General Information

Project Type

| Structure: |

Deck arch bridge |

|---|---|

| Function / usage: |

Railroad (railway) bridge |

| Material: |

Steel bridge Structurae Plus/Pro - Subscribe Now! |

Location

| Location: |

Jammu and Kashmir, India |

|---|---|

| Coordinates: | 33° 9' 3" N 74° 52' 59" E |

Technical Information

Dimensions

| total length | 1 315 m | |

| arch span | 480 m |

Materials

| piers |

reinforced concrete

|

|---|---|

| arch |

steel

|

| abutments |

reinforced concrete

|

Case Studies and Applied Products

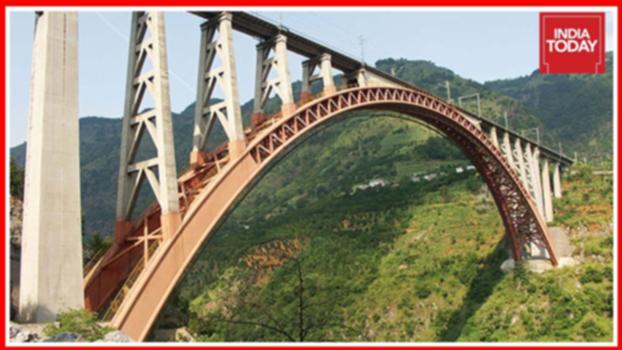

Chenab Bridge in India will be the world’s highest railway bridge

Traveling around the mountainous region of Jammu and Kashmir in northern India has always been difficult. In order to considerably shorten travel times, the Indian Government decided to build a new, 345 km l ... [more]

RESTON®SPHERICAL – Spherical bearings

mageba spherical Bearings are especially suited for bridges with big torsions and bridges located in very cold areas (temperatures lower than -30°C).

[more]Excerpt from Wikipedia

The Chenab Rail Bridge is an Indian railway steel and concrete arch bridge between Bakkal and Kauri in the Reasi district of Jammu and Kashmir, India. When completed, the bridge will span the Chenab River at a height of 359 m (1,178 ft) above the river, making it the world's highest rail bridge. In November 2017 the base supports were declared completed allowing for the start of the construction of the main arch.

In April 2021 the Chenab Rail Bridge's arch was completed and it is expected to open to rail traffic in December 2022.

Key technical data of the bridge include:

- Deck height (height above river bed): 359 m (1,178 ft), (height above river surface): 322 m (1,056 ft)

- Bridge length: 1,315 m (4,314 ft), including the 650 m (2,130 ft) long viaduct on the northern side

- Arch span: 467 m (1,532 ft)

- Arch length: 480 m (1,570 ft)

This makes the Chenab Rail Bridge:

- The world's highest railway bridge

- The bridge with the longest span in the 5 ft 6 in (1,676 mm) broad gauge railway network

Introduction and topography

Northern Railway has undertaken the mega-project of constructing a new railway line across the Indian union territory of Jammu and Kashmir between the towns of Udhampur near Jammu and Baramulla on the northwestern edge of the Kashmir Valley. This project was declared a national project in 2002. It is directed by the Northern Railway.

The extraordinary challenge lies in a large number of tunnels (totalling 63 km in length) and bridges (7.5 km) to be implemented in highly rugged and mountainous terrain, with the difficult Himalayan geology. The most difficult part is believed to be the crossing of the deep gorge of the Chenab River, near Salal Hydro Power Dam, by the Chenab Bridge.

Another, smaller, arch bridge proposed on the new railway line was the 657 m (2,156 ft) long, 189 m (620 ft) high Anji Khad Bridge between Katra and Reasi over the Chenab river tributary river. This proposal was abandoned by the railway due to the specific geology of the location and a cable-stayed bridge is proposed which will be Indian Railways first cable stayed bridge

Design

After many deliberations, taking into account aesthetics, economy, and availability of local expertise and construction materials, the Chenab Rail Bridge was designed as a large span single arch steel bridge with approach viaducts on either side. The arch is two-ribbed, fabricated from large steel trusses. The chords of the trusses are sealed steel boxes, internally stiffened and filled with concrete to assist in controlling wind-induced forces on the bridge. Another advantage of concrete filling is that internal painting will not be required.

