Guided Cross-Tie: Highly innovative railway joint for extreme demands

Guided Cross-Ties are an innovative expansion joint system that has only been used on railway bridges a few times worldwide. The new Champlain Bridge over the St. Lawrence River boasts one of the largest ever made. The earthquake-proof Guided Cross-Ties were also equipped with a newly developed anti-derailment device.

Media

MAURER constructs large Guided Cross-Tie and unique anti-derail device for railway bridge in Montreal

The new 3.4-kilometer-long “Samuel de Champlain Bridge” over the St. Lawrence River replaces the original Champlain Bridge built in 1962. With its white, 170-m high tower and the asymmetric cable stays in a harp arrangement, it is a landmark for Montreal and is already regarded as an icon. The main span is 240 meters long, and with a total width of 60 meters, the deck is split into three parallel sections. Every year, up to 60 million vehicles cross the St. Lawrence River at this point.

Roadway traffic has been flowing on the two outer decks, each with four lanes, since 2019. The northern deck also has a multi-purpose lane for cyclists and pedestrians. Construction is still underway on the central deck section that passes in between the two towers. This section will accommodate the new automated Réseau Express Métropolitain (REM) light rail system which is scheduled to become operational in fall 2022.

Large movements combined with rotations

The expansion joints on the central deck section were a particular challenge. Its slender deck design results in relatively large longitudinal movements when trains are crossing, braking, or accelerating. Strong winds, extremely cold winters, and potential earthquakes have to be considered, too. “The relatively large vertical movements combined with rotations due to torsion and bending effects plus horizontal displacements were a challenge that could only be met with our new Guided Cross-Ties,” reports Stefan Vollert, development engineer at MAURER. But there was a whole host of other performance requirements for the expansion joint system:

- Absolutely watertight across the entire width of the deck (even in combination with the cover plate joint, named SP expansion joint) thanks to a patented rubber sealing profile

- Can be inspected from below without interrupting traffic

- Suitable for installation within the solid slab track on the concrete deck

- Perfectly uniform gap opening and closing behavior

- Temperature operation range from -35 to +40°C

The Canadian Railway Authority was aware of the technical capabilities of Guided Cross-Tie expansion joints because representatives had visited the MAURER factory in Munich two years ago. At that time the world’s first earthquake-proof Guided Cross-Ties for the Toluca-Mexico City railway line were being manufactured and it was demonstrated that the Guided Cross-Tie can meet all the performance requirements for the new Samuel de Champlain Bridge.

Expansion joints for railway bridges

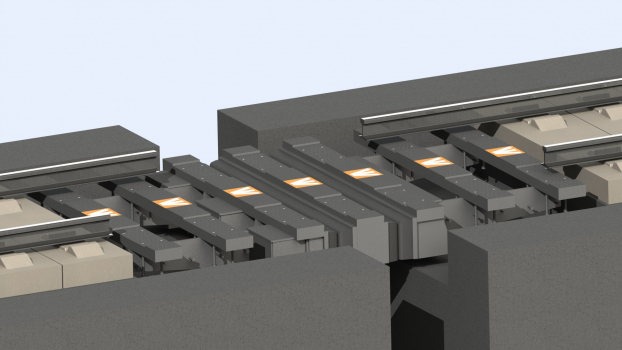

Guided Cross-Ties are expansion joints for railway bridges. They bridge the structural gap at bridge ends or between bridge sections, in Montreal for example in front of and behind the main spans at the tower, and allow movements and twisting in all directions. The Guided Cross-Tie is based on the principle of the swivel joist expansion joint for roadway bridges. However, it is much more robust because large axle loads act on the joint system every time a train passes over. These rapid vertical forces and the associated movements are transmitted without causing fatigue within the Guided Cross-Tie. Longitudinal deck movements are evenly distributed between the ties via a geometric guide control system. In contrast to an elastically guided control system, this provides more accuracy, stability, and thus longer service life.

