Stress redistribution in bridges built using the balanced lift method

|

|

|||||||||||

Détails bibliographiques

| Auteur(s): |

Dominik Suza

Johann Kollegger |

||||

|---|---|---|---|---|---|

| Médium: | papier de conférence | ||||

| Langue(s): | anglais | ||||

| Conférence: | IABSE Conference: Elegance in structures, Nara, Japan, 13-15 May 2015 | ||||

| Publié dans: | IABSE Conference Nara 2015 | ||||

|

|||||

| Page(s): | 126-127 | ||||

| Nombre total de pages (du PDF): | 6 | ||||

| Année: | 2015 | ||||

| DOI: | 10.2749/222137815815774223 | ||||

| Abstrait: |

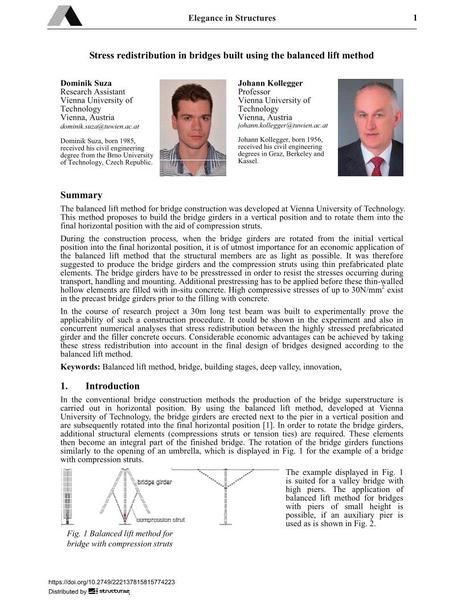

The balanced lift method for bridge construction was developed at Vienna University of Technology. This method proposes to build the bridge girders in a vertical position and to rotate them into the final horizontal position with the aid of compression struts. During the construction process, when the bridge girders are rotated from the initial vertical position into the final horizontal position, it is of utmost importance for an economic application of the balanced lift method that the structural members are as light as possible. It was therefore suggested to produce the bridge girders and the compression struts using thin prefabricated plate elements. The bridge girders have to be presstressed in order to resist the stresses occurring during transport, handling and mounting. Additional prestressing has to be applied before these thin-walled hollow elements are filled with in-situ concrete. High compressive stresses of up to 30N/mm² exist in the precast bridge girders prior to the filling with concrete. In the course of research project a 30m long test beam was built to experimentally prove the applicability of such a construction procedure. It could be shown in the experiment and also in concurrent numerical analyses that stress redistribution between the highly stressed prefabricated girder and the filler concrete occurs. Considerable economic advantages can be achieved by taking these stress redistribution into account in the final design of bridges designed according to the balanced lift method. |

||||

| Mots-clé: |

pont rabattement balancé innovation

|

||||