General Information

| Completion: | 5 April 2013 |

|---|---|

| Status: | in use |

Project Type

| Function / usage: |

Electric power plant Experimental structure |

|---|

Awards and Distinctions

| 2015 |

commendation

for registered users |

|---|

Location

| Location: |

Lockhart, San Bernardino County, California, USA |

|---|---|

| Coordinates: | 35° 0' 38.79" N 117° 19' 50" W |

Technical Information

There currently is no technical data available.

Ultimate Trough

Task definition

Unlike almost all other renewable energy systems such as wind and photovoltaics, solar thermal power plants provide storable renewable energy around the clock and are said to have the potential to deliver solar energy at a profitable cost when needed. The objective of the „Ultimate Trough“ project was to develop a design and implementation for a new lower cost generation of parabolic trough collectors for solar power generation. The new collector was to meet all technical and economic requirements for use in solar fields for thermal power plants with a power capacity of 250 megawatts of electrical power and beyond. It should be 25 percent more cost-efficient than the current standard parabolic trough collector, the Eurotrough, by reducing specific costs (euros/m²) and increasing output. A loop consisting of two collector units (SCAs) of 240 m individual length was to be integrated into a power plant in California. The objective of the project is to demonstrate the planned manufacturing and assembly processes and their expected costs. The measurement of the performance under power plant conditions should increase the planning reliability for upcoming power plant projects.

Solution path

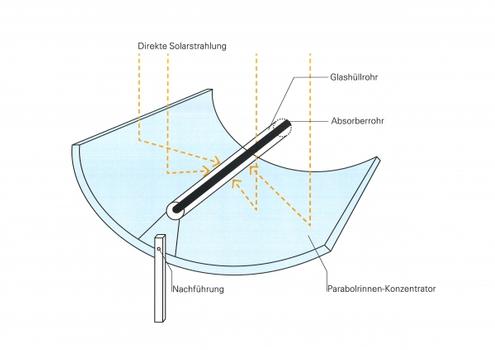

The reflective surface of a uniaxially parabolically curved mirror surface concentrates sunlight onto an absorber tube mounted along the focal line of the mirror. A collector unit is rotated about its longitudinal axis over the course of a day, tracking the sun.

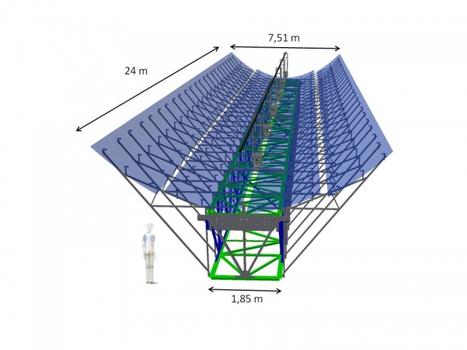

The horizontal wind loads coupled with the extremely low allowable deformations are critical to the design of a suitable collector structure. A resolved box cross-section with dimensions of approximately 1.85 x 1.85 m and a length of 24 m was chosen as the torsionally rigid support structure. This box is formed by four truss disks made of angle sections, each of which is frictionally connected at the chords. The stiffening of the cross-section is achieved by diagonal bars and end bulkheads. There are 24 cantilevered truss arms made of hollow sections on each side of the box side walls, which form the support points for the 48 mirrors measuring approximately 2.0 x 2.0 m.

Glass and steel are the primary construction materials for the Ultimate Trough collector. Commercial power plants use several thousand tons of steel. In this context, a currently typical power plant has an electrical output of 50 MW and thermal storage for uninterrupted operation for up to eight hours after sunset. The choice of steel sections used is of great importance for the cost of the collector. In order to develop a collector that is cost-efficient and can be manufactured worldwide, globally available standard profiles in standard grades (e.g.: rolled profiles and hollow profiles of grade S235) with normal manufacturing tolerances were selected. The production of the steel structures is adaptable to local capabilities in terms of manufacturing methods. Fully automated robot assisted fabrication or simple manual fabrication – this flexibility allows to maximize the value added potential in the country of installation.

