One-off formwork for gigantic reinforced-concrete capsule

For the extension to the Polish university of Rzeszów, Harsco Infrastructure has come up with a unique formwork solution. A gigantic capsule was constructed with a clever combination of standard formwork systems and special Napla formwork elements.

Media

With a population of just under 180,000, Rzeszów is an important municipal centre in the southeast of Poland close to the border with Russia. The university, a merger of formerly separate institutes, was founded in 2001 and ever since has had a growing number of undergraduates. It is now branching out and investing in "futuristic” faculties including a new Centre for Microelectronics and Nanotechnology. The general contractor for the project is the Swedish Skanska Group which commenced work in May 2010. Involved right from the start was Harsco Infrastructure as designer and supplier of in some cases highly sophisticated formwork solutions.

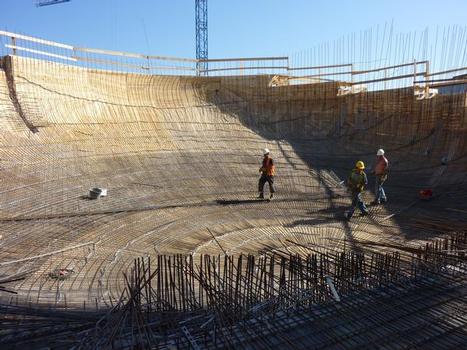

The new L-shaped, four-floor building encloses a space of around 462,000 m3 and will be supplemented by an underground car park for 296 vehicles. Most of the wall shuttering is made up of Manto large-area formwork while for the slabs it is mainly Topflex wooden beam formwork. In terms of formwork complexity it is the cylindrical walls of the seven lecture rooms that attract most attention; these extend beyond the building’s contour and, together with slab and soffit, constitute a gigantic capsule from in-situ concrete running along the whole length of the building.

The biggest challenge facing Harsco Infrastructure’s formwork engineers was to come up with a practicable and as cost-effective as possible technique for producing these complex arched parts. Any solution would not only have to address the stiff engineering challenges, it was also important right at the design state to simulate all the shuttering processes and hence inhibit interference with work on the neighbouring parts under construction. This was a task handled in close coordination between Skanska and Harsco engineers. Harsco Infrastructure developed a detailed plan for the successive formwork stages besides supplying all the drawings and static computations for the special arch-shaped Napla elements. "Napla” stands for "nail plates,” since the core idea is for wooden elements of identical thickness and at any angle to be tied into very tight knots with nail plates. Together with a local timber construction company, the basic prefabricated parts of the wooden formwork were delivered to the site and with the nail plates assembled to form shuttering elements and given a lining. In this way, any desired formwork could be created for a perfect fit.

Five concreting steps

All the cylindrical formwork elements constituting the capsule walls were mounted on work platforms carried by ID 15 towers to ensure safe load discharge throughout the construction phases. Because of the capsule’s vast dimensions and unusual geometry comprising large circular sections, the whole capsule was put together in five separate stages. In the first, the floor was concreted, this was followed by the shotcreted arch between the slab and vertical walls, the third phase consisted of the circular vertical wall surfaces produced with the aid of circular Ronda formwork. Phase four: the arched crossover between the vertical wall surfaces and what would be the slab was shuttered and concreted. The internal formwork was made up of Napla elements mounted inside the capsule on a scaffold comprising Modex modular scaffolding. The external formwork (again Napla) was partly supported by suspended brackets and partly was mounted on the projecting formwork of the capsule’s floor slab. In the final phase, the capsule was sealed with a straight soffit surface for which Topmax floor tables were used, these again being supported by Modex scaffolding framed inside the capsule. The whole project went off very smoothly and this, say those in charge, is due to the right-from-the-start very close cooperation between Skanska and Harsco.

Structure Types

- About this

data sheet - Product-ID

6258 - Published on:

13/05/2013 - Last updated on:

30/01/2016