General Information

| Completion: | 1901 |

|---|---|

| Status: | in use |

Project Type

| Structure: |

Flat-slab buttress dam |

|---|---|

| Function / usage: |

Irrigation & industrial water dam |

| Material: |

Steel dam |

Awards and Distinctions

| 1992 |

for registered users |

|---|

Location

| Location: |

Redridge, Houghton County, Michigan, USA |

|---|---|

| Impounds: |

|

| Replaces: |

Redridge Timber Crib Dam (1894)

|

| Coordinates: | 47° 8' 56.49" N 88° 45' 51.30" W |

Technical Information

Dimensions

| height | 22.57 m | |

| length | 306.83 m |

Materials

| dam structure |

steel

|

|---|

Significance (HAER Report)

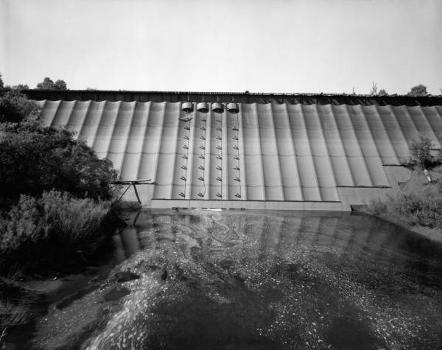

The water supply impounded by the log dam, built by the Atlantic Mining Companjty across the Salmon Trout River in 1894, proved inadequate when the Baltic Mining Company built a stamp mill on Lake Superior just west of the river. Accordingly, the two mining companies decided to jointly build a new dam and share the larger water supply. Because of the lack of suitable stone in this region, they decided to build a steel gravity dam, making this structure only the second dam of that design in the United States and the first of any significant size. It was preceded by a 46 foot high, 184. foot long dam near Ash Fork, Arizona, constructed by the V7isconsin Bridge and Iron Company in 1897-1898. The Redridge Dam was designed by J. F. Jackson, engineer for the Wisconsin Bridge and Iron Company, with F. Foster Cromwell, hydraulic engineer from New York, serving as the consulting engineer. The entire project cost $150,000, with the foundations accounting for $90,000 of the total. The excavation work was performed by Atlantic Mining Company employees under the direction of F. G. Coggin, Jr., superintendent of the company's stamp mill. The contracting firm of Prendergast and Clarkson of Chicago did the concrete work. while the steel was fabricated and erected by the Wisconsin Bridge and Iron Company. Overall, the structure is 1,006 feet long and two earth embankment wings with concrete core walls. The center portion of the dam required 8,000 cubic yards of concrete, while another 2,000 cubic yards was used in the core walls, and 500 tons of steel plates and girders were used. The main dam rests on a solid concrete foundation 64 feet thick, varying in height from 14 feet to 38 feet, resting on bedrock. It is comprised of five main sections, with the tallest or center section standing 74 feet high. The dam consists of steel boilerplates, 8 feet by 16 feet, riveted and caulked, with a concave shape on the upstream side. In the lower section of the dam, these plates are three-sixteenths of an inch thick and rest directly against the concrete base, while in the upper portion they are three-eighths of an inch thick and are supported by parallel inclined steel I-beams 2 feet deep, which in turn are supported by heavy triangular frameworks of inclined steel columns and struts. The upper portion of the dam is inclined at an angle of 45 degrees from the water. The flow of water from the dam to the two mills was controlled by three 24-inch intakes, with the two on the west end of the dam connected to a 38-inch riveted steel pipeline leading to the Baltic mill some 2,200 feet away. , In addition, there are four 24-inch discharge pipes in the center of the concrete base, each fitted with a sliding external gate and a gate valve. Finally, there was a waste weir built approximately 350 feet long, tapering in width from 50 feet to 30 feet, leading to a timber flume, 30 feet wide, 4 feet deep, and 400 feet long, discharging back into the river. This remarkable structure created a reservoir of 600 million gallons, ample storage for the two mills, which used an average of 25.5 million gallons daily.