By using high-precision assembly fixtures, the high geometric requirements can be achieved despite low tolerance requirements for the individual steel components. A new joining technique, which does not require any fasteners, additionally facilitates the assembly of the components. For the first time, the Ultimate Trough uses clinching technology to join the concentrator parts. In this joining technique, which originated in series automotive construction, sheet metal is joined by local cold forming through a punch with a die in a force-fit and form-fit manner.

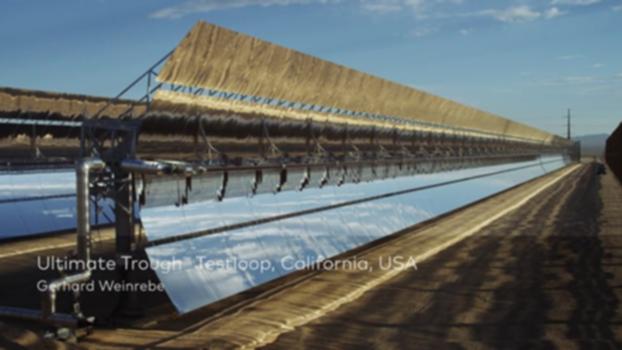

To achieve a significant cost reduction for the collector design, a considerable enlargement of the individual collectors was planned. The cost benefit comes from reducing the total number of collectors and all associated power plant components. As a result, the Ultimate Trough is currently the world's largest parabolic trough collector.

Parallel to the increase in size are disproportionate load increases on the collector. In order to achieve a highly efficient use of materials, possibilities for reducing wind loads were investigated in the wind tunnel. Therefore, for the first time, the Ultimate Trough does not have a closed mirror surface, but has pressure relief slots in the longitudinal direction that reduce wind loads by up to 30%.

Further, the fixation of the mirrors has been modified to compensate for tolerances of the steel structure. A three-dimensional tolerance compensation in an adhesive joint allows for a more precise parabolic shape than before, and thus a very high optical efficiency.

The special engineering achievement lies in the integral approach to design optimization. For example, if the cost of the collector is optimized in isolation, this leads to small collector designs, as pursued by other developers. If, as here, an integral techno-economic approach is taken that considers all cost factors and power plant processes of the solar power plant in an interdisciplinary manner, the optimum lies with large collector concepts, because the somewhat higher collector costs are more than compensated for by significant savings in other areas. In developing the Ultimate Trough, the impact on power plant efficiency, as well as the costs of, for example, cabling, foundations, installation, operation and maintenance, etc., were tracked from the outset, and the impact directly on the cost of electricity was considered.

This interdisciplinary and integral approach can only succeed on the basis of many years of experience and a broad interdisciplinary staffing across all engineering disciplines. The applied approach to solar collector development requires experience and knowledge in civil, mechanical, and automotive engineering, among others.

Summary

Worldwide, the breakthrough of solar power technologies is hindered by the still too high cost of electricity generation and unreliable time availability compared to fossil fuel availability.

Solar thermal power plants such as parabolic trough power plants eliminate this disadvantage by being able to provide storable energy without adding to the price of electricity generation costs. Thus, unlike almost all other renewable energy systems, solar thermal power plants ensure security of supply.

The development of the Ultimate Trough addresses both points and, through its integral optimization approach, enables a substantial step towards overall cost reduction and thus towards independence of solar technology from subsidies and fluctuating political support. The development of the UltimateTrough aims at the economic creation of large-scale power plants, which globally leads to a substantial contribution to renewable energy supply, conservation of fossil resources, and reduction of greenhouse gases.

Explanatory report by Markus Balz and Axel Schweitzer of schlaich bergermann und partner sbp sonne gmbh on submission to the Ulrich Finsterwalder Engineering Award 2015

Participants

Relevant Web Sites

Relevant Publications

- (2015): Von A bis Z optimiert - Das Solarkraftwerk "Ultimate Trough". In: (2015): Ingenieurbaukunst 2016. Ernst & Sohn, Berlin (Germany), ISBN 9783433031261, pp. 140-145.

- About this

data sheet - Structure-ID

20066622 - Published on:

27/11/2014 - Last updated on:

21/09/2017