No smooth bridge construction without a suitable scaffolding erector

Specialist Gemeinhardt Service responds quickly and reliably when erecting the protective scaffolding for the Siligmüller Bridge in Würzburg.

As Reinhard Mey already sang in the 70s: "No, with three'n is already one too many". Züblin site manager Thomas Rösch and Ingolf Stuber, project manager at Gemeinhardt Service, felt the same way. The Saxon special scaffolding erector placed the protective scaffolding over two railroad tracks so that the construction company could safely rebuild the Siligmüller Bridge in Würzburg by October 2022.

In 1995, already closed to road traffic after 26 years, it was finally demolished at the turn of the year 2008/09. Even then, Gemeinhardt had provided the scaffolding - but for another construction company. That's why Züblin and Rösch had little doubt that the Saxons would be awarded the contract again. The 49-year-old: "They were more expensive than other bidders, but they know the situation around the bridge and as Züblin, we trust the company to carry out this work." In addition, Stuber assured that no additional foundation is needed for the protective scaffolding: the 30-centimeter-thick concrete foundation should be sufficient.

However, when it comes to construction, the test structural engineer comes into play. Of several test holes in the foundation, a few were no good. "From our point of view, it was safe," Rösch and Stuber agree. The inspector insisted on his view of things: A new foundation was needed. Annoying for Züblin because additional costs were incurred. Annoying for Gemeinhardt because, on the one hand, the scaffolding erectors including materials were already on their way from Roßwein to Würzburg, and on the other hand because this meant that an entire work phase was cancelled and the operation had to be completely rescheduled.

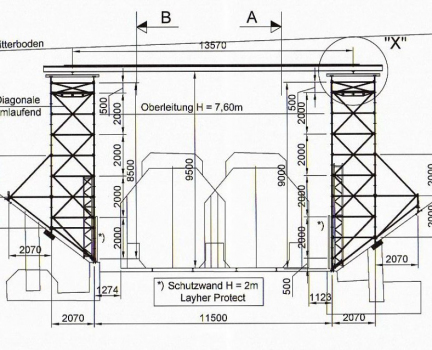

"Deutsche Bahn gave us four five-hour stoppages each night. There's not a minute longer," says scaffolding master Stuber, because ICE and freight traffic as well as the city railroad run over the route under the future bridge. Because one closure was cancelled, the 42-year-old had to reschedule the operation within a week: Instead of using a construction crane from one side of the tracks, two construction cranes were used from both sides, and instead of eleven men, 16 were on the construction site. The scaffolding crews arrived on a long weekend with four semitrailer trucks, each carrying 18 tons of material, and nine HEB steel girders, each weighing ten tons. The 16-meter-long girders were lifted over the overhead lines with filigree, creating a "lid" over which Züblin could then rebuild the bridge within two years. 45 meters long and just under 14 meters wide, it connects the old town and the Frauenland district, and around 11,000 vehicles are expected to cross it daily from the beginning of 2023.

The dismantling of the protective scaffolding in October worked smoothly - within two nightly closure breaks, the scaffolding was dismantled and loaded onto the semitrailer trucks. Because the construction company also had to move a lot of material from the track area during the same, traffic-free period, the two partners helped each other with cranes and labor. "The removal worked out well," says Thomas Rösch, summing up the cooperation, "the fact that the inspector did not consider the foundation to be load-bearing cannot be blamed on Gemeinhardt Service."

"Anything that is complex or has to be done quickly is our thing," says Ingolf Stuber. Since the flood of the century in 2002, the Saxons have had a particular soft spot for bridges - because back then many traffic routes also suffered major damage. The requirements in bridge refurbishment are diverse and need special know-how and material: As a rule, the scaffolders have to deal with two traffic routes at the same time. If a road or river runs under the bridge, even the smallest parts must not be allowed to fall off during the refurbishment. In addition, it is difficult to erect scaffolding up to a height of 50 meters, so the workmen need lightweight suspended scaffolds. But architects 50 or 100 years ago never thought of fixing scaffolds in place. That's why Gemeinhardt always has to come up with something new. And of course, the time factor always plays a special role during assembly and dismantling.

"We need highly qualified employees in order to set ourselves apart from competitors through quality of work on the one hand and to compensate for higher costs through speed on the other," says Stuber, because it is not quality that counts, especially in public tenders, but price alone. Every year, the special scaffold erector invests more than 100,000 euros in further training for its current 42 employees. All 17 scaffolders are trained, ten even as state-certified scaffold erection crew leaders and two as master craftsmen. While many scaffolders complain about the increasing requirements for operational safety, such as TRBS 2121, Stuber sees this as an opportunity to further set himself apart from other scaffolders. Particularly when it comes to occupational safety, he makes no compromises: "After all, it is our responsibility as entrepreneurs to protect our employees and those of our customers as well as possible."

Jens Gieseler

References

Structure Types

- About this

data sheet - Product-ID

8034 - Published on:

17/01/2023 - Last updated on:

17/01/2023