Sources / Fourther Reading

F. H. Bainbridge, "Structural Steel Dams," Engineering News, LIV (19o05), pp. 323-324; F. H. Bainbridge, "Structural Steel Dams," Journal of the Western Society of Engineers, X (1905), pp. 615-631; Houghton Daily Mining Gazette, October 7, 1967, pp. 1, 9; J. F. Jackson, "Copper Mining in Upper Michigan," Journal of the Western Society of Engineers, VIII (February 1903), pp. 15-16; J. F. Jackson, "Four Steel Dams: Their Design and History/" Engineering News-Record, CIV (1930), p. 281; James Dix Schuyler, Reservoirs for Irrigation, Water Power, and Domestic Water Supply (New York, 1912), pp. 456-459; Stevens, I (1900), pp. 254-256; C. Maxwell Stanley, "Why Not Steel Dams?", Engineering News-Record, CIX (1932), pp. 652, 658; "The Redridge Dam," Engineering News, XXXXVI (1901), pp. 101-102

Report transmitted to HAER by Jean P. Yearby, from data compiled by Charles K. Hyde, 1984.

Excerpt from Wikipedia

The Redridge Steel Dam is a steel dam across the Salmon Trout River in Redridge, Houghton County, Michigan. Completed in 1901, it is a flat slab buttress dam constructed of steel, a relatively rare material for construction of dams, which are typically made of earthenworks, concrete, or masonry. Most sources indicate it was one of only three such dams constructed in the United States, the other two being the Ashfork-Bainbridge Steel Dam (1898, Arizona) and the Hauser Lake Dam (1907, Montana), the last of which failed within a year of construction.

History

In 1894, prior to the construction of the steel dam, the Atlantic Mining Company built a timber crib dam across the Salmon Trout River. The dam created a reservoir which supplied water to the Atlantic stamp mill which extracted copper from ore-bearing rock. With the growth of the Atlantic stamp mill and the construction of the Baltic Mining Company mill nearby, this reservoir proved to be insufficient, and in 1901 the steel dam was built. It was designed by J. F. Jackson and built by the Wisconsin Bridge and Iron Company. The old timber crib dam remained in place, submerged, upstream of the steel dam. A system of spillways, sluices (or launders as they are referred to in contemporary texts), and pipes brought water downhill to the stamp mills. The dam itself measures 74 ft (23 m) high at its center and extends for a length of 1,006 ft (307 m) across the river. Access to the reservoir was shared by the Atlantic and Baltic mines, which had a common board of directors.

The dam operated for several decades, until the mines closed. After that time, the dam was no longer maintained. On Easter morning of 1941, the spillway behind the dam broke, causing a flood. There was little damage to the steel part of the dam, but with the mining operations stopped, the dam owners had the spillway valves opened. However, there were still incidents of overtopping, and the Copper Range Company (successor to Atlantic Mine Company and owner of the dam) had large holes cut in it in 1979 so that it would not retain water. This lowered the level of the reservoir, revealing the earlier timber dam.

Ownership of the dam was transferred to Stanton Township in 1992. Fears that the timber dam might fail and Michigan's Department of Environmental Quality considering the dam a "significant hazard" forced the township to consider renovating the dam in 2001. Five options were proposed for a long-term fix for the dam. These options ranged from repairing the steel and wooden dams for $311,000 to restoring/ reconstructing the entire structure for over a million dollars. Stanton Township could not afford to do any of the proposed options, so another option was sought out. A short-term fix was found to make the dam safer. The upper 13 feet of the wooden structure was removed in 2004 to bring the water level down and relieve some of the pressure. A more permanent repair is still needed. A recent study by a team of students from Michigan Technological University determined that both dams are likely to remain safe for the foreseeable future.

Construction information

Steel dams use relatively thin steel plates in contact with the water body, with a framework of steel behind them transmitting the load to the ground. The plates are slanted upwards in the direction of water flow, so that the weight of the water puts compressive forces on the girders holding the plates up. This transmits force to the ground without the bending moment that a vertical wall of plates would engender. It was believed at the time that these dams could be constructed faster and more cheaply than masonry dams.

Geography and site information

Redridge is in Houghton County, one of the more rugged counties in Michigan, and access to the dam site is relatively challenging, although there is a history of Michigan Technological University students making pilgrimages to the site, especially those interested in industrial archaeology.

Historic designations

- National Register of Historic Places, listed April 2, 1992

- Michigan Historic Civil Engineering Landmark, designated in 1985

Text imported from Wikipedia article "Redridge Steel Dam" and modified on 15 February 2021 according to the CC-BY-SA 3.0 license.

Participants

Relevant Web Sites

Relevant Publications

- (1984): Great American Bridges and Dams. A National Trust Guide. John Wiley & Sons, New York (USA), pp. 210-211.

- About this

data sheet - Structure-ID

20001384 - Published on:

25/03/2001 - Last updated on:

20/10/2015