In addition, the movable bearings in the expansion joint allow the ties to “travel” and rotate about the longitudinal, transverse, and even vertical axis. No significant elastic deformations occur within the Guided Cross-Tie when a train passes over. Even large dynamic movements caused by an earthquake can be accommodated without damage to the expansion joint allowing train traffic to resume immediately. The Guided Cross-Tie is currently the only railway expansion joint that can transmit and absorb rapid, pulse-like, and large seismic movements without failing of any joint components or of the bridge structure.

Individually designed

The challenge for this project in Canada was that the calculated movements were larger than allowed by German regulations and also larger than within the standard Guided Cross-Tie joints previously developed by MAURER. “Since all bridge movements are beyond the established codes, we had to carry out special verifications for the rails and rail fasteners,” explains Vollert.

A further requirement was that the usual anti-derail device on railway bridges had to be integrated into the expansion joint. These systems are primarily used to protect the bridge deck in the event of a derailment of an individual train axle. MAURER, therefore, developed a new anti-derail system for large bridge movements that is compatible with the Guided Cross-Tie.

High-performance sliding material MSM®

Small, laterally guided MSM® slide bearings ensure low-wear, controlled, and almost frictionless sliding of the ties with minimum resistance. MSM® stands for “MAURER Sliding Material” and was developed and patented by MAURER. Compared to conventional Teflon (PTFE), it can accommodate twice as much pressure, achieve 5 times the accumulated sliding displacements without wear and withstand displacement velocities 7.5 times faster. That is why MSM® is installed as a durable and low-friction slide bearing at all bearing points.

The new Samuel de Champlain Bridge is expected to have a lifespan of 125 years, while a minimum of 30 years was required for the Guided Cross-Ties. In fact, MAURER Guided Cross-Ties are designed to last for at least 60 years. The durability of the control system and the load-bearing components was verified in a 10-km sliding displacement test. The test was conducted with an original large CT4 (CT4 = Guided Cross-Tie with four joint gaps) in accordance with the requirements of RIL804 in an independent laboratory at the Munich University of Applied Sciences, which is certified as a third-party inspector. Testing confirmed there was no wear nor fatigue in the moving parts.

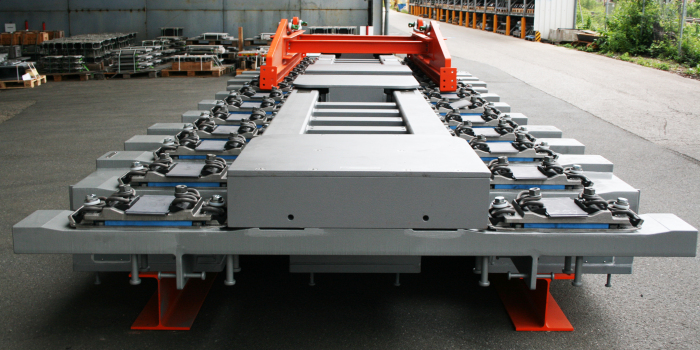

A total of 16 Guided Cross-Ties joints with anti-derail devices were manufactured in Munich. Four joints were the large “CT4” model with a movement of up to 1,030 mm.

Transport and installation devices

The Guided Cross-Ties are supplied with a specially designed transport frame. The expansion joint can be shifted longitudinally within the frame which makes it easily possible to adjust its length to match the current displacement condition of the bridge during installation on site.

To increase the speed and accuracy of the positioning procedure of the Guided Cross-Ties, six mounting feet devices per expansion joint are fixed on the structure side and adjusted in place before placing the joint onto them. This procedure saves the operating time of heavy lifting equipment.

The 16 Guided Cross-Ties were installed between November 2020 and April 2021. For fastening the rails to the joint, each tie was equipped with special rail fasteners (BSP FF-B-2-RE from Schwihag) which were modified for the American rail type RE115. These rail fasteners are applied to the solid slab track and meet increased requirements for vertical forces and lateral deformability.

The railway bridge is set to open in fall 2022. The client and operator is Signature on the Saint Laurent Group G.P (SSLG). The bridge was designed by T.Y.Lin International and built by SSLC (Signature on the Saint Lawrence Construction GC).

MAURER SE

MAURER SE