorf and Torbali will be equipped with the CE mark.

Noise measurements demonstrate distinct advantages

The XW1 is not just any expansion joint, but with its wave shape it follows a totally new design. As a single seal expansion joint it not only displays a larger movement capacity than conventional and "straight" expansion joints, but it emits also less noise. In order to prove this case, in cooperation with the University of the Armed Forces in Munich, Maurer Söhne established a test track for noise measurements. These measurements were conducted by the expert company Müller-BBM GmbH.

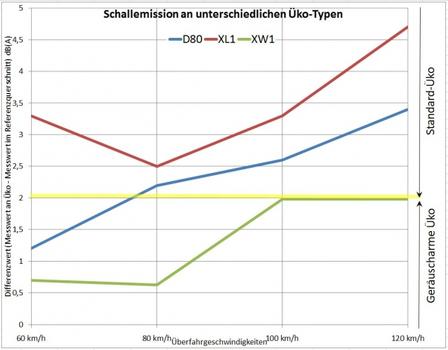

Comparisons were made with a expansion joint according to the specification drawing ÜBE1 (D80) and a same joint with bolted and toothed plates on top (XL1). The test setting followed the procedure of the "Controlled passing by" according to the Austrian Regulation RVS15.04.52, which relates to the "Judgment of noise emissions of expansion joints". The expansion joints were passed with 4 different velocities: 60, 80, 100 and 120 km/h. Noise measurements were made 30 m in front of the expansion joint and directly at the joint. The regulation rules that in case the difference of the noise emission of those 2 measurement spots is less than 2 dB(A), an expansion joint can be branded as "low noise emission".

The result leave no doubt: The XW1 is of low noise emission, and it emits less noise than a conventional D80 strip seal joint and the XL1 joint.

Wave prevents maximum level

Major reason for this excellent performance is the wave shaped profile: When an expansion joint is passed, the maximum noise emission will occur when both wheels hit simultaneously the steel rails in perpendicular direction. And exactly this "worst case" turns to become exceptional when passing a wave. The wheels very rarely hit the steel rails in simultaneously, and anyway usually hit the steel rails in skew direction. Due to the fact that an XW1 entails many different hit-scenarios, double as many measurements were made as compared to the other 2 design types.

A wave being more good-natured if the adjacent asphalt is higher

The details of the measurements revealed interesting insights. Of deciding importance for the reduction of noise emission is not only the geometry of the expansion joint, but also its installation. In case the adjacent asphalt touches at a 5mm higher level, as it corresponds to the present regulation, this results in a distinct edge and consequently in a measurable higher noise emission. In the light of this installation detail, the XW1 is much more good-natured towards the real asphalt level increases.

A very distinct superiority of the XW1 over the XL1 with its bolted and toothed noise protection plates could be noted. Reason is not only in the perpendicular hit, but also in the width of the "disturbance area". The wider this disturbance zone, the bigger the noise emission, because the tyres deform more strongly when the passing takes more time. The XL1 is double as wide as the XW1 and in comparison to the XW1 displays an inferior performance in reduction of noise emission, and even so when comparing with a conventional D80 strip seal joint.

Structure Types

- About this

data sheet - Product-ID

7115 - Published on:

08/04/2014 - Last updated on:

19/05/2017

MAURER SE

MAURER SE