168 Tonnes Mass Damp India’s Longest Sea Bridge

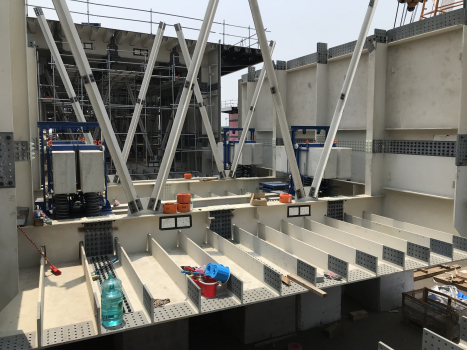

Spans of up to 180 metres make India’s longest sea bridge from the city of Mumbai to the harbour a challenge, since the bridge is made of steel. This would lead to vertical vibrations of up to 300 mm with side wind. MAURER damped critical areas with special dampers: The dampers with a mass of up to 4,800 kg in each case reduce vibrations by a factor of 15. Additionally, vertical guides and hydraulic dampers control the large vibrating damper masses. The system is designed for a service life of 50 years.

Media

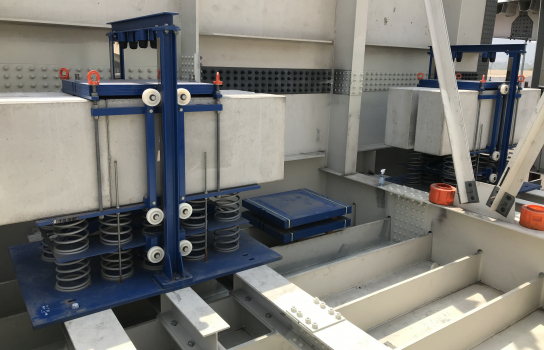

A combination of vertical guide and hydraulic dampers controls the weight

The Mumbai Trans Harbour Link (MTHL, also known as Sewri Nhava Sheva Harbour Link) will be 21.8 km long and connects the city of Mumbai with Navi Mumbai. India’s longest sea bridge is designed to accommodate 70,000 vehicles per day on six lanes from the end of 2023 and reduce travel time from two hours to 20 minutes. This reduces traffic jams and enables further development of the harbor region.

The overall project consists of four construction packages. MAURER delivered a total of 1,100 elastomeric bearings, 461 spherical bearings, 160 pot bearings, 880 m of expansion joints, and 40 vibration dampers. “The vibration dampers posed the real challenge,” project manager Dipl.-Ing. Peter Huber from MAURER reports. “That is why we developed them in coordination with JFE Engineering Corporation, the contracting engineering firm, for the situation on-site, calculated them, and will fine-tune them following installation.”

Steel plus wind plus large spans

On the relevant 1.75-kilometer-long steel bridge section, several factors, which amplify vibration, come together:

- Huge spans of 100 to 180 meters.

- A steel box girder with an orthotropic steel deck, which is a very lightweight construction deriving its high load-bearing capacity from numerous stiffenings. Concrete would not have been an option due to its high self-weight. Steel is more lightweight but also softer, more elastic, and thus vibrates more strongly.

- Side winds lead to so-called vortex shedding in the lee of the bridge from a wind velocity of approximately 20 m/sec. If their frequency is equal to the natural resonance of the bridge, this can lead to vibrations with amplitudes of up to ±300 mm in the center of the bridge sections.

- Since the spans are so large, the natural frequency is very low and lies below 0.8 Hz.

In principle, the orthotropic steel decks would tolerate this vibration over a relatively long period. But for reasons of riding comfort and service life, significant damping was required.

Dampers reduce vibration by a factor of max. 15

To that end, MAURER developed Spring-Mass-Dampers (MTMD-V) with a tuned mass of up to 4,800 kg in each case. The mass mainly consists of concrete. A variable number of steel plates lie on top of it, with which the damper mass can be subsequently adjusted precisely to the actual natural frequency of the bridge.

The damper mass rests on up to 20 helical steel springs. On these, it vibrates up and down by up to ±400 mm at the pre-calculated amplitude. It, therefore, decreases the bridge deck vibration by a factor of approximately 15 to a maximum of ±20 mm. This is effectively reducing fatigue in the bridge deck.

Vertical guide and additional hydraulic dampers

This relatively high vibration amplitude of the mass in the damper creates enormous stress in the springs; the demands on the strength of the spring steel were accordingly high. Additionally, the mass must always stay in control – in every direction. In order to ensure the precise vibration of the mass vertically and thus efficient functioning, high-quality vertical guides with ball bearings were integrated. Hydraulic dampers were installed to decelerate the mass. They prevent the spring system below the mass from reaching the limit of its displacement capacity and damaging the springs.

The hydraulic dampers were designed to be nearly frictionless and wear-free in the piston guides and seals: with a non-contact internal seal. The entire damper system was tested over a length of 400 km accumulated vibration amplitudes. This resulted in temperatures of up to 160 °C, which the system withstood without wear or leakage. In other words: Even with ongoing winds, there is neither fatigue in the springs nor wear in the hydraulic dampers. Bridge vibration is thus effectively and permanently reduced for 50 years and longer.

The spring-mass plus hydraulic damper design needs relatively little space. This made the entire construction more lightweight and facilitated the handling for installation. The vibration dampers were manufactured entirely in Munich and then lifted into the bridge deck and fastened on-site. “This was a stipulation of JFE to fulfill high-quality requirements and minimize installation risks,” Huber reports.

The planning engineering firm JFE was already familiar with the MAURER technology and expertise from the SkyPark of the Marina Bay Sands Hotel in Singapore.

References

Structure Types

- About this

data sheet - Product-ID

8038 - Published on:

13/04/2023 - Last updated on:

13/04/2023

MAURER SE

MAURER SE