Innovative Gridshell

Atrium roof as gridshell with patented node solution for light-flooded research building in Basel - planned by formTL Ingenieure and realized by RUCH Metallbau.

Media

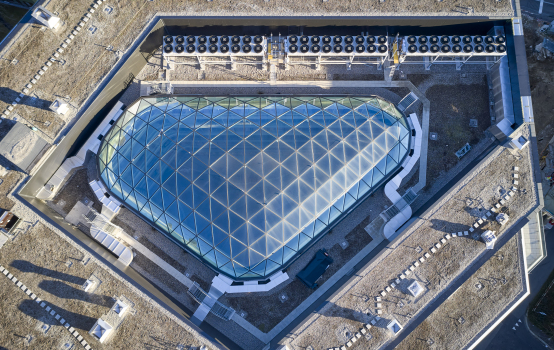

A new laboratory and research building for ETH Zurich has been completed on the Schällimätteli Campus in the immediate vicinity of Basel University Hospital. The atrium building D-BSSE (Department for Biosystems Science and Engineering) is characterized by formal clarity and spatial permeability - because the concern of Nickl & Partner Architekten was to reflect the interdisciplinary academic exchange also in the architectural design. A high degree of transparency characterizes the appearance from the outside. In addition, the architects placed a light-flooded atrium in the center of the fully glazed, pentagonal building, which is intended to support communication among the research teams with its high quality of stay. In plan, the atrium forms an irregular triangular shape and is spanned at the top by a graphic-looking glazed lattice shell. It protects the atrium from wind and weather and gives the space an atmospheric effect. The engineers at formTL were responsible for the erection planning of the innovative net structure - in close cooperation with the metal construction company carrying out the work, RUCH Metallbau AG from Altdorf.

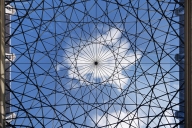

The curved, column-free glass roof structure consists of a single-layer dome shell about 20 meters wide and 35 meters long. Ist rungs of hollow steel sections cross each other in such a way as to create a triangular grid. This construction method gives the glass roof ist characteristic appearance. The basis for the glass roof is a horizontal compression ring made of steel tubes, which draws a free form in the ground plan. The individual elements of the grid structure, which are prefabricated in the factory, are mounted and welded onto this. The heart of the lattice shell is a special node solution that was specially developed by formTL and RUCH Metallbau for the project. This patented face node design made it possible to optimize the entire fabrication and assembly process and to realize the atrium roof without a secondary structure for the glazing. Proof of the glazing's 60-hour residual load-bearing capacity was provided with a 1:1 scale mockup.

formTL took over the 3D model and coordinated planning, workshop, and assembly planning as well as the structural analysis for the atrium roofing. This ensured end-to-end data transfer from the design to the CNC system in the factory. Thanks to the optimally coordinated work processes, the new atrium roof for the Basel research building could be planned precisely in teamwork by formTL and RUCH Metallbau and realized in high quality.

.

References

Structure Types

- About this

data sheet - Product-ID

8022 - Published on:

04/02/2022 - Last updated on:

04/02/2022