Reconstruction of the “Terfener Innbrücke” in Austria’s Inn Valley

The Terfener Innbrücke reconstruction project on the A12 motorway in the Inntal valley is one of largest bridge construction projects currently being carried out in the west of Austria. For reasons of efficiency and safety, reconstruction of the bridge began in 2018 with a strict construction time frame of three years. The project will see the two existing steel composite bridges replaced by two new bridge support structures made of pre-stressed concrete.

Media

The A12 motorway winds its way through the heart of the Austrian federal state of Tyrol for around 153 km, starting at Kiefersfelden/Kufstein at the German-Austrian border and passing the city of Innsbruck on its way towards the municipality of Zams. The motorway cuts through the Inntal valley, which provides the backdrop for the Inntalbrücke, a bridge measuring roughly 235 m in length. Every day, approximately 60,000 vehicles use this bridge to get from one side of the Inn river to the other.

Bridge was built using the cantilever construction method

The project was implemented using the cantilever construction method. This bridge construction process, which is carried out according to the beam principle, sees the superstructure erected in relatively short sections starting from the piers, using a cantilever carriage.

The Innsbruck area, and therefore also the Terfener Innbrücke, happens to be in an earthquake zone. As such, the structural calculations used for both the bridge support structure and the balanced cantilever carriage had to allow for seismic loads in order to account for the possibility of an earthquake.

The system components of the balanced cantilever carriage could be made available at short notice. The first delivery of materials took place in January 2019. The first concreting process was carried out only two months later.

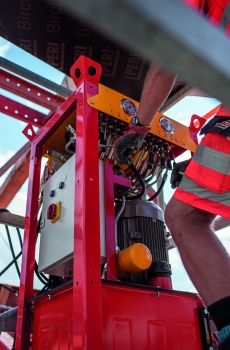

The decision to use the balanced cantilever carriage meant that 5.70-m-long concreting sections could be realised. This resulted in a reduction of only four cycles per bridge support structure: a total of eight during the project. The fact that the system is highly flexible and easy to align meant that the respective segments could be concreted in weekly cycles. What's more, the fully integrated hydraulic unit simplified the process of adjusting and calibrating the formwork from one section to the next. Given the fact it is convenient to operate, the system could be moved to the next cycle quickly and easily.

The presence of the longitudinal cantilevered slab retaining wall in the area of the abutment, which runs from the upper edge of the foundation up to the lower edge of the cantilevered slab, meant that it was necessary to alter the projection of the cross girders in the grate and to have a supporting structure spacing of only 50 cm.

References

Structure Types

- About this

data sheet - Product-ID

7677 - Published on:

06/08/2020 - Last updated on:

06/08/2020