Seismic Retrofitting of Viaduct Piers

Colombia: Horseshoe shape of the Yarumo Blanco Viaduct challenges engineers.

Media

Rugged mountains, high seismic risk and a half-finished viaduct shaped like a horseshoe – that was the situation in the Colombian Andes. After construction had stopped for years, the problem was solved with a technical masterpiece: The endangered viaduct piers were retrofitted with seismic isolation using sliding isolation pendulums. Therefore, they were sawn through at the bottom and lifted. The isolators have a very high coefficient of friction of 7%, which could only be achieved with MAURER isolators.

The crossing of the Andes (Cruce de la cordillera central) from Bogota to the west coast was already being planned in 1902. The large-scale project started around 2010; the most important while also the most complex viaduct was “Yarumo Blanco”, named after a legendary tree of the Andes. In 2015, construction stalled for years. There were also political reasons for this, but when the construction project was started again, one of the problems identified was that the half-finished viaduct did not comply with the seismic codes established in the meantime.

Short piers with seismic risk

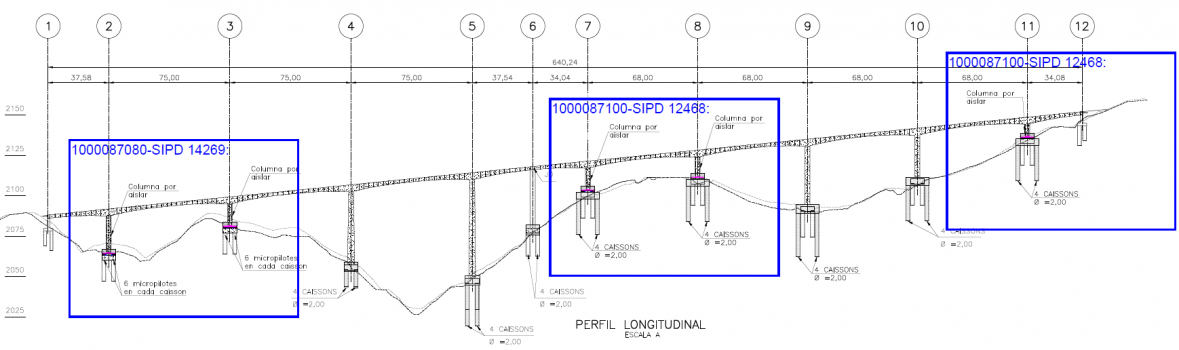

The approximately 640 m long viaduct stands in a rugged mountain jungle in the “Departamento del Quindío” and winds in the shape of a horseshoe around a rock with a 5% slope. Both the complex geometry and the high seismicity in the region required subsequent improvement of the viaduct.

Crucial point was the height difference of the 10 viaduct piers, ranging from 20 to 50 m. This difference in height leads to unequally stiffened piers, which overloads the lower piers (axes 2, 3, 7, 8 and 11) in the event of an earthquake. The horizontal seismic movements were estimated to be up to 600 mm in all directions.

