POLYFLEX®SLIM-PU – Expansion joint for building application

POLYFLEX®SLIM PU represents a reliable alternative when it comes to the requirement of flexible and watertight passages. An optimal water tightness is already guaranteed at a material thickness of 40 mm only. Particularly characterizing is its slim design. The joint hence does not require any cover plate.

Media

Principle

The POLYFLEX®SLIM PU plug expansion joint achieves a completely new standard in terms of quality and working life for applications in buildings. Thanks to the new Polyurethane (PU) flexible material, that has been developed in cooperation with renowned companies of the chemical industry, as well as our special joint design, we have successfully developed a reliable plug expansion joint for the specific requirements of buildings.

Reduced volume for slim design

POLYFLEX®SLIM PU represents a reliable alternative when it comes to the requirement of flexible and watertight passages. An optimal water tightness is already guaranteed at a material thickness of 40 mm only. Particularly characterizing is its slim design. The joint hence does not require any cover plate.

Advantages & characteristics

Material assets:

- The avoidance of mechanical wear parts results in an exceptional high working life and non-ageing durability

- The joint guarantees thorough water tightness through the use of the new PU material

- Free of germs and fungus hence enabling proper resistance to environmental influences and chemicals such as alkaline, acids, chlorides

Application assets:

- No additional noise thanks to jointless ground level

- No sound transmission to adjacent construction components

- Super-fast installation with resilience after a few hours

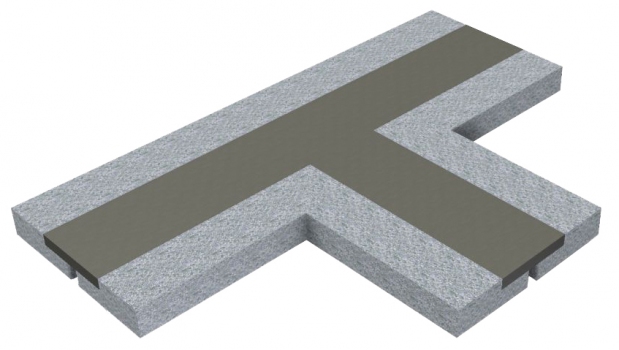

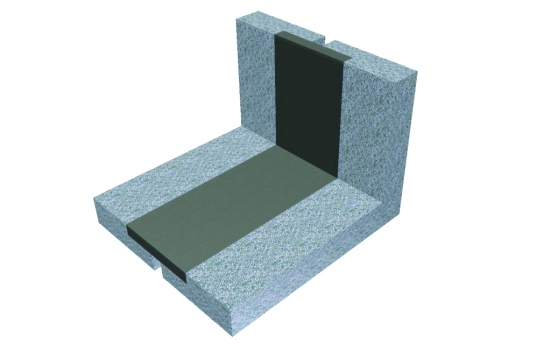

- Design for T- or X-crossing in any shape or angle as well as vertical format possible

- Available in grey or black as standard or additional colors upon request

Scope of application

- Car park and parking decks

- Railway stations and platforms

- Airport buildings and hangers

- Pharmaceutical and chemical industry

- Clinics, hospitals and laboratories

- Food processing industry

- Sliding floors in heavy load industry

- New construction and refurbishments

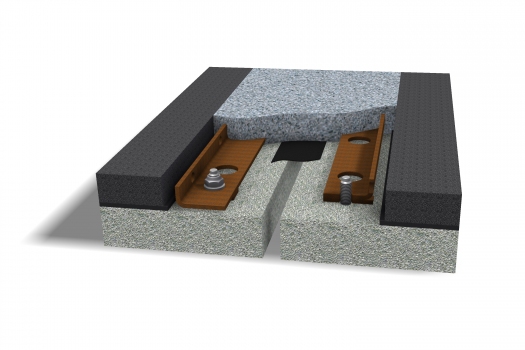

Construction principles

The POLYFLEX® filling material features excellent adhesion to the supporting structure and the adjacent surfacing and is therefore capable of safely transferring horizontal loads to the structure. Additionally, perforated steel angles, which are fully embedded within the joint material, are bolted to the structure and can transfer even the highest loads (e. g. from heavy vehicles braking on the joint at downward slopes). These steel angles also support the adjacent surfacing so as to prevent the asphalt from being depressed into the sides of the joint material.

Material description

- Elastic, solvent-free grout system

- 2-component mixture

- Verified, constant mixing proportion ensures easy handling; mixing errors are therefore almost certainly excluded

- Cold material processing for more flexible storage and installation

- A polymer concrete for the supporting structure is recommended

- Both materials are optimally coordinated with relation to processability and strain

Quality and certification

Since July 2012 mageba owns the European Technical Approval ETA-12/0260 for the installation of POLYFLEX® in bridge structures. The mageba system for application in buildings was developed on the basis of ETAG 032 (European Approval for expansion joints in bridges). A valid ISO 9001 certification, 100 % factory production control and continuous third party quality control of the Polyurethan material by the German governmental body, the Material Testing Institute of the University of Stuttgart (MPA) ensure both the high-quality level of products and manufacturing facilities.

References

- About this

data sheet - Product-ID

7464 - Published on:

25/01/2017 - Last updated on:

17/11/2021

mageba group

mageba group