The number of bearings has been minimized, particularly on the approach viaduct, through the use of continuous construction. This is advantageous, as it reduces the maintenance and inspection efforts, and improves the riding quality. The viaduct piers are of concrete, while the piers near the arch are Indian construction standards such as the Indian Railway Standards (IRS), the Indian Road Congress (IRC) and the Indian Standards (IS) were found inadequate for the large spans of the Chenab Bridge. For example, the Indian Railway Standards (IRS) is primarily intended for simply supported bridges with spans up to 100m (although these have been successfully used for higher spans up to 154m). The spans for the Chenab Rail Bridge greatly exceed this limit, and are continuous. Therefore, to assure a safe design, Indian national standards have been supplemented with International standards such as British Standards (BS), International Union of Railways (UIC) and Euro. Also, many global experts with versatile and relevant experience, have been involved in order to facilitate making the project a success.

Following are some of the design considerations taken into account:

- Limit state philosophy of design has been decided to be followed as per BS codes

- Computation of wind load effects as per wind tunnel tests

- Site specific seismic spectra developed by Indian Institute of Technology (IIT) Roorkee

- Provision of Euro code 8 for ductility detailing of very tall and hollow rectangular RCC piers

- Provision of long welded rail (LWR) over the bridges and resulting force calculation as per UIC – 774-3R guidelines

- Blast resistant design used

- Design checking for fatigue as per BS codes

- Deformation limits as per comfort criteria of UIC – 776-2R and UIC 776 -3R guidelines

- Redundancy provided in the structures, for lower level of operation during mishaps and against collapse in extreme cases of one pier failure

The Quality aspect has been emphasised, as the quantum of fabrication and welding is colossal. Mostly indigenous material compliant to IS codes has been planned to be used, whereas for the design, international codes have been referred, which means the Quality Control work is still difficult.

Construction

The Chenab Rail Bridge was originally intended to be completed in December 2009. However, in September 2008 the project was halted due to fears over the bridge's stability and safety.

Work on the bridge restarted in 2010 with the plan to complete it in 2015.

The design and construction was awarded to Afcons Infrastructure, a part of the Shapoorji Pallonji Group, the third-largest construction group in India with the help of IISc Bangalore. Major construction decisions were taken by Konkan Railway Corporation.DRDO helped in designing it as a blast proof by using special steel.

The erection scheme for the bridge is a project in itself. Two pylons (about 130 m and 100 m high) were erected on either side of the river, and two auxiliary self-propelled cable cranes (capacity of 20t each) were used to tow temporary auxiliary ropes across these pylons. The ropes were used to support the partly finished arch parts. After arch completion, the trusses will be added, finally the girder will be constructed as a horizontal sliding type platform.

- Jul 2017: construction work resumes.

- Nov 2017:The Work Arch Bridge To Completed By "May 2019".

- Nov 2018: Bridge under active construction.

- Dec 2018: Project may not complete by end of 2019.

- Aug 2019: 80% work completed. To be opened in mid of 2020.

- Nov 2019: 83% work completed. To be opened in March 2021.

- Jan 2020: To be opened in December 2021.

- April 2021: Both the end of the arch touched and closed on 5 April 2021. To be opened in 2022.

Maintenance

Regular painting of large bridges is an intimidating task; hence, a painting scheme was developed, having renewal of over 15 years, compared to approx. 5 to 7 years in most other Indian railway bridges.

Text imported from Wikipedia article "Chenab Rail Bridge" and modified on February 21, 2022 according to the CC-BY-SA 4.0 International license.

Participants

Relevant Web Sites

Relevant Publications

- (2017): Bridges. A History of the World's Most Spectacular Spans. 2nd edition, Black Dog & Leventhal, New York (USA), ISBN 978-0316507943, pp. 152-153.

- (2012): Conceptual Design of the Chenab Bridge in India. In: Procedia Engineering, v. 40 ( 2012), pp. 189-194.

- (2022): Fertigung und Montage der Chenab Railway Bridge in Indien. Presented at: 31. Dresdner Brückenbausymposium, 7./8. Juni 2022, Dresden (Germany), pp. 191-204.

- India builds major rail link. In: Bridge Update, n. 52 (June 2005), pp. 2.

- About this

data sheet - Structure-ID

20013811 - Published on:

14/10/2004 - Last updated on:

05/02/2019