Rehabilitation of Illerkanal Viaduct at Kirchdorf – A Steel Composite and Precast Concrete Structure

|

|

|||||||||||

Bibliographic Details

| Author(s): |

Peter Seitz

|

||||

|---|---|---|---|---|---|

| Medium: | conference paper | ||||

| Language(s): | English | ||||

| Conference: | IABSE Symposium: Engineering for Progress, Nature and People, Madrid, Spain, 3-5 September 2014 | ||||

| Published in: | IABSE Symposium Madrid 2014 | ||||

|

|||||

| Page(s): | 1378-1382 | ||||

| Total no. of pages: | 5 | ||||

| Year: | 2014 | ||||

| DOI: | 10.2749/222137814814067509 | ||||

| Abstract: |

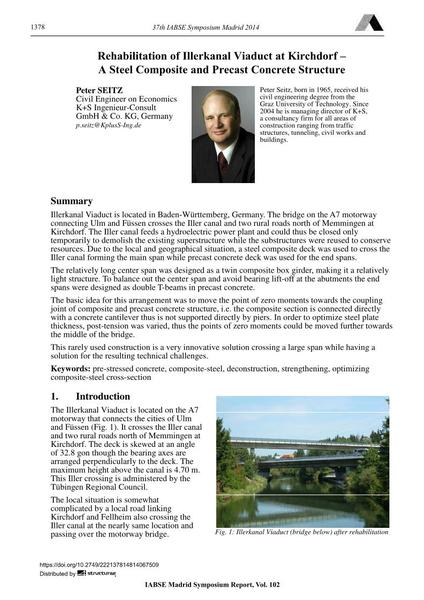

Illerkanal Viaduct is located in Baden-Württemberg, Germany. The bridge on the A7 motorway connecting Ulm and Füssen crosses the Iller canal and two rural roads north of Memmingen at Kirchdorf. The Iller canal feeds a hydroelectric power plant and could thus be closed only temporarily to demolish the existing superstructure while the substructures were reused to conserve resources. Due to the local and geographical situation, a steel composite deck was used to cross the Iller canal forming the main span while precast concrete deck was used for the end spans. The relatively long center span was designed as a twin composite box girder, making it a relatively light structure. To balance out the center span and avoid bearing lift-off at the abutments the end spans were designed as double T-beams in precast concrete. The basic idea for this arrangement was to move the point of zero moments towards the coupling joint of composite and precast concrete structure, i.e. the composite section is connected directly with a concrete cantilever thus is not supported directly by piers. In order to optimize steel plate thickness, post-tension was varied, thus the points of zero moments could be moved further towards the middle of the bridge. This rarely used construction is a very innovative solution crossing a large span while having a solution for the resulting technical challenges. |

||||

| Keywords: |

strengthening pre-stressed concrete deconstruction composite-steel optimizing composite-steel cross-section

|

||||