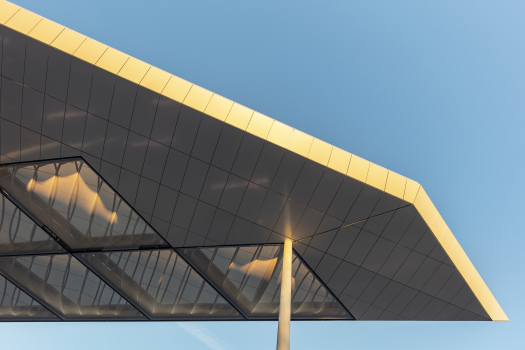

Membrane covering for New Trade Fair South, Dusseldorf

The New Trade Fair South welcomes its visitors in Dusseldorf underneath a spectacular canopy. The 20-meter high, tapered roof is part of the newly designed entrance zone to the south site of the trade fair according to a design by slapa oberholz pszczulny | sop architects. 170 meters in length and 93 meters wide, the polygonal roof made of translucent fiber glass fabric already offers plenty of space for visitors.

Media

Architect Jurek Slapa created a cushion-shaped structure made of fiber glass fabric for this artificial sky which changes its face with the weather during the day and is illuminated in the dark by an exciting light scenography.

A canopy made of steel and membrane

The roof stands on 19 slender concrete pillars and consists of a geometrically rigid steel structure with 94 uniform diamonds. The actual roof cladding appears extremely light. The upper side is covered with a translucent fiber glass membrane that gives the impression of a cloud with its white, rhombic cells. The polyester fabric on the lower side is transparent, allowing a view through the slender construction up to the cloudlike roof. The shape of the surfaces of the two membranes is created by inner steel arches.

Sophisticated cutting- and seam layout

The two roof cladding fabrics differ not only regarding their materiality and transparency. The different materials meet various requirements in terms of load bearing behavior and design: The upper cladding works as weather protection, while the lower mesh fabric is transparent, freeing up a view to the structure and the seam layout. For the cutting pattern generation, various compensation values arise depending on the materiality, so that cutting layouts for both sides of the membrane are applied. Because various angles of inclination also arose from the drainage concept for the diamond structure, 18 different geometries were finally developed for the roof membrane.

Feasibility study for the construction

The formTL engineers were involved in the construction project at an early stage. In coordination with the architecture the feasibility of the diamonds was examined first.

To examine the concept of the structure and the choice of material, pre-static analyses were carried out which made the necessary load data available to be applied to the steel structure.

The choice of material for the two membrane fabrics and the functionality of the structure were also examined, for example regarding drainage at the edges of the diamond bays.

After the tender and the awarding to the membrane experts at Temme // Obermeier, formTL was commissioned again. The task this time was to prepare the final approval and workshop design of the membranes together with the attachment system. Part of the task was to develop a seam layout with little waste. For the visual approval, a 1:1 scale mock-up was created on which the execution of the fabric could be coordinated together with the architects.

References

Structure Types

- About this

data sheet - Product-ID

8010 - Published on:

13/09/2021 - Last updated on:

13/09/2021