Colossus of the Caribbean with challenging load changes

MAURER supplies all bridge bearings for the Pumarejo cable-stayed bridge in Colombia, the longest road bridge in the country. Challenges are strong vertical and horizontal bridge deck movements under wind and earthquake effects.

Media

MAURER provides all bridge bearings for the Pumarejo cable-stayed bridge in Colombia

The Pumarejo cable-stayed bridge near Barranquilla is the longest road bridge in Colombia. The challenges are strong vertical and horizontal bridge deck movements induced by wind and earthquakes. MAURER developed and supplied all bearings needed for this purpose as well as the bearings of the foreland bridges in close coordination with the building owner.

In colloquial speech, the “Puente Alberto Pumarejo” is called “El coloso del caribe”, The colossus of the Caribbean. With 38.10 m, it is the widest bridge in South America, and with a length of 3.2 km one of the longest bridges in Colombia. The six-lane Pumarejo bridge with lateral bikeways and pedestrian ways crosses the Río Magdalena near Barranquilla and connects the city with the northeastern Caribbean coast. The new bridge is not only vital for road traffic but also for maritime traffic. It replaces the predecessor bridge “Puente Laureano Gómez” with a vertical clearance of just 16 m, which is – at least partly – to be demolished. The vertical clearance of the new cable-stayed bridge is 45 m, the main span width is 380 m.

Alternating compressive and tensile forces

Challenging wind and seismic load cases require sophisticated measures in the load-bearing structure, this being the reason that a total of ten bridge bearings were installed between the bridge deck and the two pylons P13 and P14. The largest ones of these bridge bearings serve for transferring compressive forces of up to 45,000 kN. However, the plumb-vertical load acting on the structure was not the only challenge: earthquakes can also cause tensile forces of up to 15,000 kN.

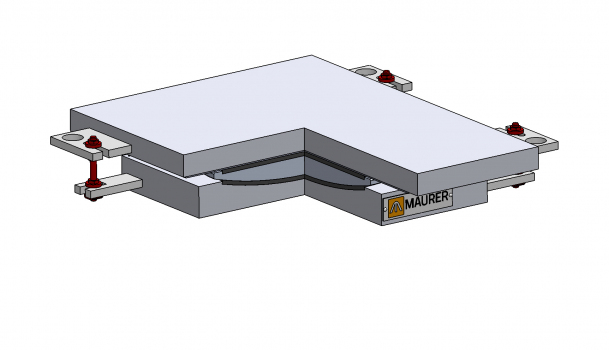

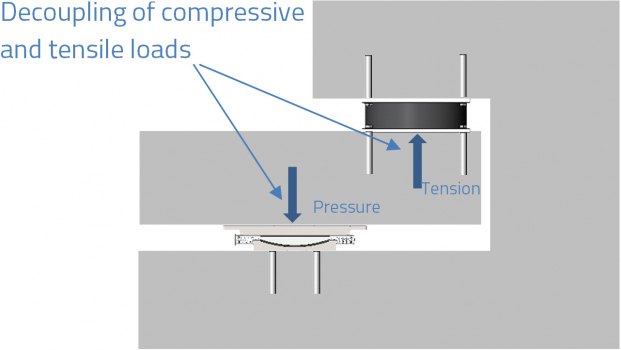

The planning team solved this problem by installing two bearings placed on top of each other (see picture), with two pairs of bearings per pylon. MAURER developed suitable bearings in close coordination with the planners:

- at the bottom: MSM® spherical bearings for the structural load,

- at the top: elastomeric bearings for the tensile forces.

Thus, compressive and tensile loads were decoupled.

The concrete bottom chord of the bridge deck with a thickness of about 120 cm that activates the bearings depending on the direction of force is situated between the two bearings. A concrete support above the upper bearings transfers the tensile forces into the pylon.

“The client – SACYR – contacted us in order to find a solution for the challenges around the pylon axis in close coordination with the company. The problem: in case of load changes, a vertical clearance must be overcome without damaging the bearings or restricting their usability,” explains Dipl.-Ing. Peter Günther, Technical Sales Director, MAURER SPS GmbH. Since lifting forces relate to rarely occurring load cases, this applies in particular to the bearing located at the top. “We were able to present a solution based on our experience from other product ranges: a special mounting method for the MSM® – MAURER Sliding Material – that prevents damage or wear.”

Statement on the bearings

Spherical bearings enable rotations around all axes. MSM® is the patented high-performance material on all sliding surfaces. It can accommodate strong forces and rotations with low friction. Due to the location close to the sea, the calottes were made of corrosion-free MSA® (MAURER Sliding Alloy).

MAURER Elastomeric Bearings are steel-reinforced elastomeric bearings made of chloroprene rubber.

Seismic-proof cable-stayed bridge

Another special feature of the Pumarejo Bridge is its resistance to earthquakes. The pylons were designed for accommodating very high seismic forces. For this reason, structural bearings that transfer horizontal loads were vertically installed at the four sides of the pylon.

The forces in the longitudinal direction are accommodated by two large MSM® Spherical Bearings each. The forces result from traffic, wind, temperature, and earthquakes, with the latter presenting the highest loads. This is why the MSM® Spherical Bearings for the longitudinal forces are designed for an MCE (Maximum Considered Earthquake) with a longitudinal force of up to 65,000 kN.

The horizontal forces in the transverse direction of up to 35,000 kN are accommodated by four elastomeric bearings each.

Successful cooperation

MAURER supplied the bearings for the entire bridge, including foreland bridges and ramps ‒ a total of 83 spherical and elastomeric bearings in a variety of designs. The largest ones feature dimensions of up to 150 x 150 cm and a weight of 5.5 t. They were installed by 2019.

A complex structural protection system like this can only be successfully completed if all stakeholders engage in trustful and professional cooperation. Therefore, we like to express our gratitude towards the building owner INVIAS (the national Colombian road construction institute), the prime contractor SACYR, as well as the engineering offices CFCSL (Carlos Fernandez Casado SL). The official inauguration of the bridge took place on December 20, 2019.

References

Structure Types

- About this

data sheet - Product-ID

8013 - Published on:

08/12/2021 - Last updated on:

08/12/2021

MAURER SE

MAURER SE