Ultra-precise calculation

The current extension work at the Frankfurt AIRRAIL CENTER over the station for inter-city trains posed various challenges for structural and checking engineers. Precision work is called for here because the support structure for the ends of the building is so complex that it cannot be broken down into separate evaluation schemes.

Media

Founded in 1976, König & Heunisch Planungsgesellschaft (KHP), Frankfurt am Main, offers a comprehensive range of engineering consultancy services from conventionally reinforced, prestressed or composite steel-concrete to timber engineering. The company's main focus is structural engineering, which covers planning, contract award preparation, structural analysis, construction supervision and management. As several of the company's owners are approved checking engineers for structural analysis, the checking of structural engineering designs is another of KHP's core competences. With a workforce of more than 60, the company attaches great importance to a high level of professional, state-of-the-art skills plus punctual completion however large the project may be. At the same time, the company's engineers are always keen to remain within a client's budget.

Fully linked

Dr. Klaus Schneider from KHP has been contracted to check the structural engineering analysis of the AIRRAIL CENTER directly above the station for inter-city ICE trains at Frankfurt Airport. Once completed, this major engineering challenge will provide a reliable link for road, rail and air traffic in a futuristic building at the second-largest airport in Continental Europe. Some 94 500 m² of office space, 5900 m² for retail and catering, an imposing hotel with 34 500 m² of floor space – the figures alone are impressive. The centre is scheduled to open in December 2009. Since 2006 the construction site at Frankfurt Airport has been bustling with activities to meet the deadline of project partners IVG Immobilien AG and Fraport AG. The structural engineering input was carried out by a consortium consisting of Krebs & Kiefer Beratende Ingenieure, S.A.N. Darmstadt GmbH and Munich-based bwp Burggraf + Reiminger Beratende Ingenieure GmbH. Responsible for the detailed design of the building, which is being constructed under the project management of Ed. Züblin AG, were the architects of J•S•K Dipl. Ing. Architekten.

Ensuring the loadbearing capacity

Designed by Hadi Teherani from BRT Architekten, the Frankfurt AIRRAIL CENTER has been built in two stages. Supported on 43 fish-belly girders spaced 15 m apart, the platform on which the new centre will be finished by the end of this year consists of a 280 mm thick steel-concrete slab in the shape of a surfboard! Like the glass dome that is to be retained as a roof over the entrance to the ICE station, it has been in existence for about 10 years already. Two Hilton hotels have planned to move into the eastern end and the new Frankfurt office of KPMG is to take up residence in the western part of the centre this year. No easy task for structural and checking engineers because the planned superstructure and the existing construction have to be matched to each other. "The main challenge for the structural engineers was to apply the load of the building to the bearing points designed for the existing structure,” comments Dr.-Ing. Thomas Geppert, Project Manager for structural analysis checking at KHP. The geometry of these support points, which does not coincide with the grid of the superstructure, is already defined by the truss geometry of the fish-belly girders. Extensive bracing structures were therefore required and the options for positioning bracing cores and slab walls were extremely limited.

Firmly anchored

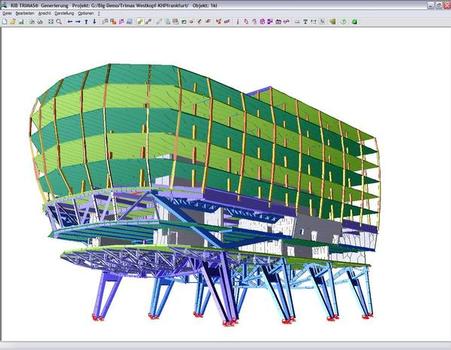

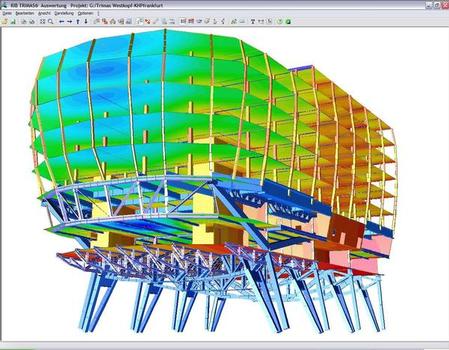

There is a special situation at the two ends of the long building, where the superstructure has an ascending overhang that projects so far beyond the last fish-belly girder that additional labour-intensive bracing structures were required. Due to the different uses of the two ends of the building, their structures are completely different. The eastern end has a 3D steel framework structure on the middle floors of the hotel where a ballroom is planned. The loads are transferred by steel pylons, integrated via connectors, to a bracing core. At the western end the loads will be braced by various steel framework girders and two steel frame constructions in the lower parking decks of the superstructure, which together with the bracing cores form a complex 3D loadbearing structure. "A view of this area on separate corresponding 2D systems would have led to major uncertainties in the analysis of the results,” reports the project manager of Dr. Klaus Schneider's team of checking engineers. For the western end, Dr.-Ing. Thomas Geppert therefore created a three-dimensional model of the whole system including all suspended floors, girders, cores and supports. To do this, he used RIB's FEM system TRIMAS®. Using TRIMAS®, Dr. Geppert was able to model and calculate the entire loadbearing system of the western end including the complex load transfer within the entire structure. By using different layers within the model, the analysis of the dimensioning results can be reduced to individual components and the evaluation can be displayed very clearly.

"We have been using the structural engineering applications of RIB for analysis and design tasks for more than 25 years now,” adds manager Klaus Wörner. Besides TRIMAS®, several structural concrete design applications from the RIBTEC® portfolio, e.g. BEST, RTbalken or ZWAX, were also used for checking the analyses for the AIRRAIL CENTER. "The reinforcement of the 32 cores of the building is particularly easy to design with ZWAX,” he points out. "We're glad to be able to rely on proven, successful systems for projects such as these.”

References

Structure Types

- About this

data sheet - Product-ID

6274 - Published on:

15/05/2013 - Last updated on:

30/01/2016