First Time Installation of Spherical Segment Bearings in Barsinghausen

The replacement of roller bearings is a reoccurring necessity: now however, for a first time the maintenance section of the headquarters of DB Netz AG entrusted Maurer Söhne to retrofit for a first time so called spherical segment bearings. Since 2013 this type of bearings, which is a variation of the well proven spherical bearings, enjoys a European Technical Approval ETA06-131.

Media

In order not to compound this first installation with difficult site conditions, a standard bridge was selected as a pilot project.

Roller Bearings plus Rotational Capacity

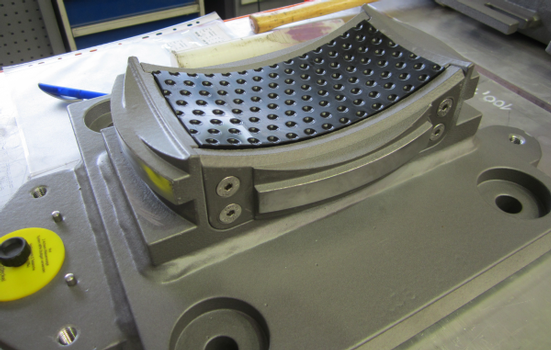

Special feature of the new spherical segment bearings is the fact that they adopt the given rectangular area which the roller bearings do. This enables an exactly same load transfer into the adjacent structural members, such that there are no complicated and expensive modifications necessary as it would be the case with standard bearings. Moreover, these spherical segment bearings display a rotational capacity along all the 3 spatial axes, while roller bearings are not capable to rotate around the longitudinal axis of the structure. These new bearings were checked and released for use in the factory in Munich by German Railways.

In the night from May 17 to 18 near to Barsinghausen the first two unidirectional movable double spherical segment bearings were installed.

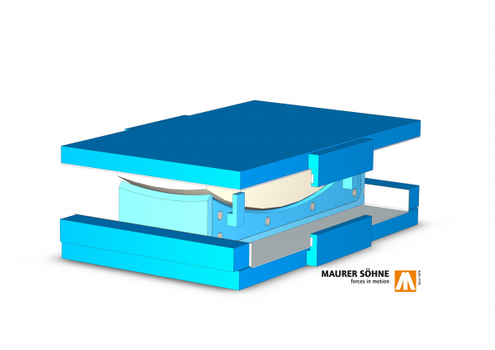

Exactly a week later this installation was followed by two fixed bearings. All four bearings display a dimension of 500 x 300 x 280 mm and a weight of each ca. 250 kg, catering for a vertical load of ca. 2,100 kN.

Night Sprint

Albeit the replacement of the bearings was not exactly a technical challenge, the ambition of this task was to carry out the replacement within 5:45 hours, while the railway was closed from midnight on. On site, Maurer staff based in Lünen did the replacement.

Background of spherical segment bearings

Spherical segment bearings display of a rectangular base and of a rotational capacity around all 3 spatial axes. The challenge in the design of such a spherical segment bearing was to find the right location where to cut the spherical segment such that finally a bearing with a rectangular base could be received.

To be more concrete, for two questions a single technical answer had to be found: how do we keep the curvature of the calotte low or flat enough that the stress distributes equally? And how remains the curvature of the calotte high or round enough that this segment does not slip out? Further, this new bearings displays of a stopper such that the spherical segment cannot move out.

Difficult was also the insertion of the sliding material MSM® and its chambering: the rectangular base section causes in the calotte segment a complicated geometry, because it is curved in all directions. The European Technical Approval ETA-06/0131 proves that Maurer has mastered these challenges.

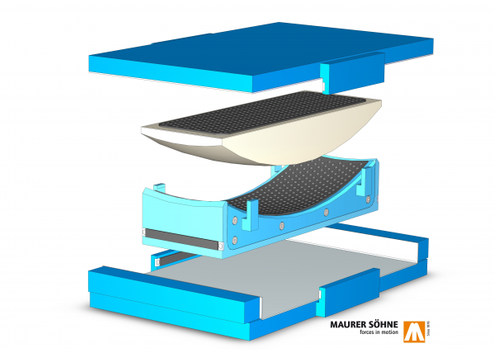

Splitting the displacement by way of doubling

A further feature of the old roller bearings is the fact that they split the horizontal displacement above and below into equal parts. This splitting can also be achieved by the new double spherical segment bearings. Like in a sandwich the segment bearings "floats" between two sliding surfaces above and below. Lateral stoppers guide the horizontal movements.

Structure Types

- About this

data sheet - Product-ID

7188 - Published on:

18/09/2014 - Last updated on:

19/05/2017

MAURER SE

MAURER SE