Innovative Network Tied Arch Solution to Spanning the Mississippi River

|

|

|||||||||||

Bibliographic Details

| Author(s): |

Martin Furrer

Greg Hasbrouck |

||||

|---|---|---|---|---|---|

| Medium: | conference paper | ||||

| Language(s): | English | ||||

| Conference: | IABSE Symposium: Engineering for Progress, Nature and People, Madrid, Spain, 3-5 September 2014 | ||||

| Published in: | IABSE Symposium Madrid 2014 | ||||

|

|||||

| Page(s): | 1330-1337 | ||||

| Total no. of pages: | 8 | ||||

| Year: | 2014 | ||||

| DOI: | 10.2749/222137814814067545 | ||||

| Abstract: |

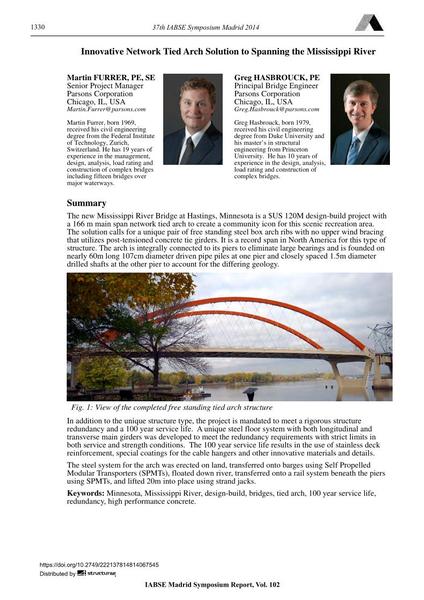

The new Mississippi River Bridge at Hastings, Minnesota is a $US 120M design-build project with a 166 m main span network tied arch to create a community icon for this scenic recreation area. The solution calls for a unique pair of free standing steel box arch ribs with no upper wind bracing that utilizes post-tensioned concrete tie girders. It is a record span in North America for this type of structure. The arch is integrally connected to its piers to eliminate large bearings and is founded on nearly 60m long 107cm diameter driven pipe piles at one pier and closely spaced 1.5m diameter drilled shafts at the other pier to account for the differing geology. Fig. 1: View of the completed free standing tied arch structure In addition to the unique structure type, the project is mandated to meet a rigorous structure redundancy and a 100 year service life. A unique steel floor system with both longitudinal and transverse main girders was developed to meet the redundancy requirements with strict limits in both service and strength conditions. The 100 year service life results in the use of stainless deck reinforcement, special coatings for the cable hangers and other innovative materials and details. The steel system for the arch was erected on land, transferred onto barges using Self Propelled Modular Transporters (SPMTs), floated down river, transferred onto a rail system beneath the piers using SPMTs, and lifted 20m into place using strand jacks. |

||||

| Keywords: |

bridges redundancy high performance concretes HPCs design-build tied arch 100-year service life Mississippi River Minnesota

|

||||