Rehabilitation of Sengbach Dam, Solingen

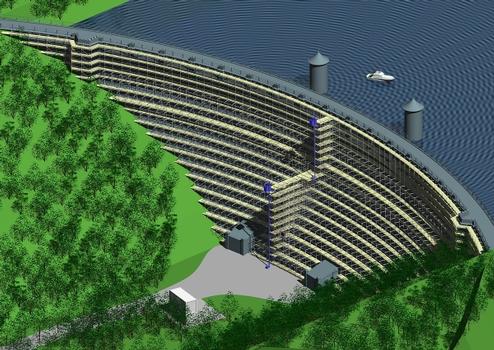

The Solingen municipal utility invited tenders for the refurbishment of the wall air side of the Sengbach Dam. This required a scaffold structure that had to meet geometrically demanding conditions for scaffolding the dam wall: extreme dam wall curvature, extension/length of the dam wall 185 m, height 43 m, required scaffold area including the platform steps and the material approach scaffolds over 5,000 m².

Furthermore, the special requirements for the scaffold anchorage as well as the insufficiently load-bearing, backfilled scaffold erection base are to be observed. The following work is to be carried out from the scaffold structure: Chiseling out and renewal of the entire joint mortar, replacement of defective masonry units (approx. 25% of the masonry units).

Teupe & Söhne Gerüstbau GmbH from Stadtlohn developed a scaffold construction from steel tube coupling material during the tendering phase with intensive calculation including detailed work preparation, which was able to ensure absolutely continuous stepless scaffold decking with completely different geometric conditions of the scaffold surfaces from scaffold day to scaffold day. Thus, in addition to a trip-free scaffold deck, easy handling of the extensive transverse transport of demolition and installation materials was possible for the scaffold user in the scaffold. Through the skilful use of the steel tube coupling scaffold material, TEUPE guaranteed optimal adaptation of all scaffold working levels to the dam.

The scaffold anchorage of the approx. 180 t heavy scaffold structure was planned with special anchors, which were embedded 0.80 m deep into the structure down to the load-bearing subsoil.

TEUPE was awarded the contract for the work and erected the scaffold structure in accordance with quality standards and on schedule. The structural analysis and the working drawings in 2-D and in 3-D were prepared in-house by TEUPE. 25 km of scaffold tubes were installed, for which approx. 22,000 scaffold couplers were required. The scaffold anchorages were checked for their permissible use by means of an anchor test construction specially manufactured for the project. As many as 1,300 scaffold anchors were installed.

According to the companies involved in the refurbishment project, the site supervisors and the client, the scaffold design conceived during the tendering phase and executed after the contract was awarded has proved very successful and has created a safe, high-quality working basis at all times for all those involved in the construction.

References

Structure Types

Relevant Websites

- About this

data sheet - Product-ID

7027 - Published on:

08/11/2013 - Last updated on:

03/03/2023

Teupe & Söhne Gerüstbau GmbH

Teupe & Söhne Gerüstbau GmbH