First MSM® Swivel Joist Expansion Joint on a German Motorway

Unexpected settlements at the western abutment meant that the Dultenaugraben Bridge between Rheinfelden and Lörrach had to be renovated. For the first time on a German motorway, MAURER installed an MSM® Swivel Joist Expansion Joint with a movement of 550 mm. Thanks to the use of the MSM® sliding material applied in bearing construction, this expansion joint has a service life of 100 years.

Media

MAURER replaces damaged expansion joint on the Dultenaugraben Bridge

The 444-m-long, eight-span Dultenaugraben Bridge is a steel composite structure with one superstructure in each direction of travel. As a section of the A 98 motorway between Rheinfelden and Lörrach, the first superstructure with one lane in each direction was opened in 2002 and the second superstructure was opened in 2010, which enabled two lanes of traffic in both directions.

In 2020, the newer bridge was briefly closed during safety work. Settlements of between 30 and 80 mm had occurred on the western abutments. The transition devices on both superstructures were renovated. These devices, also known as expansion joints, bridge the gap between the bridge superstructure and the abutment. The gap changes in the longitudinal direction of the bridge as a result of temperature changes or loads acting on it.

While it was possible to repair the expansion joint of the southern superstructure, a new construction was used for the northern, older superstructure – the new MSM® Swivel Joist Expansion Joint for the first time on a German motorway.

Solution for challenging bridges

For decades, swivel joist expansion joints have been successfully installed in challenging bridges, for example in the world's longest suspension bridge at 4,608 m, the 1915 Çanakkale Bridge in Turkey. They facilitate movements of up to three metres and possibly more, as well as rotations in all directions. The swivel support bars carry the parallel profiles lying on top, which are also called intermediate beams. The support bars lie at a slight angle to the direction of travel, thus ensuring that the opening and closing bridge movements are evenly distributed over the sealing elements between the steel profiles.

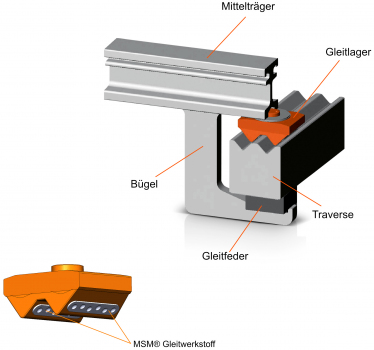

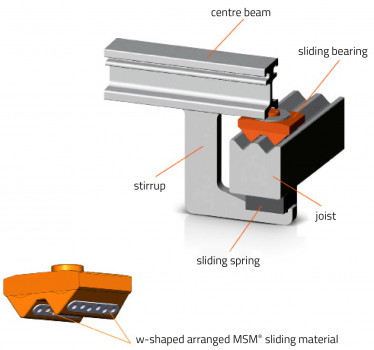

MAURER has fundamentally developed the swivel joist expansion joints. The support of the intermediate beams is entirely new: rather than running in simple elastomeric bearings, the profiles run in w-shaped MSM® bearings. The so-called catamaran support optimises the performance of the entire expansion joint. Thanks to MSM® and the special bearing shape, the profiles slide more easily and precisely over the support bars. This prevents restraints and increases the service life.

The client was Autobahn GmbH des Bundes, and the company, Leonhard Weiss, managed the construction work.

Details of the new MSM® Swivel Joist Expansion Joint

The so-called catamaran support (see graphic) was developed by MAURER in 2020 and is patent pending.

Further development makes the system fit for the future European-wide design rules according to EAD 120113 (European Assessment Document) for multi-seal modular expansion joints.

High forces in the guide bars

Very high forces act in expansion joints. Here, the challenge is not the vertical traffic loads, but the horizontal forces acting on the lateral guide bars of the sliding bearing. These forces not only derive from the control force of the joint, but also from the braking or acceleration forces of the vehicles. The guide bars ensure that the intermediate beams remain "on track", in other words: exactly parallel at all times (transversely to the direction of travel) and with equal distances between them. Given that the bridge can move suddenly within seconds, extremely high compression develops in the relatively small guide bars due to the forces.

In extreme cases, a normal guide "becomes jammed" – which can be compared with a simple drawer that is tilted when pulled open. Such restraints lead to wear in the guide bearing. These negative effects no longer apply with the new swivel support bar.

MSM® guarantees a service life of more than 100 years

MSM® (MAURER Sliding Material) with lubrication pockets is a high-performance sliding material that MAURER has been using in bridge bearings for 20 years. It absorbs much higher compression than the composite material previously used in swivel joist expansion joints, and has been tested for an accumulated sliding displacement of 25 km. For the bearings in the Dultenaugraben Bridge, this means a calculated service life of 270 years according to EAD 120113-00-0107. However, the advantages of MSM® can only be harnessed if the sliding surfaces are in permanent contact with one another. But this has not yet been the case with the swivel support bars, since the sliding elements in the lateral guides were sometimes in contact with the left and sometimes with the right side. This resulted in a so-called gaping joint.

MAURER therefore developed a new w-shaped bearing, technical term "double prism guide". It is possible to imagine the decisive difference by visualising a catamaran: like on two "skids", the profiles easily and precisely slide over the support bars in a tilt-proof way, thus resulting in a very stable guide.

An overview of the benefits of the new MSM® Swivel Joist Expansion Joint:

- Longer service life

- Less maintenance and therefore lower costs

- Less congestion

- More sustainable, as 20% less waste and 50% less CO2 emissions compared to previous swivel joist expansion joints

References

Structure Types

- About this

data sheet - Product-ID

8048 - Published on:

19/02/2024 - Last updated on:

19/02/2024

MAURER SE

MAURER SE