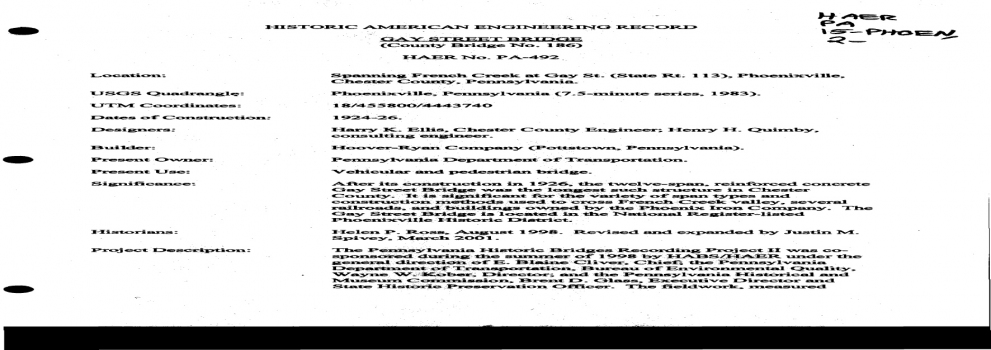

General Information

Project Type

| Structure: |

Deck arch bridge |

|---|---|

| Function / usage: |

Road bridge |

| Material: |

Reinforced concrete bridge Structurae Plus/Pro - Subscribe Now! |

Location

| Location: |

Phoenixville, Chester County, Pennsylvania, USA |

|---|---|

| Address: | Gay Street |

| Crosses: |

|

| Replaced by: |

Gay Street Bridge (2009)

|

| Coordinates: | 40° 8' 8.77" N 75° 31' 7.03" W |

Technical Information

Dimensions

| main span | 41 m | |

| total length | 283.01 m | |

| span lengths | 4 x 9.14 m - 4 x 28.35 m - 41 m - 28.35 m - 2 x 20.73 m | |

| number of spans | 12 | |

| abutments | number | 2 |

| piers | thickness | max. 3.66 m |

| number | 11 |

Materials

| deck |

reinforced concrete

|

|---|---|

| piers |

reinforced concrete

|

| arches |

reinforced concrete

|

| abutments |

reinforced concrete

|

| piers on arch |

reinforced concrete

|

Significance

After its construction in 1926, the twelve-span, reinforced concrete Gay Street Bridge was the longest such structure in Chester County. It is significant for the variety of span types and construction methods used to cross French Creek valley, several railroads, and buildings owned by the Phoenix Iron Company. The Gay Street Bridge is located in the National Register-listed Phoenixville Historic District.

Introduction

Located in the borough of Phoenixville in northeastern Chester County, the Gay Street Bridge is an unusually long and complicated example of a multi-span reinforced concrete structure from the first quarter of the twentieth century. This form slowly gained popularity as an economic means of spanning medium- and long-distance valley crossings. When completed, the bridge was the longest of its type in the county. Consulting engineer Henry H. Quimby created the final design, elaborating on an alignment and preliminary design devised by Chester County Engineer Harry K. Ellis. The structure was erected by the Hoover-RyanCompany, based in nearby Pottstown, Montgomery County. The history of the bridge and its location is intertwined with the business activities of the Phoenix Iron Company, Phoenixville's largest employer, illustrating the firm's influence on borough and county politics. Both of the bridge's engineers, in fact, had been employed by Phoenix Iron. The new bridge crossed directly over several buildings belonging to the company. The use of reinforced concrete reduced maintenance costs and took advantage of locally available materials such as sand, stone, gravel, and steel. By selecting a reinforced concrete design with a large steel component, native son Ellis kept construction costs in the local economy and took advantage of the Phoenix Iron Company's proximity.

Phoenixville was dominated by the industrial powerhouse of Phoenix Iron from the mid-nineteenth century until after the end of World War II. With the financial support from the Pennsylvania and Reading railroads, Phoenix Iron Company (later Phoenix Steel) was able to expand its operations and mill facilities. The decade leading up to the construction of the original Gay Street Bridge in 1883 was a time of phenomenal growth for Phoenix Iron. Awarded the contract to New York's Metropolitan Elevated Railway in January 1879, the firm smelted an immense amount of iron, approximately eighty million pounds for that project alone. Anticipating more orders, Isaac Reeves, grandson of company founder David Reeves, instituted several costly improvements to the plant, such as water and rail lines to the new mills. The entire facility grew in either direction from the foundry on Main Street. To improve access between its various operations, Phoenix Iron designed and erected an elevated iron viaduct to carry the borough's Gay Street across French Creek Valley and above the company's works.

