Forming a new airport for Istanbul

On the European side of the Bosporus, 35 km north of Istanbul, a new airport is in the making. Covering 76.5 km², it will be one of the largest in the world. In terms of passenger capacity too, it will be one of the biggest: when fully operational on completion in 2028, it will be able to handle more than 150 million passengers a year.

Media

The new airport is set to become a hub in the region. Several airlines intend siting their headquarters there. In close proximity to the Black Sea, it will have its own port access.

Istanbul's third airport

The new airport will be Istanbul's third. The two now in operation – Ataturk International on the European and Sabiha Gokcen International on the Asian side of the straits – are too small for the increasing numbers of passengers. Ataturk International Airport is too close to the metropolitan sprawl to be extended, and current planning envisages its closure at some time in the near future. So building the new airport is a matter of some urgency.

Up to 90 million passengers a year

By no later than February 2018, only two and a half years into construction, the first of four construction phases is due for completion so that a large part of the airport complex can go operational. By that time three runways and one terminal will be available. These facilities will provide sufficient capacity to handle up to 90 million passengers a year.

Construction area of two million m²

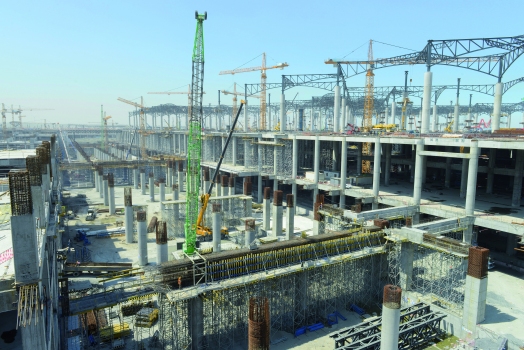

In all, the construction area on this mega-size project is two million m². At times as many as 80 cranes will be in use. Two thirds of the formwork for the first construction phase are supplied by Austrian experts Doka. On this build, the Doka engineers are combining in particular timber formwork beams and load-bearing towers, plus framed formwork and large-area formwork. These formwork systems are in use in many areas, including the runways, terminals, multi-level car-parking facilities and hotels, and the wastewater treatment plant.

The load-bearing tower frames are steel, eminently suitable for high clearances and high loads. On the Istanbul airport build, these circumstances apply for the big downstand beams, which are twelve m above ground level and on which the precast slab is laid. Because they are strong and because of the wide frame span, moreover, the load-bearing towers are very safe. They also help speed up progress overall on the build, because vertical stacking is easy and assembly is a no-tools operation.

30,000 tower frames in use

In all, 30,000 load-bearing tower frames and 100,000 running m of timber formwork beams are in use on this project. Framed formwork and timber-beam formwork systems are used for the walls and columns: Framed formwork with hot-dip galvanised steel frames and framed formwork which is used for crane-lift forming of large areas. Large-area, pre-assembled formwork is used for the columns. A total of 5,000 m2 of framed formwork is in use. Forming and rebar-placement operations are assisted and facilitated by reinforcement platforms.

The stair towers enable the site-crew members to reach their workspaces quickly and in safety. Essential safety is provided by more than four km of guardrail. Safety starts with correct set-up and operation of the formwork. That's why the site crew on the new Istanbul Airport build has the on-site support of Doka Formwork Instructors.

Structure Types

- About this

data sheet - Product-ID

7567 - Published on:

05/01/2018 - Last updated on:

05/01/2018