Double sliding isolation pendulums isolate, dissipate, centre and transmit

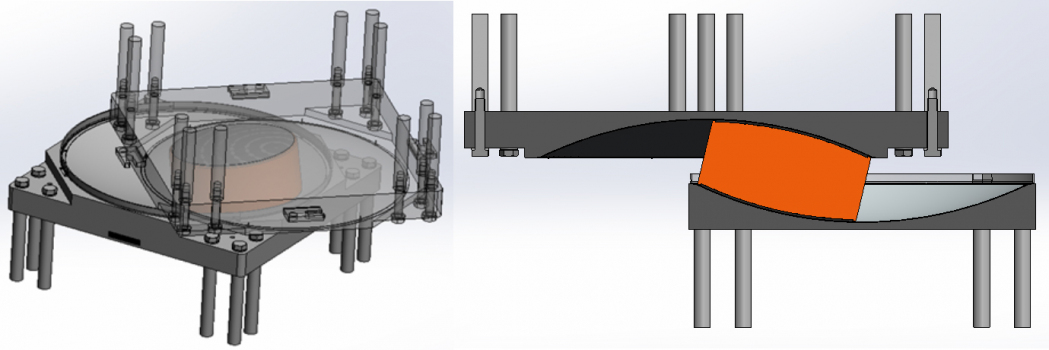

To prevent damage, these five piers were each isolated with four so-called SIP®-D-Bearings of MAURER. SIP® stands for Sliding Isolation Pendulum (Gleitpendellager). “D” (Double) indicates that the isolators have two concave surfaces (instead of one). The horizontal displacement is thus equally distributed over two surfaces. Therefore, SIP®-D-Bearings can be built smaller and lighter. This saves space, time and costs.

The SIP®-Bearings have four functions:

- They isolate the piers from their plinths and allow horizontal movement of up to ±600 mm in all directions.

- At the same time, they limit movements through a high internal friction of 7% by converting kinetic energy into heat (dissipation).

- They elastically re-centre the piers in their initial position following an earthquake.

- They transmit vertical loads of approximately 14 MN.

High coefficient of friction is decisive

Due to the high seismicity, a particularly high damping performance of the sliding isolation pendulums was required. Sebastian Patino, Technical Consultant for Seismic Protection Systems at MAURER, explains: “A necessary coefficient of friction of 7% was calculated. Only MAURER could guarantee this, thanks to the patented sliding material MSM®.” MAURER Sliding Material can be specifically calculated for defined coefficients of friction and provides further advantages over conventional Teflon (PTFE). The isolators can thus be built smaller and have at least a fivefold service life (50 years).

It was the first time that SIP®-D-Bearings with MSM® were installed in Colombia. “That’s why we actively participated in the conception, adaptation and constructive design of the isolators,” Patino reports. In addition, MAURER had to prove the performance of its isolators in tests carried out at the seismic test rig in EUCENTRE Pavia.

Retrofit installation under sawn-through piers

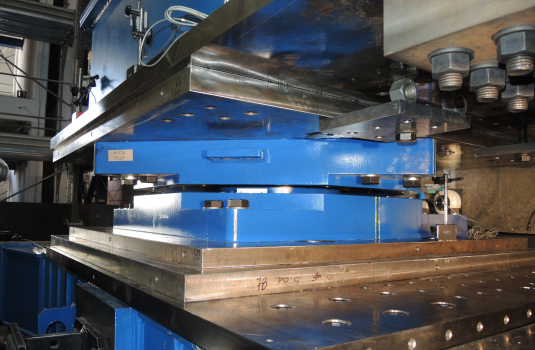

Normally, bearings are located on top of the piers, directly under the bridge deck. However, no isolators were planned on the piers, which had already been monolithically concreted. The subsequent installation of the isolators required decoupling of the bridge deck and piers, which could only be realised at the bottom of the piers due to the construction. Therefore, a spectacular installation took place in summer 2021: with sawing through, lifting, inserting the isolators and lowering. Details:

- The rectangular pier is strengthened with a cuboid concrete structure just above the plinth. In the process, the plinth and cube are already provided with recesses for fixing the anchoring plates.

- 8 supporting structures around the cube hold the pier in position with hydraulic flat jacks.

- A diamond wire saw cuts through the pier horizontally.

- 4 hydraulic flat jacks placed under the cube lift up the pier by approximately half a meter.

- 4 SIP®-D-Bearings are inserted and anchored. They are approximately 1 m high including screw dowels and measure 1.8 x 1.3 m.

- Slow lowering of the piers onto the isolators.

A video of the National Street Institute (Instituto Nacional de Vias) shows the action:

The viaduct was opened by President Iván Duque Márquez on 24/11/21.

References

Structure Types

- About this

data sheet - Product-ID

8024 - Published on:

17/03/2022 - Last updated on:

17/03/2022

MAURER SE

MAURER SE