SIP®-A Bearings: First Two-Stage Seismic Protection Worldwide

The world’s first SIP®-A bearings were installed in a research institute in Mexico City to protect it against earthquakes. The bearings react in two stages in the event of an earthquake, and thus protect not only the structure but also the sensitive interior of the tall, narrow building. In addition, the innovative isolators saved considerable construction costs, as they facilitated building smaller foundations and a more slender load-bearing structure.

Media

Mexico City: The adaptive isolators protect patients and equipment

The National Institute of Medical Sciences and Nutrition in the south of Mexico City (Instituto Nacional de Ciencias Médicas y Nutrición Salvador Zubirán, INCMNSZ) is a medical teaching and research centre where patients are also admitted.

The INCMNSZ was designed by the architecture firm Arquinteg (Mexico City) in 2018/19: with 13 above-ground floors and an underground car park with four levels. Mexico City is located in a seismic area and, in light of the tall and narrow design, this resulted in relatively large tilting moments. “That is why the foundation engineers consulted us as experts for seismic protection as early as the planning stage,” reports Dr Luís Pinto, MAURER Regional Manager for Mexico.

It was clear that in the event of an earthquake, the compression and tensile loads would be so high that normal foundations did not suffice. However, correspondingly large foundations would have been too expensive. It was also too narrow on site for more extensive dredging, which would then be necessary.

Instead, building isolators were installed. When an earthquake acts horizontally on the building, they decouple the visible part of the building from the underground part, causing horizontal displacements within the isolators. This results in far smaller tilting moments, which are easy and economical to transmit.

MAURER’s early involvement in the planning process facilitated an innovative solution: “We normally use SIP®-D bearings in such a case”, reports Dr Pinto.

Isolating, dissipating, re-centring, stabilising

In the event of an earthquake, SIP® bearings generally assume four functions:

- They isolate the building from its foundations and allow horizontal movements in all directions.

- They limit movements through internal friction by converting kinetic energy into heat (dissipation).

- They re-centre the building in its original position following an earthquake, as they have concave sliding surfaces.

- They transmit vertical loads.

According to Dr Pinto, however, the special feature in the case of INCMNSZ was “that the accelerations should be kept as low as possible due to the patients and sensitive equipment.” Even in the event of an earthquake, the institute should be able to continue operation under all circumstances, patients should not be injured or equipment damaged by falling parts of the suspended ceilings. The FEMA (Federal Emergency Management Agency, US) guidelines specify a maximum acceleration of 0.3 g on each floor. This cannot be achieved with conventional SIP® bearings in view of the many floors.

At that time, MAURER already had the newly developed SIP®-A bearings (MAURER Adaptive Sliding Isolation Pendulum) in the pipeline: INCMNSZ in Mexico City was the ideal case of application. ‘A’ stands for “adaptive”, a bearing that adapts to the earthquake requirements.

Innovative step function

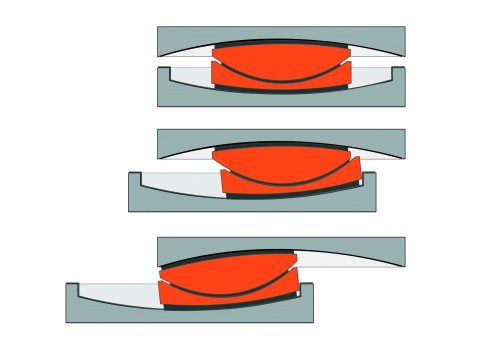

The basis for the SIP®-A is the Double Sliding Pendulum MAURER SIP®-D, which has been used since 2004. It has two (“D” for double) concave main sliding surfaces and one sliding lens (puck) and is equipped with the sliding material MSM® (= MAURER Sliding Material).

A new feature is that both sliding surfaces react differently. The bottom part of the bearing has a sliding surface with low friction. When an earthquake begins, or if it continues to be a normal earthquake, and therefore only quite small horizontal forces act, then the bottom bearing level alone isolates or moves.

If, however, the seismic forces increase, larger displacement within the isolators is also required. At this point, the second, upper sliding surface comes into play. This has a higher friction and thus also achieves a higher energy dissipation or braking effect. As a result, the movement of the building is more reduced and better controlled.

The upper sliding surface is only activated by relatively strong earthquakes. The step effect is primarily relevant for taller structures, since with conventional bearings, which can also dissipate large earthquake energies, the initial friction, that is the resistance, is quite high. Thus, there is an initial jolt in the moment when the friction is overcome. This jolt leads to ever greater and unacceptable accelerations upwards in the building with damage to its content and the structure.

SIP®-A reacts very gently without jolting even at a lower force application. The second stage is then activated during the movement. The effect of this is that the building does not move jerkily but sways gently, which reduces the acceleration below the permissible limit values even on the upper floors.

The adaptive Double Sliding Isolation Pendulums SIP®-A used in INCMNSZ have an effective pendulum radius of 600 mm. This controls the isolation period such that within the horizontal movement of up to ±300 mm in all directions, the horizontal acceleration drops below 0.3 g – even on the upper floors. A total of 34 bearings were installed with a service life of at least 50 years. They transmit vertical loads up to a maximum superimposed load of 10,900 kN.

Cost savings due to the isolators

The SIP®-A bearings saved a substantial amount of construction costs because only normal foundations were necessary. In addition, the load-bearing structure was optimised after it was clear which forces the seismic isolators accommodate. Initially, a steel structure with large composite columns was planned. Due to the reduced seismic loads, no concrete was required at the columns. A steel structure was enough.

The first SIP®-A bearings worldwide were built in Munich in 2020 and tested at EUCENTRE in Pavia (Italy). Installation took place from April to November 2021. The inauguration of INCMNSZ is scheduled for the second half of 2024.

Structure Types

- About this

data sheet - Product-ID

8042 - Published on:

29/08/2023 - Last updated on:

29/08/2023

MAURER SE

MAURER SE