ROBO®SMART for Bearings

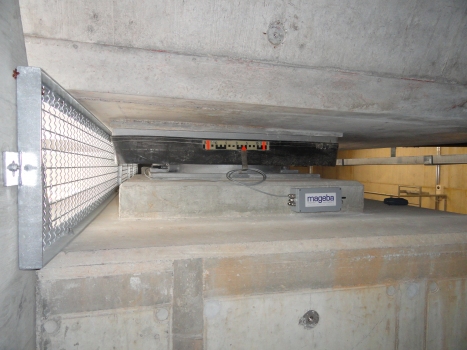

The ROBO®SMART for structural bearings is a small, self-powered and integrated acquisition unit. The precise and durable sensors with robust electronics transfer the measured data via 3G GSM network to a mageba server for 24-hour online data presentation and access via secure web interface. The ROBO-SMART sensors for structural bearings can be assembled directly in the factory or as an upgrade on site.

Introduction

Structural bearings allow - in the intended direction(s) - relative displacements and/ or rotations between structural members whilst transmitting loads in the other direction(s). Their life expectancy depends on traffic loading, accumulated movements, climatic conditions, and above all the type of bearing and the quality of its design, fabrication, and installation. The use of a ROBO®SMART monitoring system can enable the life-cycle cost of a bearing to be optimized. Using such a system, the structure's behavior can be assessed on the basis of continuously measured parameters, with data viewable online at any time of day or night.

mageba smart bearings

mageba has an extensive track record of supplying structural health monitoring (SHM) systems for various applications and is also a leading manufacturer of bearings for bridges and other structures. Combining the company's expertise in both fields enables it to now offer "smart" bearings. Any type of bearing from mageba's wide range can be designed and manufactured with an integrated SHM system – considerably simplifying its installation and reducing the total cost of ownership. Therefore, the potential use of an SHM system should ideally be considered already when specifying the bearing. Previously installed bearings can also be retrofitted with an SHM system where required.

Features

- Small, self-powered and integrated acquisition unit

- Precise and durable sensors

- Robust electronics

- Data transfer via 3G GSM network

- 24-hour online data presentation via secure web interface

- Download of measured data

- Assembly with bearing in factory or on site

Sample benefits for the end user

- Measurement of accumulated movements leading to optimisation of maintenance intervals

- Warnings in case of passing of certain thresholds (e.g. movements, loads, rotations)

- Real-time availability of various parameters (e.g. structural and air temperature, bridge deck displacement, traffic load, etc.)

- Measurement of maximum loads and movements for bearing replacement projects, leading to optimised design of the new bearings/expansion joints based on actual required load, rotational and movement capacities

Similar Products & Services

Relevant Websites

- About this

data sheet - Product-ID

7479 - Published on:

15/03/2017 - Last updated on:

17/11/2021

mageba group

mageba group