Description

The Gay Street Bridge carries State Route 113 over French Creek, Taylor, and Mill streets, the abandoned site of the Phoenix Iron Company, and several railroad tracks. Its total length of 928'-6" includes four girder approach spans on an 8.5-degree curve and eight open-spandrel arches on a 77-degree skew. Located entirely within the Borough of Phoenixville, the bridge links an urban residential area to the north with the central business district to the south. The structure is located in the National Register-listed Phoenixville Historic District, which is significant for its location as the home of Phoenix Iron, as the commercial center of northeastern Chester County, and as a locally outstanding collection of eighteenth-, nineteenth-, and twentieth-century domestic and commercial architecture.

It may seem unusual to have a reinforced concrete bridge in Phoenixville, with its economy so heavily dependent on steel. The structure does in fact include large amounts of locally manufactured steel, but a reinforced concrete design was chosen for its greater economy, durability, and aesthetic benefits. The use of reinforced concrete in arch bridges was popularized in the last decade of the nineteenth century by Fritz von Emperger and Edwin Thacher. Their bridges were closed-spandrel designs, with a layer of fill between the arch and the roadway. The open-spandrel deck arch design, where the roadway is supported by a series of columns on top of the arches, came along during the first decade of the twentieth century. The design was especially suitable tor spans longer than one hundred feet because the open spandrels required much less material. The economic savings of material, use of local unskilled labor, and increased understanding of the reinforced concrete's structural behavior enabled it to eventually supplant the area's total reliance oh metal bridges.

Because of the Gay Street Bridge's location over active railroad tracks and industrial buildings, alignment and erection procedure were major factors in its design. Ellis' drawings from late 1922 document the process of choosing an alignment for the new structure. His primary goal was to eliminate an offset intersection at the existing bridge's north end, which met Vanderslice Street about a hundred feet west of Franklin Avenue. The new bridge would include a curve to bring its axis into alignment with Franklin Avenue. Ellis first considered a scheme with a gradual curve over French Creek, but this alignment passed over the corners of shop buildings owned by Phoenix Iron. Recognizing that crossing over the buildings was inevitable, Ellis drew a second scheme with a sharper curve on the south approach and a straight alignment across the creek. Although the second scheme passed over more of the buildings, its straighter alignment would be easier to construct.5 Before committing to the expense of a new bridge, the County Commissioners appointed a panel of viewers who met several times in late 1922 and 1923. The viewers examined the old bridge, the borough's finances, and property damage claims, and ultimately decided in favor of the second alignment.

The Phoenix Iron Company's buildings, since demolished, were the reason for the Gay Street Bridge's most outstanding feature, its 134'-0" open-spandrel arch span. In order to minimize the length of this span, Ellis proposed constructing its piers parallel to the buildings, resulting in a skew of 77 degrees relative to the bridge's axis. This skew was repeated on the other spans, probably because it worked well with railroad tracks crossing the site. The presence of buildings beneath the bridge also determined the erection procedure. It would have been difficult to construct traditional ground-based formwork for pouring a concrete arch reinforced with steel rods. Instead, consulting engineer Henry H. Quimby chose to reinforce the arch with structural steel shapes, somewhat like von Emperger and Thacher's early designs. The forms could then be hung from the ribs, and concrete poured around them, without interfering with the buildings below. The multi-centered concrete arch ribs, spaced 24'-0" on center, taper from 12'-0" wide and 4'-0" deep at the skewbacks, to 9'-0" wide by 2'-2" deep at the crown. Inside each rib are three lines of steel plate girders, with 4" of concrete cover top and bottom and a constant transverse spacing of 3'-7-1/2". The plate girders have webs 1/4" thick and riveted flanges consisting of four 5" x 3-1/2" angles.

According to construction photographs in the collection of Ellis9 son Brower, at least some of the 93'-0" arch spans contain similar plate girder reinforcement. Like the 134'-0" span, the multi-centered concrete arch ribs are spaced 24'-0" on center, and taper from skewback to crown. Quimby's plans show the plate girders and an alternate scheme of reinforcement using traditional steel bars, although it is unclear whether the alternate scheme was used in any of the 93'-0" arch spans. The 68'-0 arch spans also have two ribs each, but these are elliptical rather than multi-centered, tapered in thickness but not in width, and definitely reinforced with steel bars. In order to keep traffic moving on the Pennsylvania Railroad's Schuylkill Valley Division below, the 68'-0" arches were poured on steel truss centering.

The south approach roadway rises on a 6.25 percent grade and is supported by the stone walls of the old bridge. Reinforced concrete walls, 12" thick, support the outside edge of the sidewalks and provide an appearance consistent with the new bridge. The reinforced concrete girders of the first span, however, are supported directly on the old stone abutment. Five lines of girders support spans 1 through 4. Each girder is 14" wide and 30" deep, and was cast integrally with the bridge deck. Unlike the heavy piers of the main arch spans, the girders are carried on concrete column bents. Each bent has two columns measuring 27" by 30" and supporting a cross girder 27" wide and 42" deep. On the north end, the abutment does not align with the old structure, and consists of 48'-0"-long reinforced concrete wing walls enclosing earthen fill.

