Built from wood as if by magic

Media

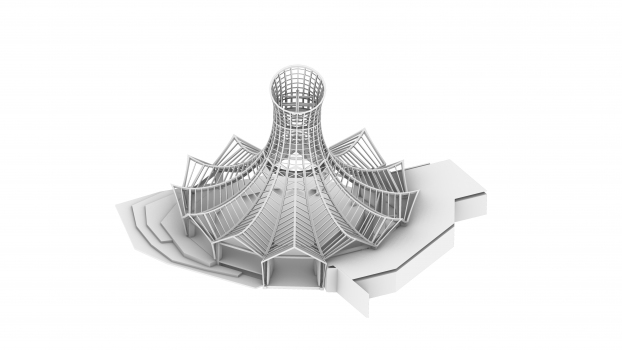

In his design for the new event building on the grounds of the Knies Kinderzoo in Rapperswil/CH, architect Carlos Martinez had a magic cloth floating in front of his eyes. Circus director Franco Knie Senior saw a magic hat in it, and many a visitor is reminded of a circus tent. But whether you see in it a magic hat, a circus tent or a magic cloth, the structure is magical in any case!

Magical is not just the appearance of the building that has just opened, which will be used for circus performances during the day and as a multifunctional event location in the evening. The entire construction, from planning to assembly on site, is a fantastic example of what is possible in timber construction. A project like this can only be the product of intensive cooperation and is always dependent on a good team. So it was a good thing that everyone involved, from the client Knie to the general planner Ghisleni to the engineers from Pirmin Jung, already knew each other from other projects. This also applied to the free-form experts from Blumer Lehmann, who were brought into the team for the planning and implementation of the fancy shell structure.

Interdisciplinary teamwork

The idea to execute the project in timber construction came from the architects. Lightweight construction, for example with a membrane structure, was out of the question for sound insulation reasons; a concrete structure would have been too heavy. The decisive factor, however, was a significant advantage of timber construction: thanks to the highly efficient element construction method, the timber construction could already be prefabricated in the factory, while concrete foundations and wall construction were still being poured on the building site. This was because the tight time frame turned out to be one of the biggest challenges for the planners. The short assembly time on site also solved another problem for Ghisleni, the general planner: noise pollution for local residents and the animals from Knie's children's zoo was kept to a minimum.

Lifted as if by magic, the cantilevered roof soars to a total height of 26 meters. A complex shell structure, devised by Pirmin Jung's structural engineers, made the special roof shape possible. The wooden folding structure is held together by wooden compression rings and a concrete ring, and by unfolding it was possible to raise it to such an extent that the interior is even suitable for trapezoidal numbers. The strictly rotationally symmetrical shape enabled the economical production of twelve identical and twelve mirrored wooden elements; two roof elements each make up a pair, which is supported on the niches in the concrete tension ring at one of the twelve valley low points. The crowning glory is the so-called "hat", which forms the conclusion as a special element.

The free-form specialists at Blumer-Lehmann AG already supported the planners in the technical execution of the geometry and created a mock-up on which the parties involved could clarify further steps for the detailed execution and production. For the detailed planning, Blumer Lehmann modeled all components in 3D. On the parametric model, the elements could be precisely planned and pre-programmed. In this way, cable ducts for the building services were already left out of the elements in the planning phase. Possible collisions in the production or assembly process could already be identified and eliminated on the 3D model.

Prefabrication down to the smallest detail

The elements were completely prefabricated in the factory halls at Blumer Lehmann. "The special thing about this project is the combination of element construction and free form. In addition: all 24 elements are double-curved. This is also special because the curvature affects the entire elements, not just individual supporting ribs," recalls Jan Hempel, project manager at Blumer Lehmann. The ribs and cross ribs are made of glulam. After the elements had been hammered out, they were given double diagonal formwork 24 millimeters thick, which was bent and nailed by hand. The wood used is native spruce, which was used by the planners in the complex construction so close to nature that the material can fully develop its strengths.

The roof cladding was also intended for prefabrication in Blumer Lehmann's factory planning. Thus, the characteristic roof shingles made of zinc sheet were already applied in the factory by the building plumbing department. On the construction site, only the valley joints had to be sealed and the flashings fixed during installation.

Since sound insulation and acoustics played a major role, the shell structure erected from the 24 elements was completely clad from the inside. For this, 470 acoustic panels had to be prefabricated in Blumer Lehmann's factory halls - made of three-layer panels bent in the shape and provided with a perforation.

Safety despite components weighing tons

Assembly on site was one of the major challenges of the project, due to the dimensions of the individual components, the heavy loads of the roof elements weighing up to four tons, and the accuracy of fit when joining the components. Not least because of the (bad) weather, which unfortunately did not cooperate during the assembly of the magic hat. Ensuring safety during assembly was therefore one of the biggest tasks of the site manager and project management. In order not to endanger the erectors unnecessarily, the "last meters" of the magic hat had already been combined into one element in the planning stage and prefabricated completely as a special component, i.e. including roof work here as well. The "hat", weighing almost 20 tons, was lifted into place, adjusted and fixed in place using a special crane. Circus director and builder Franco Knie Senior was visibly thrilled: "I'm used to the circus being set up and dismantled quickly, but what was accomplished here is simply incredible!"

|

Building board |

|

|---|---|

|

Project: |

Knee's magic hat |

| Location: | Rapperswil/CH |

| Building owner: | Gebr. Knie Swiss National Circus AG, Rapperswil/CH |

| Architecture: | Carlos Martinez Architects, Berneck/CH |

| General Planner: | Ghisleni Partner AG, Rapperswil/CH |

| Supporting structure: | Pirmin Jung Schweiz AG, Frauenfeld/CH |

| Timber construction: | Blumer-Lehmann AG |

| Type of project: | Event construction, leisure & sports |

| Construction method: | Freeform |

| Services: | 3D model, factory design timber construction and facade, implementation |

| Execution: | 12/2019 - 8/2020 |