General Information

| Completion: | 2013 |

|---|---|

| Status: | in use |

Project Type

| Structure: |

Membrane structure Cable net |

|---|---|

| Function / usage: |

Shelter / rain protection |

| Material: |

Steel structure |

Awards and Distinctions

| 2015 |

entry

for registered users |

|---|

Location

| Location: |

Wolfsburg, Lower Saxony, Germany |

|---|---|

| Part of: | |

| Coordinates: | 52° 26' 0.36" N 10° 47' 52" E |

Technical Information

Dimensions

| width | ca. 38 m | |

| length | ca. 55 m | |

| membrane covered area | 1 610 m² | |

| cables | diameter | 20 mm; 24 mm |

| total length | 2 000 m |

Quantities

| structural steel | 130 t |

Materials

| membrane |

ETFE foil

|

|---|---|

| edge girder |

steel

|

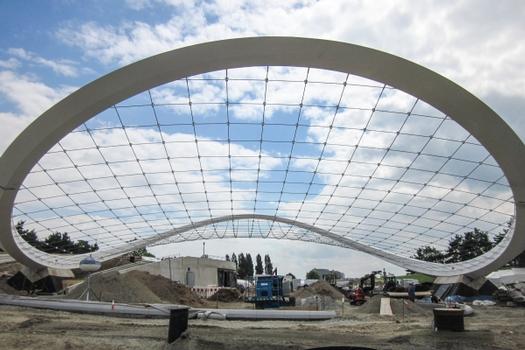

Customer center - roofing of the exit Autostadt Wolfsburg

Task definition

The exit of the customer center of the Autostadt Wolfsburg was to be redesigned. This involved planning an exit attraction on the Autostadt site with a protected test track on which customers can test drive the vehicle assistance systems and inspect the new cars in a parking area.

Parts of this parking area were to be covered by a sophisticated roof structure.

Description of the main supporting structure

The roofing of the customer center exit forms a saddle surface, hyperbolic paraboloid, of about 1600 m².

The main supporting members are.

- Foundations on pile foundation, connected with truss tension band,

- Steel edge beam as compression ring, clamped in 2 foundations,

- Cable net with cable clamps in the nodes, at the same time support points of the membrane

- Membrane PTFE coated fiberglass fabric

The edge beam is a 5-cornered box girder, edge lengths approx. 300 mm to 1,000 mm, internally provided with longitudinal and transverse stiffeners, the shell plates are double curved. Welds longitudinally and transversely ground flat, very high requirements for the evenness of the surface.

The rope net consists of open spiral ropes, suspension ropes d = 24 mm and tension ropes d = 20 mm. In plan projection, there is a square grid with edge length of about 1.50 m. The nodal points are formed from the prestressed clamping plates, steel grade S355, which at the same time provide the connection to the membrane.

The membrane rests on the rope nodes and is connected to them with clamping plates. The membrane was cut to size and welded in the workshop from 4 longitudinal sheets and thus folded in one piece and transported to the construction site. The edge trim consists of a keder rail that is continuously braced to the edge beam. The seal between the membrane surface and the edge beam is formed by the Closerflap, which is welded to the membrane edge and clamped to the edge beam.

Choice of construction materials

The interaction between geometry and material allows for the optimal design of the structure. The steel in the form of the optimized box section takes on compressive forces and bending moments, while the cables in conjunction with the saddle shape carry the surface loads with tensile forces into the edge beam. The saddle shape provides shape retention for positive and negative roof loads. The PTFE coated fiberglass membrane is able to transfer the wind and snow loads to the rope nodes and ensures light transmission while filtering UV radiation.

Explanation of the design

For the test track, the terrain is designed to be slightly hilly. The roofing harmoniously adapts to this terrain shape. The roof has 2 points of contact with the ground and is clamped into the foundations here. The curved roof surface forms a saddle surface, thus taking up the idea of a "leaf in the landscape". The white PTFE membrane filters 80% of solar radiation, protecting against sun and rain.

Special engineering achievement

Combining the materials of concrete, steel sheets, steel cables and PTFE-coated fiberglass fabric with their respective specific requirements, the sophisticated structure was created. Planning, fabrication and erection had to take into account the statically calculated workshop and final geometry determined in test series required in rope and membrane construction. The manufacture of the edge beam in particular deserves attention. The double-curved plates were manufactured using processes commonly used in shipbuilding. The result on the finished structure shows a smooth wrinkle-free surface of the mem- brane.

What are the positive aspects of this particular engineering achievement

?

The Autostadt site has a park-like layout. The test track and the roofing are harmoniously adapted to the terrain due to the lightness created by the shape and choice of materials.

Explanatory report by Eiffel Deutschland Stahltechnologie GmbH for submission to the Ulrich Finsterwalder Ingenieurbaupreis 2015

Participants

Relevant Web Sites

Relevant Publications

- (2017): Double Curvature for Volkswagen. Presented at: Interfaces: Architecture, Engineering, Science, Annual Meeting of the International Association of Shell & Spatial Structures (IASS), Hamburg, 25-27 September 2017.

- (2014): Selbstverankerte Seilnetze – ein leichtes Dach in der Autostadt Wolfsburg. In: Bauingenieur, v. 89, n. 6 (June 2014), pp. 235-245.

- (2014): Stählerner Fittich - Die Überdachung der Ausfahrt vor dem KundenCenter der Autostadt in Wolfsburg. In: (2014): Ingenieurbaukunst 2015. Ernst & Sohn, Berlin (Germany), ISBN 9783433030967, pp. 152-159.

- About this

data sheet - Structure-ID

20066032 - Published on:

18/03/2014 - Last updated on:

17/05/2015