LASTO®BLOCK – Elastomeric Bearings

mageba elastomeric bearings, which conform to various international standards, such as the EN1337, DIN4141, BS5400 and AASHTO, are used globally for bridges and other engineering constructions.

Media

Characteristics

The mageba LASTO®BLOCK elastomeric bearing is a reinforced elastomeric bearing manufactured from synthetic chloroprene rubber (CR) or natural rubber (NR).

By using well proven production processes and only highquality raw materials, we can guarantee a long life-span without the need for maintenance.

Main features

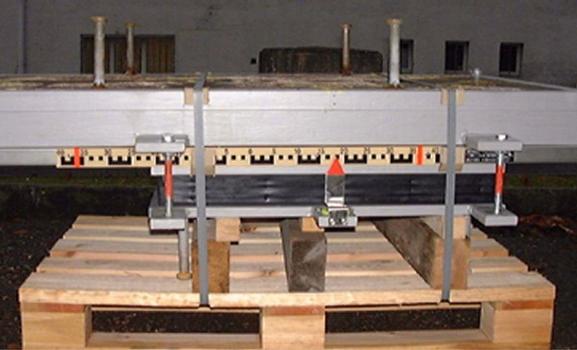

LASTO®BLOCK elastomeric bearings consist of vulcanised elastomeric blocks, reinforced by two or more steel sheets. The vulcanised reinforcing layers of high-strength steel sheeting are fully enclosed in elastomer to ensure absolute corrosion protection and complete freedom from maintenance.

The rubber used is extremely resistant to ageing and weathering influences such as ozone and UV radiation.

Fields of application

mageba LASTO®BLOCK elastomeric bearings are used mainly for bridges and buildings and can be used at temperatures of between -40°C and +50°C. Brief temperature increases up to +70°C can be withstood without problems.

LASTO®BLOCK elastomeric bearings can absorb horizontal movements in every direction and rotational movements around every axis through elastic deformation, thereby allowing forces to be transferred safely from one structural component to another.

Structure

LASTO®BLOCK elastomeric bearings are constructed in layers. This means that they consist of alternating layers of elastomer and steel plates. These alternating materials are chemically fused through a process of vulcanisation, during which the rubber adheres to the reinforcement sheets in such a way as to make the unit resistant to shear and pressure.

Functioning Principles

The mageba LASTO®BLOCK functions primarily as an elastic, load transmitting link between construction elements which need to be connected in such a way as to allow a degree of movement. Vertical loads from the structure itself and traffic loads are transmitted without constraint into the bearing seat. Acceleration and deceleration forces from traffic load, wind forces and centrifugal forces are also efficiently absorbed by the bearings, as well as forces arising from skewed movements of adjacent structural elements.

The materials used and the structural composition of the bearings mean that they are able to accommodate movements resulting from temperature differences between construction elements. Rotational forces from the skewed arrangement of structural components are absorbed by elastic deformation around two horizontal axes.

Materials and Loads

The elastomer is a macromolecular material which demonstrates considerable deformation at low load and which returns to ist initial size and shape when this load is removed.

Steel plates are vulcanised (chemically joined) into the elastomer in order to strengthen it.

LASTO®BLOCK elastomeric bearings are available in synthetic chloroprene rubber (CR) or in the more economic natural rubber (NR) with ozone level "0" in accordance with EN1337.

Standards and external quality control

The LASTO®BLOCK elastomeric bearing conforms with the European standard EN 1337-3 and has successfully passed all tests required for certification with the CE mark.

In addition to internal quality control, LASTO®BLOCK elastomeric bearings are also regularly monitored in accordance with regulations by MPA Stuttgart, an independent supervisory board officially recognised in the field of construction. The role of external quality control is to monitor internal quality control procedures and compliance with the requirements stipulated in the EN1337-3 standard. This external quality control complies with the regulations of the European standard EN 1337 and is a further guarantee of the consistent high quality of mageba products.

Depending on scope, LASTO®BLOCK elastomeric bearings are also available on request with certification according to other standards, for example DIN 4141, BS5400, AASHTO, etc.

Quality

mageba LASTO®BLOCK elastomeric bearings have been tried and tested under demanding traffic conditions and have a long life-span. They have been used successfully around the world for more than 40 years.Qualified personnel, up-to-date production lines and testing laboratories, and quality control at every stage of the manufacturing process all help guarantee the high quality of mageba products.

References

Louisville, Jefferson County, Kentucky, USA, North America - Jeffersonville, Clark County, Indiana, USA (2015)

City of Bankstown, Sydney, New South Wales, Australia, Australia and Oceania - Sutherland Shire, Sydney, New South Wales, Australia (2008)

Similar Products & Services

Relevant Websites

- About this

data sheet - Product-ID

14 - Published on:

02/07/2007 - Last updated on:

17/11/2021

mageba group

mageba group