General Information

Project Type

| Function / usage: |

Bus terminal |

|---|---|

| Structure: |

Membrane structure |

| Material: |

Steel structure |

Awards and Distinctions

| 2015 |

entry

for registered users |

|---|

Location

| Location: |

Aarau, Argovia, Switzerland |

|---|---|

| Address: | Bahnhofplatz 4 |

| Coordinates: | 47° 23' 30.95" N 8° 3' 3.28" E |

Technical Information

Dimensions

| width | 39 m | |

| covered area | 1 070 m² | |

| length | 42 m |

Materials

| roof |

ETFE foil

|

|---|---|

| cables |

steel wire

|

| building structure |

steel

|

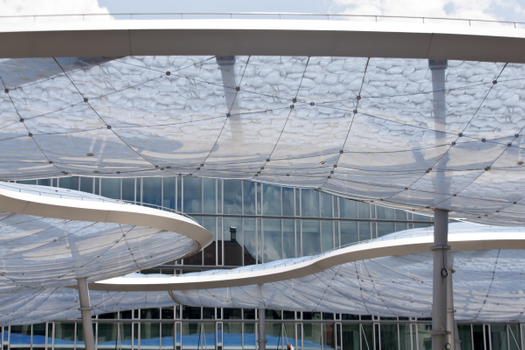

New construction bus yard roof Aarau

Airy and light, the world's largest single-chamber air cushion floats above the new bus station of the city of Aarau (CH). Affectionately, the new bus station roof is called "cloud" by the people of Aarau. A well-organized team of specialized planners and contractors realized this technologically pioneering project in half a year of construction. The high degree of prefabrication and the experience gained during the construction of a mockup helped.

The minimalist supporting structure can be seen to different degrees depending on perspective and lighting conditions due to the multi-layered air cushion, and the roof never looks the same.

Our vision: the roofing of the bus station as functional art in urban space.

Construction

The free-form flat steel grating, supported on 11 steel columns at a height of 7 m above the roadway, covers 1,070 m² and has a central recess. The supports of the roof (tubes 298.5x14.2) are clamped into the steel table and articulated at their bases on the underground parking deck. For optical reasons, these are inclined up to 8° in the direction of the bus platforms.

The star-shaped column heads are integrated at the same level in the flat grid of rectangular tubes (400x200x8) via rigid HV bolted joints. Each column head is connected to 4 to 8 rectangular tubes. The freely formed outer and inner roof edge (355.6x10 tubes) is bolted to the steel grating via short cantilever arms to resist bending and torsion. The curved edge tube pushes were adjusted, positionally fixed, welded in place, and then overlapped.

Behind the V-shaped aluminum screen are the stop plates for the forks of the ropes, the perimeter gutter, and a small "railing" that holds back slipping snow and to which the PPE is attached for inspection and maintenance.

The stainless steel ropes (Ø 8-12 mm), up to 41 m long, span from edge to edge and, together with the 2-part knots at the rope crossings, form a spatial rope net with a free mesh geometry. Because of the only small span of the foils, we distributed the ropes in such a way that the largest dimension of the meshes is limited by an inscribed circle of 150 cm.

The rope net knots, developed on a project-by-project basis, secure the position of the ropes during installation as well as in the unlikely event of a prolonged failure of the supporting air supply.

A particular challenge was to integrate the technical equipment invisibly into the supporting structure. After all, what cloud has sewage pipes, electrical cables and air hoses? We therefore designed the hollow sections as supports for airtight welded-in empty pipes and coupled them in a media-tight manner at the level of the HV bolted joints with O-rings. Since the wastewater pipes are deflected in the area of the column heads with a knee pipe, the column heads are flared conically and the column bases end under floor in a media shaft. Except for the wrap-around V-shaped aluminum fascia, all components are load-bearing, form-fitting or media-sealing. All connections and reinforcements are designed "at sight."

The steel structure is designed so that one of 11 supports can fail. So that assembly could be carried out quickly in spring 2013, the steel table was pre-assembled, welded and dismantled again with geometer support at the straightening yard in Kriens (CH) in winter 2012.

ETFE cushion

The upper blue and lower clear film are printed with bubbles. To achieve a varied design with the largest possible air bubbles, the printing contract was awarded to the company with the largest printing roller available, with a circumference of 1.26 meters. The readable multi-layered design of the roof made of rope nets, printed blue and printed clear ETFE film and the internal table structure creates an interesting and never the same play of light and shadow, visible and hidden, both by day and by night.

The cushion sets absolute standards in terms of impermeability. It has been shown that the air cushion remains inflated even in the event of a 24-hour failure. This is remarkable because both the top and bottom films were assembled on site from three film panels each in a force-fit and airtight manner, with 11 supports penetrating the bottom film.

The blower's job is to maintain the cushion pressure and adjust it to the seasons, but it is mostly just busy circulating the air so that moisture that has diffused in can be absorbed by the dryer. The proven operating costs for the supporting air supply therefore amount to just one Swiss franc per square meter per year. If, despite all precautions, the supporting air supply should nevertheless fail for a longer period, flexible Teflon hoses between the two films ensure that no water pockets form on the upper film.

Sustainability

All materials used on the project are single-grade and extensively recyclable, including the ETFE film. The visual value of the Bushof roof will be preserved for a long time: on the one hand, because the steel inside remains clean for a long time, and on the other hand, because of the permanently anti-adhesive surface of the ETFE film (low surface tension). Dirt cannot adhere to it and is simply washed off by the rain. Even films that have been exposed to the weather for many years are usually clean and can hardly be distinguished from new films. Maintenance for the roof is limited to washing down the supports, visual inspections and the annual replacement of the filter mat in front of the intake grille of the economical air circulation system. A C4-long coating protects the steel from corrosion; this is one corrosion protection class higher than required to account for the 50-year service life.

Conclusion

The Aarau bus yard roof sets new standards in the formation of urban functional buildings - a place was created that makes people happy and is gladly accepted by the citizens of Aarau.

Explanatory report by formTL ingenieure für tragwerk und leichtbau GmbH for submission to the Ulrich Finsterwalder Ingenieurbaupreis 2015

Participants

Relevant Web Sites

There currently are no relevant websites listed.

Relevant Publications

- (2014): Eine Wolke aus Stahl, Folie und Luft - Das Bushofdach Aarau. In: (2014): Ingenieurbaukunst 2015. Ernst & Sohn, Berlin (Germany), ISBN 9783433030967, pp. 70-79.

- About this

data sheet - Structure-ID

20066261 - Published on:

24/06/2014 - Last updated on:

17/05/2015