Building a residential complex with heatable formwork

Around 30 km to the north of Helsinki, the so-called Domino Complex is currently being realized – for the construction company, this has meant maintaining an extremely tight construction schedule from the beginning onwards. This brought great challenges particularly regarding the reinforced concrete work carried out during the long Scandinavian winter.

Media

The Domino-kortteli Residential Complex in the Finnish town of Sipoo situated on the south coast of Finland features two buildings with up to six floors. On a total of 4,750 m² building floor area, retail spaces and restaurants have been realized in the lower floors while apartments and a nursing home fill the upper storeys. In terms of providing an environment suitable for elderly residents, the facility operator will also be offering a wide range of supporting services together with home care-related services. A very short construction time was designated for the execution of the building work. Joint Venture TYL Onnenrakentajat consisting of Helsingin Rakennusteho Oy and Keski-Suomen Betonirakenne Oy, together with PERI's Finnish engineers, developed an efficient and cost-effective formwork solution for realizing the reinforced concrete work.

Concreting with a heatable formwork

Construction companies in Finland frequently use prefabricated parts in the colder season in order to avoid the problems arising from in-situ concreting at low temperatures. This requires, however, longer lead-times because the planning – including the joints and anchor points – must take place at a correspondingly early stage. Due to the particularly tight construction schedule, the contractor therefore decided in favour of on-site concreting operations.

A solution had to be found so that concreting could take place efficiently and without frost damage also at sub-zero temperatures. Together with the PERI experts, the construction site team planned the use of a new, heatable formwork system. The heating of the formwork is a normal procedure in Finland as the heat supply ensures an uninterrupted hydration process of the concrete even at temperatures below freezing point.

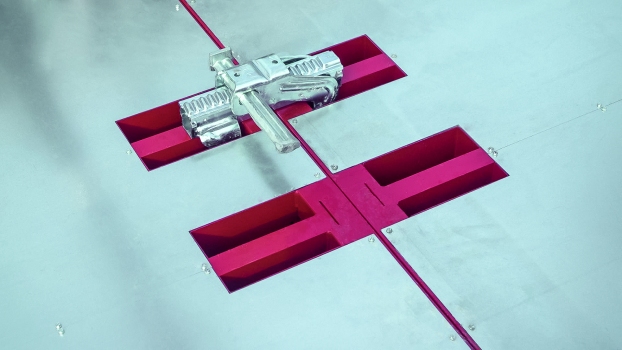

The panel formwork elements of the MAXIMO System are only supplemented with heating elements for use in winter. Assembly of the panel formwork and heating elements take place horizontally, with each heating element being quickly installed by means of two mounting bolts on the frame corners respectively. The majority of the system components can therefore be used during the summer as well as winter, and the investment required for use in winter is consequently kept to a minimum. All the advantages of the well-engineered panel formwork system, with the tie technology fitted from one side only, can also be used in winter with mounted heating elements.

Early striking of the slabs saved valuable time

Also for the construction of the ceilings, Keski-Suomen Betonirakenne Oy considered a range of solution options with the formwork provider – and then decided in favour of panelized slab formwork. Last but not least, construction work has greatly benefitted from using SKYDECK particularly regarding logistical demands as the easy to handle, lightweight aluminium system components could be effortlessly and quickly transported around the construction site.

In order to quickly familiarize users on the jobsite with the unknown formwork systems, PERI Finland provided an experienced supervisor. As a result, the construction team was able to minimize working times, in spite of the required introductory period particularly regarding the forming of the slabs, and could also maintain the very tight schedule.

Structure Types

- About this

data sheet - Product-ID

7447 - Published on:

16/01/2017 - Last updated on:

16/01/2017