Design and detailing of durable and sustainable Post-Tensioning structures with polymer ducts according to fib bulletin 75

|

|

|||||||||||

Bibliographic Details

| Author(s): |

Klaus Lanzinger

(General Technologies, Inc., Stafford, TX, USA)

Larry Krauser (General Technologies, Inc., Stafford, TX, USA) |

||||

|---|---|---|---|---|---|

| Medium: | conference paper | ||||

| Language(s): | English | ||||

| Conference: | IABSE Symposium: Construction’s Role for a World in Emergency, Manchester, United Kingdom, 10-14 April 2024 | ||||

| Published in: | IABSE Symposium Manchester 2024 | ||||

|

|||||

| Page(s): | 1218-1224 | ||||

| Total no. of pages: | 7 | ||||

| DOI: | 10.2749/manchester.2024.1218 | ||||

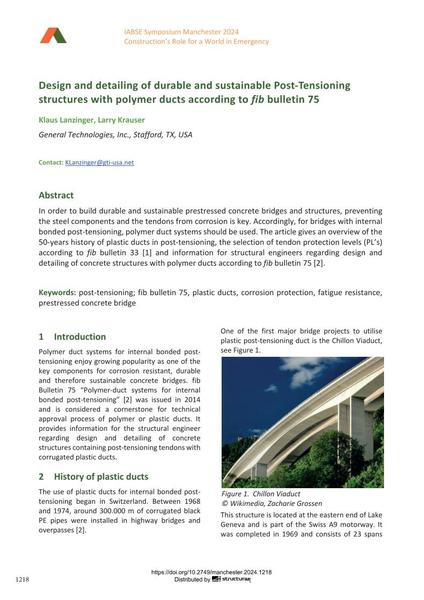

| Abstract: |

In order to build durable and sustainable prestressed concrete bridges and structures, preventing the steel components and the tendons from corrosion is key. Accordingly, for bridges with internal bonded post-tensioning, polymer duct systems should be used. The article gives an overview of the 50-years history of plastic ducts in post-tensioning, the selection of tendon protection levels (PL’s) according to fib bulletin 33 [1] and information for structural engineers regarding design and detailing of concrete structures with polymer ducts according to fib bulletin 75 [2]. |

||||

| Keywords: |

corrosion protection prestressed concrete bridge fatigue resistance post-tensioning fib bulletin 75 plastic ducts

|

||||