Award-Winning Seismic Protection in El Salvador

During a building conversion, diagonal steel struts with hydraulic dampers were installed for the first time in El Salvador. The MHDs (MAURER Hydraulic Damper) will prevent earthquake damage in the future and protect not only the building structure but also the equipment and furnishings. The innovative seismic protection retrofit was awarded a prize.

Media

Building dating from the 1970s retrofitted with hydraulic dampers

The Edificio Napoleon Bolaños Melendez located in San Salvador, the capital of El Salvador, is the first building in the country with seismic damping. It was built as a three-storey reinforced concrete structure in the 1970s. FEDECREDITO, a regional bank, wanted to house its main data centre in this building. An upgrade to the seismic protection was called for as part of the renovation, since the building had suffered moderate damage during the last two earthquakes in 1986 and 2001.

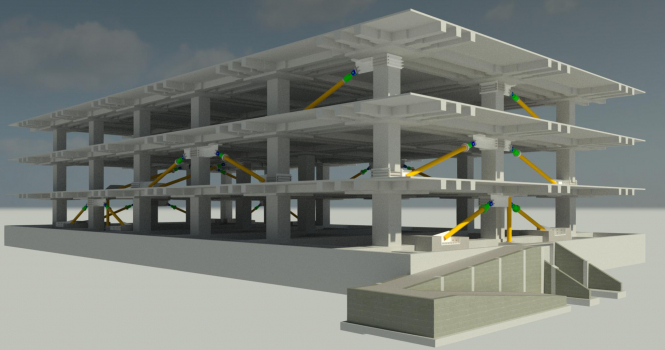

The bank building’s main structure consists of concrete waffle slabs with reinforced concrete beams joining the main columns which function as earthquake-resistant frames. Originally, the plan was to install buckling restrained braces (BRBs) in selected bays in order to stiffen and strengthen the building. However, procuring and importing the elements proved to be problematic, so the engineering firm NARVAEZ HINDS was commissioned to review the planned retrofit scheme and identify alternatives to assure equivalent or better seismic protection.

Following the analysis, NARVAEZ HINDS concluded "that a system with steel pipe diagonals with hydraulic MAURER dampers with a capacity of 100 to 200 tonnes would actually be a much better option," reports company director Ricardo Narvaez. "This is because the MHDs would not only reduce the force demands on the existing building, but also dramatically reduce the accelerations to which expensive data equipment in the building would be exposed." This, in turn, will reduce or even completely eliminate downtime after the next strong earthquake.

Hydraulic dampers prevent earthquake damage

MAURER Hydraulic Dampers for seismic protection dissipate energy by converting kinetic energy into heat in a highly efficient way. They differ from conventional linear viscous dampers in that their force development is degressive with increasing earthquake intensity, in other words: the faster the movements, the less the damper resistance increases. This results in optimum damping and prevents design limits for forces and accelerations from being exceeded.

In the event of an earthquake, a special mechanical fluid flow system within the dampers allows relative movements of up to ±60 mm and controls or limits the response force at a certain level. The damping exponent is 0.2, which results in a smoother response while still generating sufficiently high forces for medium to strong earthquakes. This limits movements to a minimum and prevents structural damage.

On the outer shell of the building directly behind the façade

According to Eng. Ricardo Narvaez, the greatest planning challenges in San Salvador were "the exact positioning of the damper diagonals and the connection to the existing building structure". The solution: steel struts located directly behind the façade, into which the dampers were integrated, are connected to the building's main seismic resisting frames at both ends using external high-strength steel rods and anchors. This is cost-effective and still ensures the desired function.

A total of 20 MHDs were installed in the perimeter frame, except where the data centre equipment required another location. On the two lower floors, there are two dampers (one per bay) in each of the four sides of the building, while on the upper floor there is one damper for each direction. "With this scheme, we can retain the seismic displacements between the floors, which statistically occur once every 1,000 years during stronger earthquakes, just within the elastic range. This prevents damaging cracks in the building, even for very strong earthquakes, and provides the optimum protection for people and equipment," reports Ricardo Narvaez. "For the more frequent earthquakes, which occur once every 250 years, we have achieved a completely elastic behaviour of the structure with no expected structural damage."

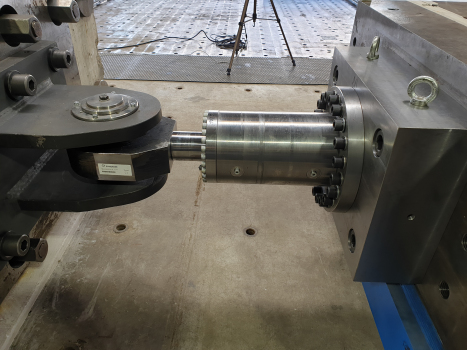

The dampers are up to 1.3 m long, with a diameter of 370 to 480 mm and a weight of 160 to 344 kg (without the diagonal struts provided by the client). Scheduled maintenance is not required for the dampers provided the loads do not exceed the design limits by more than the safety margin of 20%.

Successful tests and award

The 20 hydraulic dampers ordered (8 x MHD 2,000 kN; 4 x MHD 1,500 kN; 8 x MHD 1,000 kN) were produced by MAURER in Munich. In 2021, one of each damper type was tested for functionality at EUCENTRE in Pavia at speeds of up to 350 mm/s. Particularly owing to the special triple sealing system used, no leaks were detected following the tests. In addition, a very good response behaviour was verified; the damper restrains the structural movements very well after only 1 to 2 mm of movement.

All tests were carried out successfully according to the applicable European standards. Installation took place in early 2022 and the building was occupied by the end of 2022. After completion, the project was awarded first place in the PREMIO OPAMSS 2022. OPAMSS is the authority responsible for urban planning and building permits in the metropolitan area surrounding and including the capital city San Salvador. The prize was awarded for the use of innovative technology in the retrofitting of an old building and strict compliance with all applicable standards.

References

Structure Types

- About this

data sheet - Product-ID

8046 - Published on:

12/01/2024 - Last updated on:

12/01/2024

MAURER SE

MAURER SE