Failure Behaviour of Bonding Interface for the Continuous Slab Track Structure Under Temperature Load

|

|

|||||||||||

Bibliographic Details

| Author(s): |

Miao Su

Gonglian Dai |

||||

|---|---|---|---|---|---|

| Medium: | conference paper | ||||

| Language(s): | English | ||||

| Conference: | IABSE Conference: Bridges and Structures Sustainability - Seeking Intelligent Solutions, Guangzhou, China, 8-11 May 2016 | ||||

| Published in: | IABSE Conference, Guangzhou, China, 8 – 11 May 2016 | ||||

|

|||||

| Page(s): | 106-113 | ||||

| Total no. of pages: | 8 | ||||

| Year: | 2016 | ||||

| DOI: | 10.2749/222137816819258302 | ||||

| Abstract: |

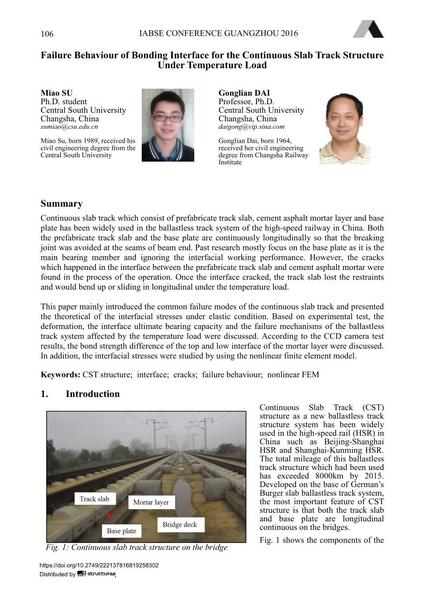

Continuous slab track which consist of prefabricate track slab, cement asphalt mortar layer and base plate has been widely used in the ballastless track system of the high-speed railway in China. Both the prefabricate track slab and the base plate are continuously longitudinally so that the breaking joint was avoided at the seams of beam end. Past research mostly focus on the base plate as it is the main bearing member and ignoring the interfacial working performance. However, the cracks which happened in the interface between the prefabricate track slab and cement asphalt mortar were found in the process of the operation. Once the interface cracked, the track slab lost the restraints and would bend up or sliding in longitudinal under the temperature load. This paper mainly introduced the common failure modes of the continuous slab track and presented the theoretical of the interfacial stresses under elastic condition. Based on experimental test, the deformation, the interface ultimate bearing capacity and the failure mechanisms of the ballastless track system affected by the temperature load were discussed. According to the CCD camera test results, the bond strength difference of the top and low interface of the mortar layer were discussed. In addition, the interfacial stresses were studied by using the nonlinear finite element model. |

||||

| Keywords: |

cracks interface non-linear finite element method (FEM) failure behaviour CST structure

|

||||