General Information

| Completion: | 20 May 2014 |

|---|---|

| Status: | in use |

Project Type

| Function / usage: |

Bicycle and pedestrian bridge |

|---|---|

| Structure: |

Haunched girder bridge |

| Material: |

Steel bridge |

| Support conditions: |

Structurae Plus/Pro - Subscribe Now! |

| Structure: |

Box girder bridge |

Awards and Distinctions

| 2015 |

Honorable Mention

for registered users entry for registered users |

|---|

Location

| Location: |

Stuttgart, Baden-Württemberg, Germany |

|---|---|

| Address: | Hagelsbrunnenweg |

| Coordinates: | 48° 42' 47.21" N 9° 6' 38.66" E |

Technical Information

Dimensions

| total length | ca. 27.5 m | |

| deck width | 2.20 m | |

| girder depth | 0.450 - 1.240 m | |

| total width | 3 m |

Materials

| deck |

steel

|

|---|---|

| abutments |

reinforced concrete

|

Pedestrian and bicycle bridge Hagelsbrunnenweg, Stuttgart

1. Client's task

The foot and cycle path bridge spans a double-track S-Bahn line and the associated retaining wall and embankment areas in a wooded area in Stuttgart-Vaihingen. The bridge is a new replacement for a wooden bridge that had become obsolete. For reasons of durability, the client wanted the bridge to be made of steel. The existing concrete abutments were to be used for the new construction and adapted accordingly. A specified safety distance had to be maintained from the existing overhead lines of Deutsche Bahn, which runs approx. 30cm below the top of the lower abutment, and beyond which the bridge superstructure was not allowed to project. At the same time, the bridge radius had to overcome a height difference of 1.60m over a total length of approx. 27.5m. The usable width was specified as 2.20m and the height of the guardrail spars as 1.30m. According to the safety specifications of the railroad, a contact protection had to be arranged on both sides directly above each overhead line. During construction and installation, no interference with railroad operations was permitted.

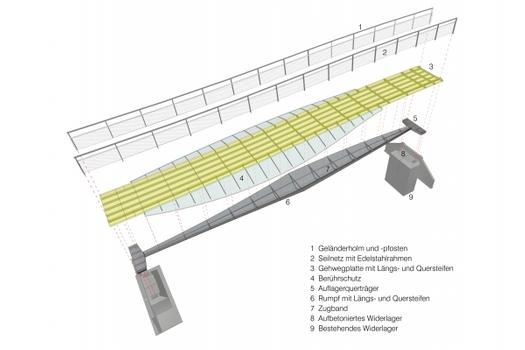

2. Description of the main support structure

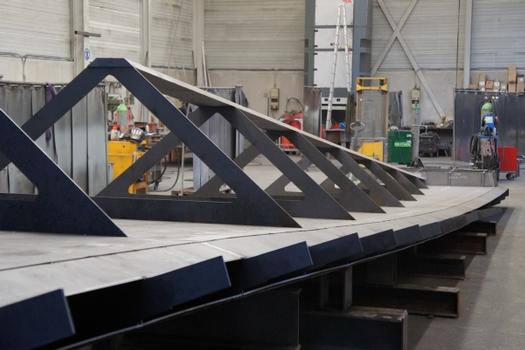

The structural system of the bridge was designed as a statically determinate supported single span girder. The cross section, which was designed as a multi-cellular box girder, consists of a top walkway slab 183mm high and 3000mm wide and an underlying hull with a variable triangular cross section. The width and height of the fuselage decrease at the same rate, so that the inclined side plates could be made of flat plates. The hull reaches its maximum height in the center of the bridge and decreases towards the supports. The total cross-sectional height of the hull and sidewalk is 1240mm at the center of the span and 450mm above the abutments. The triangular hull opens on both sides above the bridge bearings into cross girders arranged on the underside, which transfer the torsional stresses from the box girder via the bearings into the bridge abutments. The cross girders are also used to anchor the tension band, which is in the form of a 50mm thick steel plate and runs along the lower edge of the hull. The box girder is stabilized inside the cross-section by regularly spaced transverse bulkheads. In conjunction with stiffeners placed in the longitudinal direction of the bridge, they reduce the geometric dimensions of the bulge fields. The design principle of the box girder with variable cross-section geometry is demanding in terms of design and manufacturing technology, but very efficient because the steel plates of the upper cross-section section have a full structural contribution.

