Expanded applications with ATIS Cableskin® - the long-term corrosion protection system for cables

ATIS Cableskin® is a corrosion protection system where butyl rubber tapes are applied to the cable surface in two layers. Due to the cold-welding properties of the material, a robust coating of the cable that is virtually impermeable against oxygen and hydrogen is formed. In the spring of 2016, the German approval – Allgemeine Bauaufsichtliche Zulassung Z-30.11-41 – for ATIS Cableskin® was extended by the Deutsches Institut für Bautechnik (DIBt) and expanded by some interesting applications at the same time.

UV-protection function

This long-term corrosion protection system is now also used specifically as UV-protection for stay cables. This specifically applies to cables with PE ducts. The outer layer of the wrap, the covering layer, is applied with an extremely UV-resilient PE carrier film on the outside that safely and permanently protects the existing PE duct from aging through UV-effects. Tests in accordance with DIN EN ISO 11341, in which an ATIS Cableskin® sample successfully resisted the required stress twice in sequence and without any complaints, documented the reliable protection effect of this system.

Furthermore, spectral-densitometrical examinations on the red wrap fitted on the valley bridge Obere Argen at the A96 in 2012 showed no visible changes to the typically particularly sensitive red shade.

Two other large applications on bridges in Texas (USA) with a total of 14,000 m² wrapped PE cable surface have already been implemented successfully. Another comprehensive application is currently fitted on the cables of the Carlos Fernández Casado bridge in Spain.

Reinforcement of PE ducts

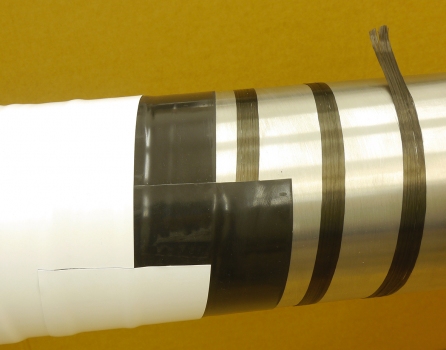

In the scope of this Spanish project, ATIS Cableskin® is used as a reinforced wrap for the first time. Alpin Technik und Ingenieurservice GmbH was charged with sustainably restoring the badly damaged and pre-stressed ducts of the parallel strand cables injected with grouting mortar. In addition to comprehensive robot-supported PE welding work, this also included the production of an effective long-term corrosion protection and additional UV protection with ATIS Cableskin®.

The first reinforcement of the coil for radial tensions with carbon-fiber strands is a special feature here. These are applied directly onto the PE surface to be reinforced by the same winding robot just before the butyl rubber bands are fitted, and then covered. This measure is able, among others, to considerably strengthen PE tubings already damaged by too-high injection pressures, and to thus clearly increase the service lives of the bridge ropes. This effect has been successfully proven in comprehensive stress tests in the company's own test facilities.

Active and passive dehumidification systems

The system was also expanded by the ability to combine it with active and passive dehumidification systems in the scope of the license extension at the DIBt. This solution has already been used successfully on a suspension bridge in Norway. It is in high demand and already established on the international market and is also about to grow in importance in Germany, specifically for the restoration of existing buildings.

Further protection effects

The corrosion protection system ATIS Cableskin® is now also approved by the DIBt for fully closed cables in which cable filling medium escapes on the free length after installation. The high tear-resistance of the coil that is based on the use of PE films worked into the butyl rubber guarantees a high resistance against escaping cable filling medium.

Properties of the long-term corrosion protection system ATIS Cableskin®

In addition to UV protection and reinforcement of PE ducts, in addition to dehumidification and prevention of escape of cable filling medium, ATIS Cableskin® is an extremely efficient long-term protection against corrosion in load-bearing cables, which is characterized by many properties and benefits.

Technical properties:

- robust multi-layered system of resilient materials with approx. 2.6 mm layer thickness

- very good adhesion and interlocking with the cable surface

- highly elastic behavior through which all temperature variations and load movements are absorbed.

- no bursting off or tearing at relative shifts of the cable wires or escape of cable filling medium

- approved for corrosion classes C5 I and C5 M

- verifiable service life of more than 60 years

Benefits in application:

- quick, cost-efficient and VOC-free application of the butyl rubber tapes

- application highly independent from climate condition

- no scaffolding or housing required, leading to very low traffic impairment

- no elaborate preparation of the cable surface, such as blasting or sweeping and therefore no disposal of environmentally hazardous substances

- existing coatings can be wrapped over

- production of inspection points for long-term monitoring

- very good inspection capacity of the cables, also with the MI procedure

ATIS Cableskin® provides an integrated system that meets both the required service life of cable structures of at least 100 years and environmental-protection-relevant and health aspects.