Construction of Hirschhagen Tunnel, Germany’s second longest motorway tunnel

The construction of the A 44 motorway between Kassel and Herleshausen is an important part of the trans-European motorway network. After its completion, the A 44 will efficiently connect the Benelux States in the West and Poland in the East. In the section between Kassel and Herleshausen, the construction of the Hirschhagen Tunnel was necessary because of the local topography.

Media

The tunnel is designed as a double tube tunnel with two lanes each. The tunnel tubes are connected with each other by cross passages. The northern tunnel tube has a length of 4,128 m, and the southern tube has a total length of 4,187 m. After its completion, the Hirschhagen Tunnel will be Germany's second longest motorway tunnel.

The tunnel portals are being built using open cut tunnelling. Tied-back bored pile walls and a sheeting wall system are used for stabilizing the excavation at the western portal. Additionally, a vertical end wall with lateral retaining walls is being built in this area. The cover above the crown measures up to 80 m deep. Both tubes are being built using conventional tunnelling methods and run mainly through coloured sandstone formations. Tunnelling is proceeding simultaneously from both tunnel portals.

Undercrossing of the Losse River is especially difficult

The undercrossing of the Losse River near Eschenstruth is especially difficult. Underneath the river, there is a porous mixture of clay and sand deposits that is saturated. For undercrossing the river, an approx. 300 m long gallery is being built at a depth of 15 m through which the water will be drained from the surrounding ground.

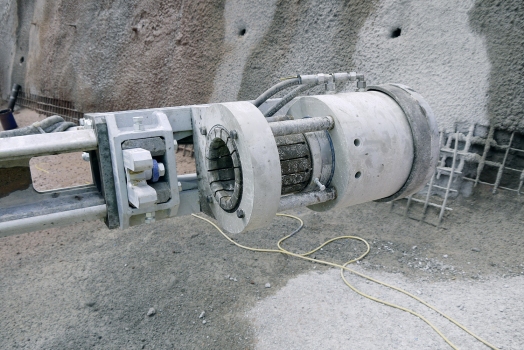

The tubes are ventilated via a more than 80 m deep shaft, the inner lining of which will be resistant to pressurized water and fitted with single-layer waterproofing. DSI produced and supplied the AT– 139 Pipe Umbrella System for the construction of the two tunnel tubes. The system is especially suitable for tunnelling in soft ground that is prone to subsidence and has the following principal advantages:

- Fast self-drilling installation

- Smallest possible stress relaxation due to an immediate support of the borehole wall during installation

- Accurate installation due to a minimized annular gap

In this project, a newly developed squeezed connection by DSI was used for the first time for the fast and safe connection of the casing tubes. In addition, DSI supplied numerous ground support products such as SN Anchors, hollow bar anchors as well as the AT–TUBESPILE™ and self-drilling spiles for pre-support.