3. Choice of construction materials

For reasons of robustness and durability, on the one hand, and for manufacturing and installation reasons, on the other, the client preferred a steel construction design. In this way, any interference with rail operations could be ruled out because the new steel bridge could be manufactured almost entirely in the factory and lifted into place in one piece with as little technical effort as possible. The railing was also made of steel or stainless steel and already installed in the factory. In accordance with the regulations of Deutsche Bahn, the contact protection made of glass has an enclosure made of a welded stainless steel profile, which acts as a bounce ladder.

4. Explanation of the design

The design is derived from the geometric boundary conditions, design and manufacturing considerations, and force flow. The 27.5m long bridge has a width of 3m. The height difference of the two bridge ends of about 1.6m is accommodated in the plane of the walkway by curving the bridge radius in opposite directions to avoid functionally and visually disturbing kinks. Since the existing abutments had to be used, the design of the bridge as a single span girder was obvious. The supporting structure could be arranged above the clearance profiles of the urban railroad under the sidewalk, taking into account superstructure deformations and safety spaces. The eastern part of the superstructure has a horizontal lower edge, while the western part has an inclined lower edge that merges into the horizontal above the supports. Both interact with the curved top edge of the superstructure to create visual tension. The edge caps of the walkway are part of the load-bearing cross-section. The outwardly sloping metal sheets of the edge caps form a slender elevation edge, which emphasizes the elegant curve of the walkway slab through the color contrast and sets an accent in the green surroundings. Necessary components of the bridge equipment such as parapet and contact protection are integrated into the design concept. The railing structure was designed to be maximally transparent with a pre-tensioned cable net infill in consideration of the surroundings. The contact protection above the tracks was developed into a design-defining element, which emphasizes the curved shape of the bridge as laterally attached glass wings.

5. Special engineering achievement

The pedestrian bridge is an example of how the above specifications were not understood as a constraint, but rather as a creative stimulus for the design of an unusual bridge structure. Based on the simple static principle of the single-span girder, an elegant bridge structure was designed that takes into account all conditions such as the reuse of the existing abutments, the comparatively large difference in height over a relatively small span, the safety requirements on the part of the railroad and, last but not least, a limited financial budget. Particularly careful detailing and the color scheme make a substantial contribution to the design quality. Necessary components of the bridge equipment, such as parapets and contact protection, are integrated into the design concept with maximum sensitivity. In particular, the contact protection required for safety reasons was deliberately developed into a design-defining element. The result is a filigree structure in which construction and design merge into a single unit in an optimal manner.

6. What are the positive effects of the special engineering achievement?

The bridge on Hagelsbrunnenweg is the result of a holistic way of thinking that knows how to combine both artistic and technical aspects to create engineering art. The structure was realized within the specified budget at a gross price of 3450 EUR/m².

Explanatory report by Engelsmann Peters Beratende Ingenieure on the submission to the Ulrich Finsterwalder Ingenieurbaupreis 2015

Participants

- Bernd-Friedrich Bornscheuer (checking engineer)

Relevant Web Sites

There currently are no relevant websites listed.

Relevant Publications

- (2015): Die Kunst, das Einfache zu gestalten - Fuß- und Radwegbrücke Stuttgart-Vaihingen. In: (2015): Ingenieurbaukunst 2016. Ernst & Sohn, Berlin (Germany), ISBN 9783433031261, pp. 34-41.

- (2014): Neubau Fuß- und Radwegbrücke Hagelsbrunnenweg, Stuttgart. In: Stahlbau, v. 83, n. 11 (November 2014), pp. 826-831.

- About this

data sheet - Structure-ID

20066616 - Published on:

11/11/2014 - Last updated on:

21/04/2016