The deck carries a 27'-0"-wide roadway with 7'-2" concrete sidewalks on either side, for an overall width of 43'-0" including parapets. The roadway slab is 12" thick and supported directly on the girders in spans 1 through 4. On the open-spandrel arch spans, the floor system is more complicated. Rising from the arch ring at 11'-10" intervals, spandrel columns support a series of smaller arches below the roadway. The smaller arches carry transverse floor beams spaced 5'-11" on center. The floor beams are encased in concrete and support a jack arch floor with a minimum thickness of 10". Floor reinforcement consists of 3/4" square steel bars throughout. Above each spandrel column, the floor beam projects 5'-0" to form a sidewalk bracket. The parapets are 1 '-0" thick and 4*-0" high, incised with rectangular panels and punctuated by pilasters above each sidewalk bracket. Above the major piers, tall reinforced concrete obelisks originally served as light standards, but have since been cut down to the parapet level.10 Modern aluminum light poles now illuminate the bridge. Stairs with steel pipe handrails descend from the east sidewalk to the south side of Taylor Street. An opening near the north end of the west parapet originally accommodated stairs descending to the Pennsylvania Railroad station.

Despite concrete's early reputation as a permanent, low-maintenance material, the aging Gay Street Bridge has required numerous repairs. It underwent a major rehabilitation in 1971, the details of which were not found in researching this report. Recent inspections of the bridge cited the poor condition of its piers and columns, and noted scaling and spalling throughout. Most recently, the bridge was closed for two months in late 1997 while crews installed an expansion joint to control heaving in span No. 5 and replaced the bituminous wearing surface across the entire bridge.11 Safety netting under span No. 5 currently protects traffic on Mill Street from falling concrete, suggesting that the bridge may need more extensive rehabilitation.

Brief History

The first Gay Street bridge, erected by the Phoenix Iron Company, was situated slightly west of the present structure. On opening day, 19 November 1883, Phoenix Iron officials proved that the high viaduct was capable of bearing great loads by packing a number of the "company's horse-drawn trucks with pig iron and trundle them across the bridge, halting at the head of the procession at the north side of the bridge, until as many of the 100 vehicles as possible had been jammed onto the structure... a severe test for any bridge, of the viaduct type construction as it was (in those days) of iron."12 The bridge had wrought-iron Phoenix columns with 6" and 8" Ibeams, channels, and angles. The structure remained unaltered until the late 1910s, when the Phoenix Bridge Company, a subsidiary of Phoenix Iron, fabricated steel framing in which concrete was poured for a new roadway deck. However, this was a temporary repair for a bridge that had outlived its usefulness.

The borough council and the public were vaguely aware of the old bridge's condition, but it was clearly brought to their attention on 10 January 1922. On that date, bridge keeper James Doran reported to Ellis that the sidewalks were settling. Soon after, Ellis inspected the structure and found numerous faults such as sheared-off rivet heads and missing sidewalk brackets. The sidewalks were immediately closed and the entire span was condemned later that year. Planning and construction for a new bridge was a critical issue because neither the borough of Phoenixville nor Chester County had sufficient funds. In March 1924, the County Commissioners floated bonds worth $500,000 for two projects, the Gay Street Bridge and Pyle's Twin Bridges near Chadds Ford.

Ellis began studying the alignment of a new Gay Street Bridge in late 1922 and created a preliminary design. The bridge's detailed design was the work of Henry H. Quimby, appointed consulting engineer by the County Commissioners on 7 January 1924,13 Quimby was born in nearby Womelsdorf, Berks County, in 1858. Around 1876, he secured employment as an office boy in the Phoenix Iron Company, eventually becoming a civil engineer with its Phoenix Bridge division. Among the numerous company bridge projects Quimby was responsible for was the original Gay Street Bridge. In 1900, Quimby left his Phoenixville residence for Philadelphia, accepting the position of Chief Engineer with the Philadelphia Rapid Transit Company to oversee elevated railway construction. Within several years, he became Assistant Engineer in the city's Department of Public Works and Bureau of Surveys, where he assisted Chief Engineer George S. Webster in the design of a number of Philadelphia's largest bridges, including the Passayunk Avenue Bridge over the Schuylkill River and the Walnut Lane Bridge over Wissahickon Creek. The latter structure had the world's longest concrete arch span when completed in 1908, and no doubt enhanced Quimby's reputation as a consulting engineer. On 25 June 1948, he died in Philadelphia after suffering a stroke at age ninety.

Harry Kaler Ellis was born in Phoenixville on 5 January 1887. While attending Phoenixville High School, Ellis worked part-time jobs at the Heine Boiler Works, in the Phoenix Iron Company's structural shops, and in the drafting rooms of Pencoyd Iron Works. Ellis received his civil engineering degree from Lehigh University in 1909. Before returning to Phoenixville in 1920, Ellis worked in several capacities with numerous public offices and private engineering companies. It is quite likely that Ellis met Quimby during his employment in Philadelphia's Department of City Transit and Department of Public Works, where he was responsible for bridge maintenance. Ellis also worked for private firms such as the Seaboard Air Line Railway, Virginia Bridge Company, and Belmont Iron Works. He served three terms as Chester County Engineer in the 1920s and 1930s, and between 1927 and 1932 was an engineer with the Phoenix Bridge Company. He retired from Bethlehem Steel Company in March 1958 after twenty-two years of service. He died in Fort Myers, Florida, at the age of seventy-five.

On 8 May 1924, the county controller advertised for bids on the Gay Street Bridge project. The Chester County commissioners opened three separate bids on 16 June. The Robert E. Lamb Company submitted the highest bid at $340,014; the next highest was $293,918 from the Whiting-Turner Construction Company; and Hoover-Ryan Construction Company's low bid came in at $279,900. The contract was awarded to Hoover-Ryan on 21 July 1924 and construction began the next day. David B. Hoover, co-owner of the firm, had erected numerous structures in the surrounding area, including the bridge over the Brandywine at Downingtown, one bridge in Montgomery County, and three bridges in Delaware County. Hoover-Ryan engaged several subcontractors, including the Raymond Concrete Pile Company of New York for the foundations, Phoenix Iron for the steel arches, and the Blaw-Knox Company for centering of the arches over the Pennsylvania Railroad's tracks.

Construction of the Gay Street Bridge proceeded with complications that resulted in cost overruns. Excavations for several of the pier foundations hit obstructions, and two piers had to go deeper than the plans specified. Pier No. 11 presented difficulties because of its proximity to the Pennsylvania Railroad's tracks. Diggers at pier No. 7 hit the borough's sewer pipe, and other excavations collided with gas and water pipes, old brick sewers, an old well, and a fire plug. Extra time and money was needed to solve or lessen the difficulties, driving up the cost of the project by $14,924.28. The project's construction phase was scheduled for sixteen months, but dragged on for an additional ten.

Due to its size and scale, thousands of pounds of materials were required for the bridge, which at the time of its construction was the largest and most expensive county-built structure. Ellis estimated that 10,553 cubic yards of stone, 5,592 cubic yards of sand, and 61,130 bags of cement were used in the bridge. The breakdown of the steel provided by the Phoenix Bridge Company was estimated at: steel, arches, and bracing, 233,300 pounds; I-beams, 201,400 pounds; and reinforcing rods, 158,000 pounds. Combined with construction cost overruns, the commissioners' desire to economize meant that certain details were altered. For example, they opted not to have a smooth exterior concrete finish. While the commemorative plaques were changed from zinc to bronze at an additional cost of $20, the number of light poles was reduced by eight, saving $240.

On Saturday, 4 September 1926, festivities officially opening the much-delayed Gay Street Bridge consisted of activities sponsored by various civic groups. The Merchants' Association and the American Legion arranged a jubilee celebration complete with a parade, speeches, a band concert, and dancing on the bridge. It was such an anticipated event that on the previous day the Phoenixville Daily Republican had published a special 32-page dedicatory edition describing the tacts and minutiae of the entire project, complete with special pages of advertisements from sponsors and merchants. The new Farmers' and Mechanics' Bank building opened for public inspection, coinciding with the gala bridge event. Many decorated vintage automobiles with Grand Army of the Republic and World War veterans and borough and county officials traveled across the new structure. After the band played, the bridge was open to the public. In the evening, an estimated 800 Ku Klux Klan members marched through the town's business district in honor of the event.

Conclusion

The reinforced concrete Gay Street Bridge constructed from 1924 to 1926 illustrates the collaborative efforts of private enterprise and local government in the borough of Phoenixville in the early twentieth century. As consulting engineer, Henry H. Quimby designed a first-rate reinforced concrete structure containing a large quantity of steel supplied by the Phoenix Iron Company. Reinforced concrete's increased popularity and reliability as a construction material enabled local governments to erect such structures economically. In the process, Phoenixville came away with a record-setting bridge constructed by local unskilled labor, using local materials, and paid for by a Chester County bond issue.

Report of the Historic American Engineering Record by Helen P. Ross, August 1998. Revised and expanded by Justin M. Spivey, March 2001. Full report available here

Participants

- Harry K. Ellis (County Engineer)

- Henry H. Quimby (consulting engineer)

Relevant Web Sites

There currently are no relevant websites listed.

- About this

data sheet - Structure-ID

20087495 - Published on:

13/11/2023 - Last updated on:

14/11/2023